Competitive Price Aluminum Honeycomb Sheets of Aluminum Siding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Honeycomb Sheet Description:

Aluminum honeycomb panels are made of aluminum alloy plates roller coated with PVDF while in the milddle are the aluminum honeycombs which meets the international earonautical standards. This product is specially make with the cold-glue and hot-press technology.

The structural honeycomb core provides strength and consistent rigidity at a very low desity; When bonded to similarly lightweight facings. Every honeycomb cell wall acts like the web of an I-Beam, forming an extremely strong and rigid lightweight composite panel.

2.Main Features of Aluminum Honeycomb Sheet:

Reasonable and stable chemical composition

Accurate tolerance

Nice mechanical property

Standards: EN, ASTM and JIS

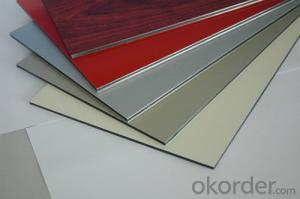

3. Aluminum Honeycomb Sheet Images:

4. Aluminum Honeycomb Sheet Specification:

| Thickness | Unit | 6 mm | 10 mm | 15 mm | 20 mm | 25 mm | ||

| Cover sheet thickness, front | [mm] | 1.0 | ||||||

| Cover sheet thickness, rear | [mm] | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| Weight | [kg/m²] | 4.7 | 5.0 | 6.7 | 7.0 | 7.3 | ||

| Technical properties | ||||||||

| Section modulus | W | [cm³/m] | 2.6 | 4.6 | 14 | 19 | 24 | |

| Rigidity | E@J | [kNcm²/m] | 7.100 | 21.900 | 75.500 | 138.900 | 221.600 | |

| Alloy / Temper of Aluminium Layers | Peraluman alloy (AIMg), H42 acc. EN 573-3 | |||||||

| Modulus of Elasticity | E | [N/mm²] | 70.000 | |||||

| Tensile Strength of Aluminium | R m | [N/mm²] | ≥ 125 | |||||

| 0.2 % Proof Stress | R p0,2 | [N/mm²] | ≥ 80 | |||||

| Elongation | A 50 | [%] | ≥ 5 | |||||

| Linear Thermal Expansion | α | 2.4 mm/m at 100ºC temperature difference | ||||||

| Core | ||||||||

| Aluminium foils from AIMn alloys (EN AW-3003) Bare comprehensive strength | [N/mm²] | > 2.5 | ||||||

| Weight | [kg/m³] | > 50 | ||||||

| Surface | ||||||||

| Lacquering | Coil Coating Fluorocarbon based (e.g. PVDF) | |||||||

| Gloss (initial value) | [%] | 25-40 | ||||||

| Pencil Hardness | HB-F | |||||||

| Acoustical Properties | ||||||||

| Sound Absorption Factor | α s | 0.05 | ||||||

| Airborne sound insulation index (acc. to ISO 717-1, ISO 140-3) | R w | [dB] | 21 | 21 | 22 | 23 | 25 | |

| Thermal Properties | ||||||||

| Termal conductivity (regarding total thickness, incl. cover sheets) | λ | [W/mK] | 0.95 | 1.35 | 1.78 | 2.25 | 2.70 | |

| Thermal resistance | R | [m²K/W] | 0.0063 | 0.0074 | 0.0084 | 0.0089 | 0.0093 | |

| Temperature Resistance | [ºC] | -40 to +80 | ||||||

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process..

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Aluminum sheets have multiple uses in decoration and architecture. This versatile material can be easily shaped and molded into various forms, making it perfect for a wide range of architectural projects. It is commonly utilized in exterior cladding, roofing, window frames, and facades, lending a sleek and contemporary appearance to buildings. Moreover, aluminum sheets are also employed for decorative purposes like wall panels, art installations, signage, and furniture. Architects and designers often choose aluminum due to its lightweight and durable properties, enabling them to create visually appealing and functional structures. Additionally, aluminum's resistance to corrosion makes it suitable for both indoor and outdoor applications.

- Q: Are aluminum sheets suitable for interior design applications?

- Aluminum sheets are an excellent choice for interior design purposes. This material is both versatile and durable, allowing for various creative uses in enhancing the aesthetics of indoor spaces. Its malleability enables easy shaping, cutting, and manipulation, resulting in unique and contemporary designs. Different finishes, such as brushed, polished, or textured, further expand the design options. One major advantage of utilizing aluminum sheets in interior design is their lightweight composition. This feature simplifies handling and installation, reducing labor and transportation expenses. Additionally, aluminum's corrosion resistance makes it perfect for environments with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets find application in various aspects of interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. The ability to paint or coat them in different colors allows seamless integration into any design scheme. Furthermore, perforation or engraving can create patterns or intricate designs, adding a distinct visual appeal to the space. Moreover, aluminum is a sustainable material with high recyclability. The recycling process consumes significantly less energy compared to the production of new aluminum, making it an environmentally friendly option for interior design applications. To summarize, the versatility, durability, lightweight nature, corrosion resistance, and manipulability of aluminum sheets make them highly suitable for interior design. They offer numerous design possibilities and can be used in various applications, rendering them a popular choice among designers and architects.

- Q: I have heard that consuming aluminum can increase your risk for Alzheimer's later in life.Knowing this, would it increase my risk to eat sweet potatoes cooked in aluminum foil?Even if there is a negligible risk, I still want to know for curiosity reasons.Thank You

- You are not eating the aluminum foil when wrap food in it to cook. There is little transference of aluminum to the food you eat. When using it for baked potatoes, the skins just slide off so the potato meat itself had not contact with the foil. Though I have also read something on the use of aluminum cooking vessels and aluminum foil having some properties that can be dangerous to our health, I could find no articles from the FDA or other such qualified organizations regarding the use of aluminum foil.

- Q: How much is one ton of aluminium plate?

- Look at the material of the aluminum sheet about 18 better T6, about 20 to almost 5052 in 25 some brands will be more expensive to buy and then also need to invoice invoice must the seller will give you points plus tax needed to contact

- Q: Are aluminum sheets suitable for food-grade applications?

- Yes, aluminum sheets are suitable for food-grade applications. Aluminum is a widely used material in the food industry due to its excellent properties. It is non-toxic, corrosion-resistant, and has a high thermal conductivity, making it a suitable choice for food processing and packaging. Aluminum sheets can be used to make food-grade containers, trays, and packaging materials. They are also commonly used for cooking utensils, such as baking sheets and foil, which are safe to use in direct contact with food. Additionally, aluminum sheets can be easily cleaned and sanitized, making them a hygienic choice for food-grade applications.

- Q: What are the different methods of surface preparation for aluminum sheets?

- There are several methods of surface preparation that can be used for aluminum sheets. These methods are designed to clean, treat, and prepare the surface of the aluminum to ensure optimal adhesion and paint durability. Here are some of the different methods of surface preparation for aluminum sheets: 1. Mechanical Abrasion: This method involves using abrasive materials such as sandpaper, wire brushes, or sandblasting to physically remove any dirt, rust, or oxidation from the surface of the aluminum. Mechanical abrasion creates a rough texture on the surface, which promotes paint adhesion. 2. Chemical Cleaning: Chemical cleaning involves using acidic or alkaline solutions to remove any contaminants or oxidation from the surface of the aluminum. This method is particularly effective for removing tough stains, oils, or greases. The surface is typically rinsed thoroughly after chemical cleaning to remove any residue. 3. Etching: Etching is a process that involves applying an acidic or alkaline solution to the aluminum surface to create a microscopically rough texture. This rough surface enhances paint adhesion and provides a better bonding surface for coatings. Etching is commonly used as a pre-treatment before applying a primer or paint. 4. Conversion Coating: Conversion coating is a surface treatment method that involves applying a chemical solution to the aluminum surface to create a thin, protective layer. This layer not only improves paint adhesion but also provides corrosion resistance. Common conversion coatings for aluminum include chromate conversion coatings and phosphoric acid anodizing. 5. Mechanical Cleaning: Mechanical cleaning involves using mechanical methods such as brushing, scraping, or buffing to remove loose particles, dirt, or debris from the surface of the aluminum. This method is often used as a preliminary step before applying other surface treatments or coatings. It is important to note that the choice of surface preparation method may vary depending on the specific requirements of the aluminum sheet's application, the condition of the surface, and the desired finish. Proper surface preparation is crucial to ensure the longevity and performance of the paint or coating applied to aluminum sheets.

- Q: Can aluminum sheets be used for interior design purposes?

- Yes, aluminum sheets can be used for interior design purposes. They are versatile, lightweight, and durable materials that can be used for various applications such as wall cladding, ceilings, countertops, backsplashes, and decorative accents. Aluminum sheets offer a modern and sleek aesthetic, and their availability in different finishes and colors allows for customization to fit various design styles and preferences.

- Q: How do I clean and maintain aluminum sheets?

- To clean and maintain aluminum sheets, start by wiping them down with a soft cloth or sponge and a mild detergent or soap. Rinse the sheets thoroughly with clean water and dry them with a clean towel. Avoid using abrasive cleaners or scrub brushes as they can scratch the surface. To maintain the shine and prevent corrosion, you can apply a thin layer of aluminum polish or wax using a clean cloth. Regularly inspect the sheets for any signs of damage or oxidation, and address them promptly to ensure their longevity.

- Q: Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it ideal for various automotive components. It is commonly used in the construction of car bodies, engine parts, wheels, and other structural components. Aluminum sheets offer excellent strength-to-weight ratio, which helps improve fuel efficiency and overall performance of vehicles. Additionally, aluminum has good thermal conductivity, allowing for effective heat dissipation in automotive applications. Overall, the use of aluminum sheets in automotive manufacturing has become increasingly popular due to its numerous advantages.

- Q: What is the weight per square foot of 101 aluminum sheets?

- The weight per square foot of 101 aluminum sheets varies depending on the thickness of the sheets. Please provide the thickness of the aluminum sheets to determine the weight per square foot accurately.

Send your message to us

Competitive Price Aluminum Honeycomb Sheets of Aluminum Siding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords