Rolled Aluminum Sheets for Roofing - Aluminum Lidding Foil for Yogurt Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

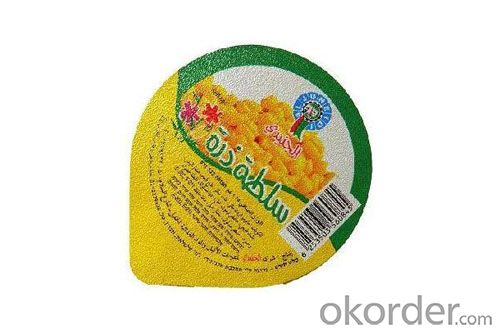

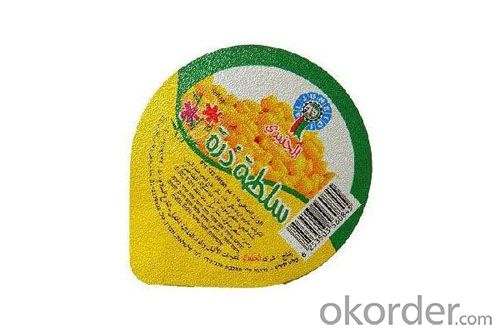

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description of Aluminum Lidding Foil for Yogurt Packaging

*No joint-points per 1000m

*Free samples

*Waterproof and acid attacks

*Surface: With or without gloss/mat effect

*Printed: clear, fastness, non-fade in high-temperature heat seal process

2.Why you want to choose us?

We've been specialized in aluminium foil for more than ten years, we know this product very well, we know what is good, what is the market price.

3.Specification and Application of Aluminum Lidding Foil for Yogurt Packaging

Aluminum alloy no & temper: 8011-O

Width: Max width:60-1000mm;

Thickness: 24mic~60mic;

Coil inner diameter: 76mm;

Printing Color: Less than 8 colors

4. Property of Aluminum Lidding Foil for Yogurt Packaging

pure aluminum 99.9%, First class barrier property against moisture, oxygen,

light corrosion and puncturing.

Strong sealing strength, bonding strength, tear strength and excellent compression

strength.

Non-breakage, non-leakage, non-delaminating, non-poisonous, odorless ,super damp-proof function

5.Pictures of Aluminum Lidding Foil for Yogurt Packaging

6.FAQ

1) How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

2) Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

3) What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: What is the thickness of the aluminum sheets?

- The thickness of the aluminum sheets varies depending on the specific product or application.

- Q: Can aluminum sheets be anodized for corrosion protection?

- Yes, aluminum sheets can be anodized for corrosion protection. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This oxide layer is highly resistant to corrosion and provides a durable and long-lasting protection. Anodizing can be done on various aluminum products, including sheets, to enhance their corrosion resistance, improve their appearance, and increase their lifespan. The process involves immersing the aluminum sheet in an electrolyte solution and applying an electric current, which causes oxygen ions to bond with the surface of the metal, forming the protective oxide layer. Anodized aluminum sheets are widely used in industries such as aerospace, automotive, construction, and electronics, where corrosion resistance is crucial.

- Q: This question asks about the distinctions between aluminum sheets that are produced domestically versus those that are imported.

- <p>Yes, there can be differences between domestic and imported aluminum sheets. These differences may include quality standards, material composition, thickness, surface finish, and price. Domestic sheets are often produced to meet local standards and regulations, while imported sheets may adhere to different international standards. The manufacturing process and raw materials used can also vary, leading to differences in durability, strength, and workability. Additionally, imported sheets might have different certifications or come from countries with lower production costs, which can affect the price. However, it's important to note that not all imported aluminum sheets are of lower quality; some may be of higher quality or have specific characteristics that are not available domestically.</p>

- Q: Can aluminum sheets be easily formed or bent?

- Yes, aluminum sheets can be easily formed or bent. Aluminum is a highly malleable metal, which means it can be easily shaped into various forms without cracking or breaking. This property makes aluminum sheets a popular choice in industries such as automotive, aerospace, and construction, where complex shapes and designs are required. The malleability of aluminum allows for easy manipulation through techniques like rolling, pressing, or bending, enabling the creation of intricate and customized products. Additionally, aluminum's lightweight nature and high strength-to-weight ratio make it an ideal material for forming or bending applications, as it can be shaped without adding excessive weight to the final product.

- Q: Is aluminum sheet fire-resistant?

- Aluminum sheet is not inherently fire-resistant, but it does have certain properties that make it more fire-resistant than other materials. Aluminum has a high melting point, which means it can withstand high temperatures without melting or catching fire. Additionally, aluminum has a low thermal conductivity, meaning it does not easily transfer heat. This makes it more difficult for fire to spread across an aluminum sheet. However, it is important to note that aluminum can still be affected by fire. When exposed to extreme heat, aluminum can weaken and lose its structural integrity. It can also become more susceptible to burning if exposed to certain chemicals or intense flames. To enhance the fire resistance of aluminum sheet, it can be coated with fire-retardant materials or treated with fire-resistant coatings. These additional measures can help to further reduce the risk of fire and improve the overall fire performance of the aluminum sheet. In summary, while aluminum sheet is not completely fire-resistant, it does possess certain characteristics that make it more resistant to fire than other materials. However, it is crucial to take appropriate precautions and use additional fire-resistant treatments when necessary to ensure maximum safety.

- Q: Is aluminum suitable for projects with heavy traffic or frequent use?

- <p>Yes, aluminum sheets can be used in projects that involve high levels of traffic or heavy use. Aluminum is a lightweight, durable, and corrosion-resistant material. It can withstand significant wear and tear, making it suitable for high-traffic areas. Additionally, aluminum is easy to maintain and can be recycled, which is beneficial for long-term projects. However, it's important to consider the specific grade of aluminum and its thickness to ensure it meets the required strength and durability for your project.</p>

- Q: Can aluminum sheet be used for packaging applications?

- Yes, aluminum sheet can definitely be used for packaging applications. Aluminum is widely used in the packaging industry due to its excellent properties. It is lightweight, strong, durable, and malleable, making it ideal for packaging various products. Aluminum sheets can be easily formed into different shapes and sizes, allowing for custom packaging solutions. Additionally, aluminum has excellent barrier properties, providing protection against moisture, gases, and light, which helps to maintain the freshness and quality of the packaged goods. Furthermore, aluminum is non-toxic and can be easily recycled, making it a sustainable choice for packaging applications. Overall, aluminum sheet is a versatile and reliable material for packaging various items, including food, beverages, pharmaceuticals, cosmetics, and many others.

- Q: This question asks about the energy savings achieved by using aluminum sheets in comparison to other materials.

- <p>The energy savings achieved by using aluminum sheets instead of other materials can be significant. Aluminum is lightweight and has excellent thermal conductivity, which means it can reduce energy consumption in applications like building insulation and heat exchangers. For instance, aluminum-framed buildings can save up to 40% more energy than those made with traditional materials due to better insulation properties. Additionally, in industrial processes, aluminum's high thermal conductivity can lead to energy savings of around 33% compared to using copper in heat exchangers. The exact amount of energy saved depends on the specific application and the materials being replaced.</p>

- Q: Are the aluminum sheets suitable for manufacturing solar reflectors?

- Yes, aluminum sheets are suitable for manufacturing solar reflectors. Aluminum is a highly reflective material that can efficiently reflect sunlight, making it an ideal choice for solar reflectors. It has a high reflectivity and low emissivity, allowing it to reflect a significant amount of solar radiation while minimizing heat absorption. Additionally, aluminum is lightweight, durable, and corrosion-resistant, making it suitable for outdoor applications. Its flexibility also allows for easy shaping and forming into various reflector designs. Overall, aluminum sheets provide excellent performance and reliability for manufacturing solar reflectors in solar energy systems.

- Q: How do aluminum sheets compare to copper sheets in terms of conductivity?

- When it comes to conductivity, aluminum sheets and copper sheets have their differences. Copper is known for its exceptional ability to conduct electricity and is considered one of the most conductive metals available. Its high electrical conductivity allows electricity to flow through it with minimal resistance. On the other hand, aluminum, while still a good conductor of electricity, is not as conductive as copper. In fact, aluminum has about 61% of the conductivity that copper possesses. As a result, if high conductivity is a top priority, copper sheets would be the preferred option. However, if cost-effectiveness and lightweight properties are more important, aluminum sheets can still offer adequate conductivity for many applications. Ultimately, the decision between aluminum and copper sheets relies on the specific project requirements and the balance between conductivity, cost, and other factors.

Send your message to us

Rolled Aluminum Sheets for Roofing - Aluminum Lidding Foil for Yogurt Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords