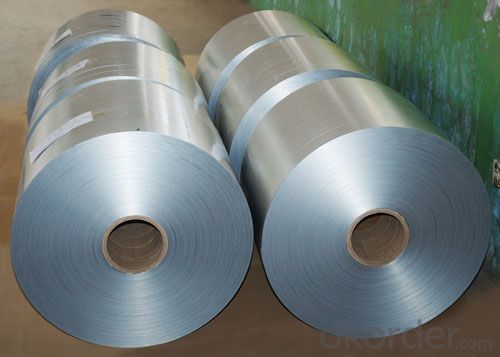

Aluminum Coil Slitting Machine Compatible Aluminum Roofing Sheet 3003 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Roofing Sheet 3003 H14 Of Aluminum Sheet

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: This question asks for guidelines on how to properly store aluminum coils to ensure their safety and longevity.

- <p>To store aluminum coils, follow these steps: Ensure the storage area is clean, dry, and free from dust and moisture. Keep the coils on wooden pallets or racks to avoid direct contact with the ground. Stack the coils with the same size and type to prevent damage. Use protective wrapping or covers to prevent scratches and dirt accumulation. Maintain proper ventilation to prevent condensation. Store coils away from corrosive materials and chemicals. Regularly inspect the coils for any signs of damage or corrosion. By following these guidelines, you can maintain the quality and integrity of aluminum coils during storage.</p>

- Q: How do aluminum coils perform in extreme temperature conditions?

- Aluminum coils generally perform well in extreme temperature conditions. Aluminum has a high melting point, around 660 degrees Celsius (1220 degrees Fahrenheit), which makes it suitable for handling high temperatures. It also has excellent thermal conductivity, meaning it can efficiently transfer heat and cool down quickly in extreme heat conditions. This property is particularly beneficial in applications such as air conditioning systems and refrigeration units, where aluminum coils are commonly used. Moreover, aluminum is known for its resistance to corrosion, which is crucial in extreme temperature conditions. It withstands oxidation and does not easily rust, ensuring the longevity and durability of the coils. This resistance to corrosion is especially important in environments with high humidity or salt exposure, where other metals may corrode quickly. However, it is worth noting that extreme cold temperatures can affect the performance of aluminum coils. Aluminum contracts and becomes more brittle in very low temperatures, which may result in reduced flexibility and potential cracking. Therefore, in extremely cold environments, it is important to ensure proper insulation and protection to prevent any damage to the coils. Overall, aluminum coils are reliable and perform well in extreme temperature conditions, especially in high-temperature applications. Their high melting point, excellent thermal conductivity, and resistance to corrosion make them suitable for various industries and environments.

- Q: What is a better deal?Aluminum Cookware ( Paula Deen)orHard Anodized ( Rachael Ray )

- Neither. For one, stainless steel is the way to go. Secondly, with both of those you're paying more for the celebrity endorsement than you are the quality of the product. Go with All-Clad. If it's too expensive, you're better off deciding on a few pieces that you'll use the most and buying quality rather than an entire set.

- Q: How are aluminum coils used in heating, ventilation, and air conditioning (HVAC) systems?

- Aluminum coils play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. These coils are used in both the condenser and evaporator sections of the system. In the condenser, the aluminum coils help transfer heat from the refrigerant to the surrounding air. The refrigerant, which is in a high-pressure and high-temperature state after being compressed, flows through the condenser coils. As the air from the surroundings passes over these coils, the heat from the refrigerant is transferred to the air. This process helps in cooling down the refrigerant, converting it from a gas to a liquid state. The cooled liquid refrigerant then flows to the evaporator coil. In the evaporator, the aluminum coils assist in absorbing heat from the indoor air. The liquid refrigerant enters the evaporator coils, where it undergoes a phase change from liquid to gas. As the warm indoor air passes over the coils, the refrigerant absorbs the heat, cooling down the air. This cooled air is then circulated back into the room, providing a comfortable indoor environment. The aluminum coils are preferred in HVAC systems due to their excellent thermal conductivity, corrosion resistance, and lightweight nature. These properties ensure efficient heat transfer and improve the overall performance of the system. Additionally, aluminum coils are more cost-effective and environmentally friendly compared to other materials like copper. Regular maintenance and cleaning of the aluminum coils are necessary to ensure their optimal functioning. Over time, dirt, dust, and debris can accumulate on the coil surface, hampering heat transfer and reducing efficiency. Therefore, periodic cleaning is essential to maintain the performance of the HVAC system and extend the lifespan of the aluminum coils.

- Q: What's the color coated aluminum roll?

- Colour coated aluminium coil product information:Product category: polyester coated aluminum coil (PE), fluorocarbon coated aluminum coil (PVDF)Mylar coated aluminum coilIs a kind of anti UV ultraviolet coating, polyester resin is used in the main chain of ester containing polymer polymer as monomer, add alkyd resin, UV absorber according to gloss, can be divided into sub light and high light series. The utility model is especially suitable for indoor decoration and advertisement boards.Fluorocarbon coating aluminum coilFluorocarbon resin is a kind of fluorocarbon resin, which is composed of pigments, alcohols, esters, solvents and assistants. High temperature barbecue film,The molecular structure of the coating is close and has super weatherability. Fluorocarbon coatings can be divided into two kinds: traditional fluorocarbon and nano fluorocarbon coating according to the surface film forming structure.The utility model is especially suitable for the decoration and display of indoor, outdoor decoration, commercial chain, exhibition advertisement, etc. in public places

- Q: What are the standard widths of aluminum coils?

- The standard widths of aluminum coils vary depending on the industry and application, but common widths range from 12 inches to 60 inches.

- Q: should i have a paper between aluminum siding and the wood

- Aluminum siding can be vented with round pop-in perforated vent plugs, these are very easy to install. I would really like to know how do you know there is condensation behind your siding?

- Q: What is the purpose or use of aluminum coil in various applications?

- <p>Aluminum coil is a versatile material used in a wide range of applications due to its properties such as lightweight, corrosion resistance, and high thermal and electrical conductivity. It is commonly used in construction for roofing and siding, in the manufacturing of heat exchangers and radiators, and in electrical applications like transformers and power lines. Aluminum coil is also utilized in packaging, such as food and beverage cans, and in automotive and aerospace industries for lightweight components. Its malleability allows it to be easily shaped and formed, making it an ideal material for various industrial processes.</p>

- Q: how tall is a crushed aluminium soda can compared to a non crushed one.i need measurements in centimeters please.ALSO!! AN IMAGE that actually has both of the two with the measurements would be SUPER HELPFUL

- I recognize that there are places in this world where aluminum beverage cans are very exotic, very rare, and may even be quite expensive. I can also understand that, in such a special place, one may have never actually held one of these objects in your own hands. If you live in such a place, then I can understand why you need to seek assistance on Yahoo Answers. I am, personally, quite surprised that you would have internet access in such a place. For your answer... it depends on how you crush the can but it is quite possible to crush your standard aluminum beverage can to a thickness of fractions of a centimeter.

- Q: What are the typical production volumes for aluminum coil manufacturers?

- The typical production volumes for aluminum coil manufacturers vary depending on the size and capabilities of the specific manufacturer. However, it is common for aluminum coil manufacturers to produce thousands to tens of thousands of tons of aluminum coils annually, catering to the demands of diverse industries such as construction, automotive, and packaging.

Send your message to us

Aluminum Coil Slitting Machine Compatible Aluminum Roofing Sheet 3003 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords