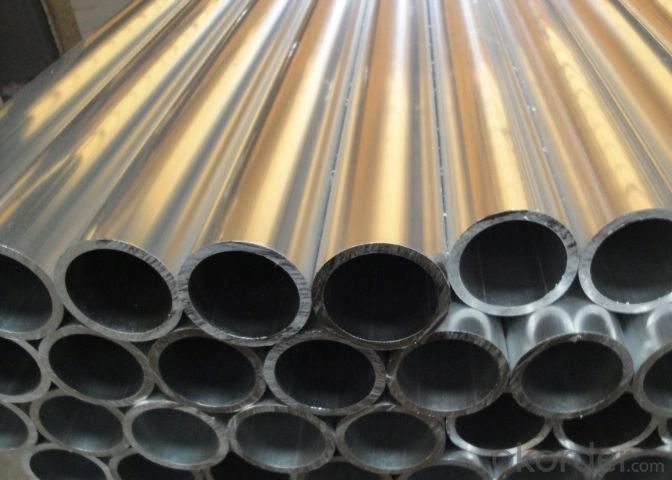

Aluminum Pipes 3005

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Pipe 3005:

1.Specifications of aluminium pipe 3005

1)Alloy:3005;

2)Wall thickness : 0.4mm-80mm ;

3)Outer diameter : 10-900mm ;

4)Length : 6m-9m.

2.Application of aluminium pipe 3005:

aluminum window, door, curtain wall, hand railing, normal aluminum profile, decorative and industrial aluminum profile

3.Features of aluminium pipe 3005:

High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness.

4.Packaging of aluminium pipe 3005:

protection foam heat contracted plastic film,Wooden packing , Metal pallet

- Q: 6063, how to prevent cracking aluminum tube, variant manual bending machine bending machine bending, what should pay attention to?No one knows?

- 6063, aluminum tube plasticity is very good, if you want to bend, it is recommended to return the fire, reduce the hardness, bending after quenching, bend pipe bend can be.

- Q: Are aluminum pipes compatible with different fittings and connectors?

- Yes, aluminum pipes are compatible with different fittings and connectors. Aluminum is a versatile and lightweight material that can be easily connected to various types of fittings and connectors, including threaded, welded, or flanged connections. Its compatibility with different fittings makes it suitable for a wide range of applications in industries such as construction, plumbing, and automotive.

- Q: How can the aluminium tube cooler be welded?

- If relatively thin parts can be used in low temperature aluminum welding wire, with Wei Odin special liquefied gas and then with a small gun, welding can be low temperature aluminum wire, which if the defect is very small, such as small needle, or a small leak, can use temperature of 179 degrees M51 welding.

- Q: Seamed tubes and seamless tubes under which good?

- Seamless aluminium bearing is better than welded aluminum tube, seamless texture is relatively uniform, there will be a small amount of loss in the pipe part of the chemical composition of weld, so the mechanical properties poor and seamless pipe! But not very different! Seamless pipe is recommended if it is used for elbow! The welded pipe is easy to crack! Bending radius is relatively large, then no problem!

- Q: How do aluminum pipes perform in seismic zones?

- Aluminum pipes perform well in seismic zones due to their inherent properties that make them suitable for such environments. Firstly, aluminum is a lightweight material, which means that it has a higher strength-to-weight ratio compared to other materials like steel. This characteristic allows aluminum pipes to withstand seismic forces without excessive deformation or damage. Additionally, aluminum is highly resistant to corrosion, which is crucial in seismic zones where the presence of moisture and soil movement can accelerate the deterioration of pipes. This corrosion resistance ensures that aluminum pipes maintain their structural integrity over time and can withstand the stresses imposed by earthquakes. Moreover, aluminum pipes have excellent ductility, meaning they can deform under seismic forces without fracturing or breaking. This ductility allows the pipes to absorb and dissipate energy during an earthquake, reducing the chance of catastrophic failure and minimizing the risk of gas or fluid leakage. Lastly, aluminum is a flexible material, which means that it can be easily bent and shaped to accommodate ground movements and seismic vibrations. This flexibility allows for the installation of aluminum pipes in curved or irregular paths, enabling them to better withstand the dynamic forces generated during an earthquake. In conclusion, aluminum pipes are a reliable choice for seismic zones due to their lightweight nature, corrosion resistance, ductility, and flexibility. These properties empower aluminum pipes to perform well under seismic forces, ensuring the safety and functionality of piping systems in areas prone to earthquakes.

- Q: Where can I make aluminum pipe?

- Can you buy in what place, if in the Guangdong area, aluminum, gold and aluminum are goodHowever, gold and aluminum mainly sell seamless tubes and solid rods. Other aluminum is relatively small.Other areas are not ripe, not good reply

- Q: Can you tell me what kind of pipe bender is used to bend the aluminum tube? It's not easy to wrinkle or break

- The second point: do not use the hydraulic bender with fast bending speed to avoid the wrinkling and bending of flat tubes! The third point: the use of rotating pipe bending equipment, do not bend and bend the pipe bending equipment! Fourth: special die set for bending aluminium tube!

- Q: Eddy current demonstrator's working principle: why does the magnet fall at different speeds in different aluminum tubes, while the aluminum tubes are the same?

- This is eddy current resistance. Used in a vibration system, that is, electromagnetic damping. The permanent magnet moves in the aluminum tube, and the magnetic field produced by the eddy current in the aluminum tube will resist the change of the magnetic field, that is to impede the movement of the magnet.

- Q: Are aluminum pipes resistant to corrosion?

- Generally, aluminum pipes are resistant to corrosion. When exposed to oxygen, aluminum forms a natural oxide layer on its surface, which helps protect it from further oxidation. This oxide layer acts as a barrier, preventing corrosion. Moreover, aluminum pipes can be coated with different protective finishes or treatments to enhance their corrosion resistance even more, making them suitable for various industries. However, it is important to be aware that certain corrosive environments, such as highly acidic or alkaline conditions, can still cause some level of corrosion on aluminum pipes. Therefore, it is advisable to consider the specific conditions in which the pipes will be used and seek professional advice to ensure proper corrosion protection measures are in place.

- Q: How do aluminum pipes handle water hammer effects?

- Aluminum pipes have good resistance to water hammer effects. Water hammer occurs when there is a sudden change in the flow of water, causing a pressure surge that can lead to pipe damage or failure. Aluminum pipes are lightweight and flexible, which allows them to absorb and dampen the pressure surges caused by water hammer more effectively than rigid materials. The inherent elasticity of aluminum helps to reduce the impact of the sudden pressure changes and minimize the risk of pipe rupture. Additionally, aluminum pipes have a smooth interior surface, which promotes laminar flow and minimizes turbulence. This smooth flow reduces the chances of water hammer occurrence in the first place. Moreover, aluminum pipes have excellent corrosion resistance, including resistance to rust and scale buildup. Corrosion can contribute to water hammer effects by narrowing the pipe's interior diameter and causing flow disruptions. By resisting corrosion, aluminum pipes maintain their structural integrity and help to prevent water hammer from occurring. Overall, aluminum pipes are well-suited to handle water hammer effects due to their lightweight, flexible nature, smooth interior surface, and corrosion resistance. However, it is important to properly design and install the pipe system, including the use of appropriate valves and supports, to further mitigate the potential for water hammer damage.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Pipes 3005

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords