Aluminum Step Tile Roofing Sheets 1050 3003 1060 1100 1.2mm 3mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

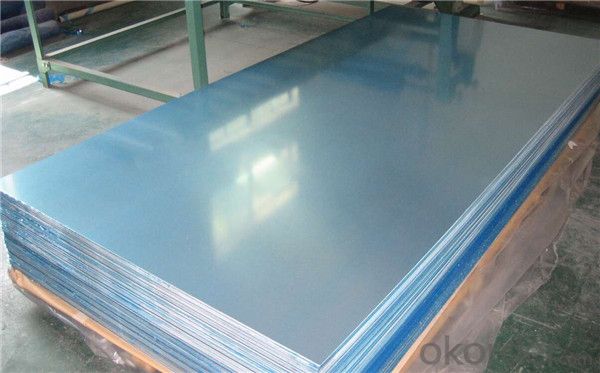

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

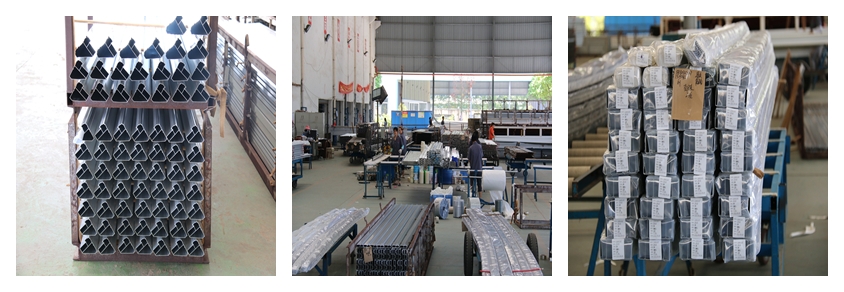

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: Can aluminum sheet be used for automotive body panels?

- Yes, aluminum sheet can indeed be used for automotive body panels. Aluminum is a lightweight and corrosion-resistant material, making it desirable for improving fuel efficiency and increasing vehicle performance. It is widely used in the automotive industry to manufacture body panels, such as hoods, doors, fenders, and roofs, as it offers strength, durability, and design flexibility.

- Q: Can aluminum sheets be used for solar panel frames?

- Yes, aluminum sheets can be used for solar panel frames. Aluminum is a popular choice for solar panel frames due to its excellent strength-to-weight ratio, corrosion resistance, and durability. These characteristics make it a suitable material for supporting and protecting solar panels, which are typically installed in outdoor environments. Aluminum frames provide structural stability and ensure the longevity of solar panels by protecting them from environmental factors such as wind, rain, and snow. Additionally, aluminum is easily recyclable, making it an environmentally friendly choice for solar panel frames.

- Q: How do you prevent fingerprints on aluminum sheets?

- One way to prevent fingerprints on aluminum sheets is by wearing gloves while handling them. Additionally, regularly cleaning the sheets with a gentle, non-abrasive cleaner can help remove any existing fingerprints and prevent new ones from forming.

- Q: What types of aluminum sheets are recommended for use in cold climates?

- <p>Yes, there are specific types of aluminum sheets suitable for cold climates. These include 3003-H14 and 5052-H32 aluminum sheets. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for cold weather applications. 5052-H32 offers high strength and good corrosion resistance, which is beneficial in extreme cold conditions. Both types can withstand low temperatures without significant loss of strength or ductility, ensuring reliability and durability in cold environments.</p>

- Q: What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets can vary depending on the thickness of the sheet and the specific alloy being used. However, in general, a typical bend radius for aluminum sheets ranges from 0.8 to 2 times the thickness of the sheet.

- Q: Can aluminum sheets be powder coated?

- Yes, aluminum sheets can be powder coated. Powder coating is a popular finishing process that involves applying a dry powder to a surface, such as aluminum, and then curing it through heat to create a durable and attractive finish. Aluminum is commonly powder coated due to its lightweight, corrosion-resistant, and versatile nature. The powder coating process provides excellent adhesion to aluminum sheets, resulting in a smooth, even, and long-lasting finish. It also offers a wide range of color options and can be used for various applications, including architectural, automotive, and industrial uses.

- Q: How do aluminum sheets perform in terms of creep resistance?

- Aluminum sheets generally exhibit good creep resistance, especially when compared to other metals. Aluminum has a low melting point and high thermal conductivity, which helps in reducing creep deformation. It also has a fine-grained microstructure that enhances its resistance to creep. However, it is important to note that the creep resistance of aluminum sheets can be affected by factors such as temperature, load, and alloy composition.

- Q: How do aluminum sheets perform in terms of thermal expansion and contraction?

- Aluminum sheets possess a relatively high coefficient of thermal expansion, causing them to expand and contract more than most other materials when subjected to heat or cold. The coefficient of thermal expansion for aluminum is approximately 23 x 10^-6 per degree Celsius. Consequently, for each degree Celsius rise in temperature, aluminum expands by 23 millionths of its original size. This thermal expansion and contraction characteristic of aluminum renders it suitable for various applications where temperature fluctuations are anticipated. For example, in the construction industry, aluminum sheets are commonly utilized for roofing and cladding purposes. These sheets can endure the thermal stresses resulting from changing temperatures without experiencing significant warping or distortion. Additionally, this particular attribute of aluminum makes it an ideal choice for the production of items such as cookware and heat sinks. Aluminum cookware heats up rapidly and evenly due to its high thermal conductivity, while expanding uniformly to prevent warping or deformation when exposed to heat. Similarly, aluminum heat sinks effectively dissipate heat generated by electronic components as they can accommodate thermal expansion without compromising their structural integrity. However, it is important to acknowledge that although aluminum sheets possess favorable thermal expansion and contraction properties, extreme temperature changes can still result in some dimensional alterations. Therefore, careful consideration of the expected temperature variations is essential when designing and utilizing aluminum sheets to ensure their optimal performance and durability.

- Q: What specific tools or equipment are required when working with aluminum sheets?

- <p>When working with aluminum sheets, you'll need a few special tools and equipment. These include sheet metal shears for cutting, a metal file for smoothing edges, a metal straight edge for measuring and marking, and a vise for holding the sheet securely. For bending, a sheet metal brake is essential. Safety gear such as gloves and goggles are also crucial to protect against sharp edges and debris. Additionally, a T-square and a marker are needed for precise measurements and markings.</p>

- Q: I am engaged in line cutting, because the cut aluminum plate conductive block wear more fierce, molybdenum wire is often broken card, I do not know that heroes have unique skills, say, we share. Thanks.

- The contact position between the conductive block and the electrode wire is often changed

Send your message to us

Aluminum Step Tile Roofing Sheets 1050 3003 1060 1100 1.2mm 3mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords