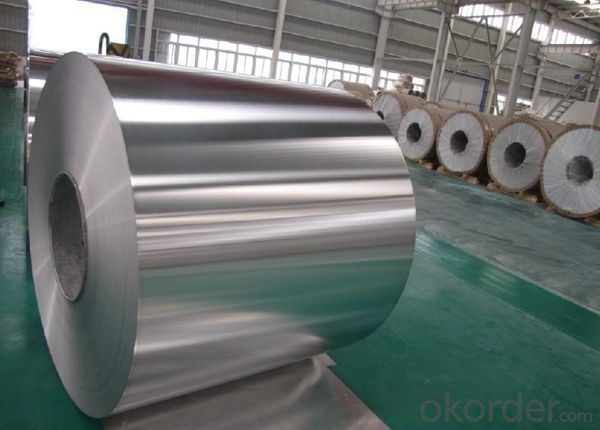

24 Inch Aluminum Foil - Aluminum Foil-Paper Aluminium from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Why you choose us?

Our quelity and service is best in China!

2.Specification and Application

ALUMINIUM FOIL

ALLOY:AA1***

AA3***

AA8***

TEMPER: O H14 H16 H18 H22 H24 H26

THICKNESS: 0.006MM-0.20MM

WIDTH: 200MM-1600MM

COATING: HSL/PRIMER

STANDAR: GB/T 3198-2003

LIGHT GAUGE ALUMINUM FOIL

application:cigarette package, aseptic package, pouches, sachets

alloy:1235/8011/8079

temper:O

thickness&tolerance:0.006mm-0.009mm (±6%)

width&tolerance: 200mm-1650mm (±1mm)

mehanical properties: tensile strength (U.T.S)≥40Mpa, elongation≥1%

standard: GB/T3198 / ASTM-B209 /EN 546

3.Pictures

4.FAQ

1)How about our payment term?

LC and TT and other.

2)Which country can we supply?

All around the world!

Production Flow of Hot Rolled Checkered Steel Plate:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

- Q: A factory has a machine shop in which three machines (A, B and C) produce 100cm aluminum tubesAn inspector is equally likely to sample tubes from A and B, and three times as likely to select tubes from C as he is from BThe defective rates from the three machines are: A: 10%B: 10%C: 20%What is the probability that a tube selected by the inspector:(i)is from machine A;(ii)is defective;(iii)comes from machine A, given that it is defective.

- Put the ice cube in hot salt waterAnd then put the ice cube in extremely cold water, and that should keep it from melting for a whileHope I helped!

- Q: i'm sorry, i have ask this before, but in different categories.I still want to collect some of your idea PMe my group need to prepare for 2 presentations about physic.I still confused about the topics for both categories.1) Electric Magnet2) Wave (sound, light, especially electromagnetic)anyone will help me out from my problem?thanks a lot! D

- I think it might be a bit brittle and could break from metal fatigue.

- Q: I just learned how I can season beef patties, stack them between wax paper and freeze themBut how long can I keep them frozen before they start to go bad?

- The main factor here is what type of wrap are you using? It's fine to separate them before freezing, but then you need a good moisture resistant covering.The meat will last for up to a year if you keep out moisture and etcI do a lot of home freezing and have found that plastic bags and so called freezer bags are not worth a flipWalMart, and some grocers sell the large rolls of white freezer paper -it comes in rolls like aluminum foils and waxed paper, and is found usually right beside themI wrap meats in the white paper, securing it good, then tape with freezer tapeThis way, I have a nice flat surface on which to write the contents and date the packageNever a problemThe bags will sometimes come loose and you end up with freezer burn-not good, as you have to discard the food.

- Q: I have extremely dry hair, especially on the inner hairIt's very noticeable and looks damagedI rarely use heating product on my hair, I shampoo every other day and I use biosilk but it still looks crappyI know it's caused by a medical condition but the doctors cant do anything about my hairWhat can I use?

- Perfectly safe to use aluminum foil in the oven.NOT so much in the microwave, lol:)

- Q: HeyI have a macbook aluminum and I wanna try to keep my battery from wearing out as much as I canI know it will eventually wear out but I have been reading about how to make your battery last longer and something I heard is that if you keep your laptop plugged in the outlet after it is completed charged it will help because it will use the power from the outlet instead of out of the battery so it will help a bit So my question is does it really help if I leave my laptop plugged in after it has charged completly!??

- open the trunck and look at the cylinder from the backSee if there is a U shaped clampremove that and the cylinder will drop out

- Q: i bought a turkey and its already fixed and everything but do i put it in the oven with aluminum foil or not? .i don't know how to cook yet.so i don't want to burn down the house

- I would say a Yorkshire Terrier(Yorkie)They're actually pretty smart, and fairly easy to housebreakChihuahuas are also good, but some can become aggressive(not with you, but strangers or other dogs)Really, though, I suggest getting a dog from a shelterOver 2mildogs are killed a day in sheltersYou can find Yorkies there, though, if you look hard enoughI hope I helpedGood luck with your new dog, whichever one you getEDIT: Whoops, you said a PomMy answer is still the same, thoughPom's can be mean, tooAll toy breeds can, but I think Yorkies a little more sweet when socialized.

- Q: i know its good for my world history class researc paper because it concerns our future, but i am asked to bring a poster about it and a 3-d visuali know what to do for the poster (like a graph or cycle) but how can i represent my essay with a 3-d visual about the gren house effect or global warming.

- no but you will develop Alzheimer later on in life from eating foil

- Q: Just curious, having a party soon and needed some opinionsThanks for your answers.

- Mussels vinaigrette 2 lbs mussels 1/2 C olive oil 3 T red wine vinegar 2 tspDijon mustard 2 shallots, finely chopped 3 T parsley, finely chopped 2 T capers salt and pepper to taste lettuce leaves for garnish (I like to use butter lettuce) Serves 4 to 6 as an appetizer After cleaning mussels, place in a large pot with a tightly fitting lid and do not add any liquid or seasoningCover the pot and cook over high heat for 5 to 6 minutes, shaking the pot occasionallyRemove from the heat and allow to cool enough for you to handle the musselsRemove the from the shells, and discard the shells as well as any mussels that did not open Whisk together the oil, vinegar, mustard, salt, and pepperAdd the mussels and the remaining ingredients, stirring gently to combineRefrigerate for at least 1 hour, or until ready to serveServe on a bed of lettuce leaves, garnish with additional parsley and lemon slicesEnjoy!

- Q: After cooking meat on my new Nordic Ware flat top reversable grill/griddle, it leaves a black residue which has me scrubbing for 20 minutes even after soaking! When I looked up best ways to clean cast aluminum on the web, it said to use steel wool or a kitchen cleanerHowever, that advice is contrary to the cleaning directions on the box which advises against itWhat do you suggest?

- He plays a fender jaguarHe really likes the fender line-ups.

- Q: well, today i skipped lunch because i decided to work on some homework instead, so i had left my turkey and cheese sandwhich with mayonaise in my lockerI already left school and i just remeberedThe sandwhich has been there since 7:20 this morning, if i get to it by 7:20 tomorrow morning do you think it would have already started to smell bad enough for other people to smell through my locker? It's just that it's happened to me once before and it was really embarassing and i'm afraid it;; happen again(the sandwhich is rapped in aluminum foil and in a brown paper bag) thank you!

- You don't mention what climate you are in, so I will assume an average building temperature of about 72 degrees.you should be able to dispose of it with no problem if you do it early, don't open it at all and just act naturalThe mayo will be beyond it, thoughI once left pastrami on rye tightly wrapped in a bag in a bank vault from Friday evening to Monday morning.it wasn't very bad, but I also kept all the others out until I did the removalI still regret the loss of that sandwich.

Send your message to us

24 Inch Aluminum Foil - Aluminum Foil-Paper Aluminium from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords