Aluminum Furring Strips - PE/PVDF Coated Aluminum Sheet and Coil Coloring Aluminum Green

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior:General sea water-related service...

(2).Certain structural retrofit building applications...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

All four trihalides are well known. Unlike the structures of the three heavier trihalides, aluminium fluoride (AlF3) features six-coordinate Al. The octahedral coordination environment for AlF3 is related to the compactness of fluoride ion, six of which can fit around the small Al3+ center. AlF3 sublimes (with cracking) at 1,291 °C (2,356 °F). With heavier halides, the coordination numbers are lower. The other trihalides are dimeric or polymeric with tetrahedral Al centers. These materials are prepared by treating aluminium metal with the halogen, although other methods exist. Acidification of the oxides or hydroxides affords hydrates.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

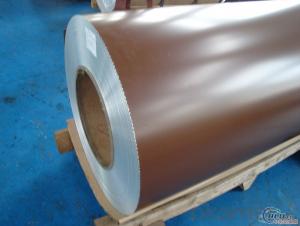

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What is the relationship between the aluminum plate, the aluminum foil and the aluminum alloy strip?

- The concept of aluminum foil and above is the same, but the thickness is not the same, generally considered to be the same product, but the technical requirements of the difference between the two big, divided into two products.

- Q: What are the potential dangers or issues that could arise from using nails or screws to attach aluminum strips?

- <p>There are several risks involved with using nails or screws to install aluminum strips. These include damaging the aluminum strip by causing dents or cracks, especially if the material is thin. There's also the risk of stripping the screw hole, which can weaken the hold and cause the strip to come loose. Additionally, if the aluminum strip is not properly secured, it may lead to accidents or injuries due to falling or improper installation. Using the wrong type of fastener can also lead to corrosion or other material compatibility issues. It's crucial to use the appropriate tools and techniques to minimize these risks.</p>

- Q: This question asks about the environmental effects of utilizing products made from recycled aluminum.

- <p>Using recycled aluminum products has several positive environmental impacts. It conserves natural resources by reducing the need for mining new aluminum, which is energy-intensive and can lead to habitat destruction. Recycling aluminum uses only 5% of the energy required to produce aluminum from raw materials, significantly reducing greenhouse gas emissions. Additionally, it decreases waste in landfills, as aluminum is infinitely recyclable without losing quality. This process also reduces water pollution and soil degradation associated with mining activities. Overall, the use of recycled aluminum products contributes to a more sustainable and environmentally friendly economy.</p>

- Q: Is it possible to utilize recycled aluminum for the production of roofing materials for residential use?

- <p>Yes, you can use recycled aluminum to make roofing materials for your home. Recycled aluminum is not only environmentally friendly but also cost-effective. It maintains the same properties as new aluminum, making it suitable for various applications, including roofing. Recycled aluminum roofing materials are durable, lightweight, and resistant to corrosion, which are desirable qualities for any roofing system. However, it's important to ensure that the recycled aluminum is sourced from a reputable supplier to guarantee quality and safety.</p>

- Q: What is the ease of bending aluminum strips and what factors might affect this?

- <p>Aluminum strips can be bent relatively easily due to their malleability. The ease of bending depends on the alloy type, thickness, and temperature. Pure aluminum is softer and more ductile, making it easier to bend than aluminum alloys. Thinner strips are also easier to bend than thicker ones. Heating aluminum can increase its ductility, making it easier to bend without breaking. However, excessive force or improper bending can cause the strip to crack or deform.</p>

- Q: Explain the distinction between aluminum foil and aluminum strips, including their typical uses and characteristics.

- <p>Aluminum foil and aluminum strips are both made from aluminum but differ in thickness and application. Aluminum foil is very thin and flexible, typically used for food packaging, cooking, and insulation due to its light weight and barrier properties. It is often found in kitchens for wrapping food or lining baking sheets. Aluminum strips, on the other hand, are thicker and more rigid, used for structural purposes, such as in construction, automotive parts, or electrical components. They are also used in manufacturing for creating more durable and robust products. The thickness and flexibility of aluminum strips make them suitable for applications requiring strength and shape retention.</p>

- Q: Is it possible to use aluminum foil as a material for roofing purposes?

- <p>While aluminum foil itself is not a suitable roofing material due to its lack of durability and structural strength, it can be used as a temporary solution in emergency situations or for small repairs. Aluminum foil is not designed to withstand the elements over time, nor does it provide the necessary insulation or protection against water and wind that a proper roofing material should. For long-term roofing solutions, it's best to use materials specifically designed for roofing, such as asphalt shingles, metal sheets, or tiles, which offer greater durability and weather resistance.</p>

- Q: This question asks for criteria to determine if an aluminum strip is still safe and effective for use.

- <p>To determine if your existing aluminum strip is still suitable for use, you should check for any visible signs of damage such as cracks, bends, or corrosion. Ensure that the strip is clean and free from any contaminants that might affect its performance. If the strip is part of a mechanical system, check its dimensions to ensure it hasn't warped or lost its shape. Additionally, consider the strip's age and the conditions it has been subjected to, as prolonged exposure to certain elements can degrade its properties. If you're unsure, consult the manufacturer's guidelines or have a professional assess the strip's integrity.</p>

- Q: Is it possible to utilize recycled aluminum to fabricate new aluminum strips?

- <p>Yes, recycled aluminum can be used to make new aluminum strips. Recycling aluminum is an efficient process that conserves energy and resources. The recycled aluminum is melted down and then reformed into new shapes, including strips. This process is not only environmentally friendly but also cost-effective, as it requires less energy compared to producing aluminum from raw materials. The recycled aluminum strips maintain the same properties as those made from new aluminum, making them suitable for various applications.</p>

- Q: The user is asking if it's possible to use aluminum strips for constructing carports or garages.

- <p>Yes, aluminum strips can be used for carports or garages. They are lightweight, durable, and resistant to corrosion, making them a popular choice for outdoor structures. However, it's important to ensure that the aluminum is of sufficient gauge to support the weight and withstand environmental conditions. Additionally, proper design and engineering are crucial to ensure the structure's stability and longevity. Always consult with a professional to determine the best materials and construction methods for your specific needs.</p>

Send your message to us

Aluminum Furring Strips - PE/PVDF Coated Aluminum Sheet and Coil Coloring Aluminum Green

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords