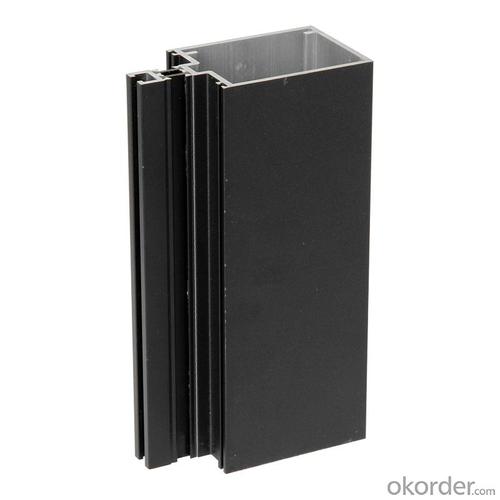

Aluminum Glazing Profiles for Window and Door Aluminium Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium profile

1) Alloy: AA6061, AA6063

2) Temper: T5, T6

3) Series of surface treament:

1. Mill Finished

2. Anodizing: Silver, champagne, light bronze, dark bronze, black, light titanium, dark titanium.

3. Electrophoretic Coating: Silver, champagne, bronze, black, light bronze, dark bronze.

4. Electrostatic Color Powder Coating: Normal color, special color.

5. Fluorocarbon Powder Spraying: Normal color, special color.

6. Wood Grain Coating: Import paper, domestic paper.

- Q: What are the different fastening options available for aluminum profiles?

- There are several different fastening options available for aluminum profiles, depending on the specific application and desired functionality. Some common fastening options include: 1. Screws: Using screws is a widely used method to fasten aluminum profiles. They can be easily installed and provide a strong and secure connection. Self-tapping screws are often used, as they create their own threads in the aluminum profile. 2. Bolts and nuts: Bolts and nuts offer another reliable fastening option for aluminum profiles. They provide a strong connection and can be easily tightened or loosened as needed. It is important to select the appropriate bolt and nut size and ensure proper tightening to prevent stripping or loosening of the connection. 3. T-slot nuts: T-slot nuts are designed specifically for T-slot aluminum profiles, which have a groove along the length of the profile. T-slot nuts slide into the groove and can be easily positioned and tightened using a hex key. They provide a versatile and adjustable fastening option, allowing for easy repositioning or modification of the profile. 4. Clamps: Clamps are commonly used to secure aluminum profiles together or attach other components to the profile. They come in various designs, such as corner clamps or angle clamps, and provide a quick and easy way to assemble or disassemble aluminum structures. 5. Adhesives: Adhesives can be used to bond aluminum profiles together, offering a clean and seamless appearance. However, the strength of the bond may vary depending on the adhesive used and the surface preparation. It is essential to select an adhesive specifically designed for aluminum and follow the manufacturer's instructions for proper application. 6. Welding: Welding is a permanent fastening option for aluminum profiles. It involves melting the aluminum material and fusing it together, creating a strong and durable connection. However, welding requires specialized equipment and skills, making it a more complex and time-consuming process. It is important to consider the specific requirements of the application, such as load-bearing capacity, adjustability, or disassembly needs, when choosing the appropriate fastening option for aluminum profiles. Consulting with experts or manufacturers can help in selecting the most suitable fastening method for a particular project.

- Q: What are the surface hardness properties of aluminum profiles?

- The surface hardness properties of aluminum profiles vary depending on the specific alloy and treatment. Generally, aluminum profiles have a moderate to high surface hardness, making them resistant to scratches and wear. However, compared to other metals like steel, aluminum has relatively lower hardness. To enhance the hardness, surface treatments such as anodizing or hard coat finishing can be applied, which significantly improve the wear resistance and durability of aluminum profiles.

- Q: This question asks for an overview of the various types of adhesives that are compatible with aluminum profiles.

- <p>Aluminum profiles can be bonded with several types of adhesives, each offering unique properties for different applications. Epoxy adhesives are strong and durable, suitable for high-strength bonding. Cyanoacrylate (super glue) offers fast bonding with good strength and is easy to use. Silicone adhesives are flexible and weather-resistant, making them ideal for outdoor applications. Polyurethane adhesives provide strong bonds with excellent flexibility and are resistant to moisture and chemicals. Acrylic adhesives are known for their versatility and strong bonds, while anaerobic adhesives cure in the absence of air and are often used for threaded fasteners. Each adhesive type has specific curing times and temperature resistance, so the choice depends on the specific requirements of the project.</p>

- Q: Are aluminum profiles suitable for transportation equipment?

- Yes, aluminum profiles are highly suitable for transportation equipment. Aluminum is lightweight, which helps reduce the overall weight of the equipment, making it more fuel-efficient. Additionally, aluminum is corrosion-resistant, durable, and easily customizable, making it ideal for various transportation applications such as aerospace, automotive, and marine industries.

- Q: Can aluminum profiles be anodized for improved corrosion resistance?

- Yes, aluminum profiles can be anodized to enhance their corrosion resistance. Anodizing creates a protective oxide layer on the surface of the aluminum, making it more resistant to corrosion and increasing its durability.

- Q: This question asks for a comparison between aluminum profiles and other materials regarding their visual appeal and aesthetic qualities.

- <p>Aluminum profiles are often favored for their sleek, modern appearance and high aesthetic value. They offer a clean, silvery finish that can be anodized or painted to match various design schemes. Compared to materials like wood, they provide a contemporary look, while their uniformity and precision in manufacturing can surpass the natural variations found in wood. When compared to plastics, aluminum profiles offer a more premium feel and are often perceived as more durable and high-quality. Additionally, aluminum's recyclability and low maintenance requirements contribute to its eco-friendly and aesthetic appeal in sustainable design.</p>

- Q: Are aluminum profiles suitable for use in transportation vehicle bodies?

- Yes, aluminum profiles are suitable for use in transportation vehicle bodies. Aluminum is lightweight, corrosion-resistant, and durable, making it an ideal material for reducing vehicle weight and improving fuel efficiency. Additionally, aluminum profiles can be easily shaped and formed to meet specific design requirements, offering versatility in vehicle manufacturing.

- Q: What are the potential health risks associated with handling aluminum profiles?

- <p>Working with aluminum profiles generally does not pose significant health concerns under normal conditions. However, there are a few considerations. Inhalation of aluminum dust can cause respiratory issues, and prolonged exposure may lead to a condition known as 'aluminum dust disease.' Additionally, aluminum can cause skin irritation in some individuals, especially with prolonged contact. It's important to use proper personal protective equipment (PPE), such as masks and gloves, to minimize these risks. Ingestion of aluminum is also a concern, as it can lead to health problems if it enters the body through contaminated food or water, although this is not directly related to handling aluminum profiles.</p>

- Q: What are the anti-static properties of aluminum profiles?

- The anti-static properties of aluminum profiles refer to their ability to prevent or dissipate static electricity buildup. Aluminum is a conductive material, allowing it to quickly discharge any static electricity that may accumulate on its surface. This property helps to prevent the buildup of electrostatic charges, which can be harmful to electronic components or cause problems in sensitive environments such as cleanrooms or manufacturing facilities.

- Q: This question asks whether aluminum profiles can be recycled and if so, the process involved in recycling them.

- <p>Yes, aluminum profiles can be recycled. The recycling process typically involves collection, sorting, and shredding the aluminum profiles. After shredding, the material is melted in a furnace, which separates impurities and leaves behind pure aluminum. This molten aluminum can then be cast into new profiles or other products. The recycling of aluminum is energy-efficient and environmentally friendly, as it requires only 5% of the energy needed to produce aluminum from raw materials. This makes aluminum recycling a sustainable practice that helps conserve resources and reduce waste.</p>

Send your message to us

Aluminum Glazing Profiles for Window and Door Aluminium Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords