Aluminum Foil with PET and LLDPE for Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

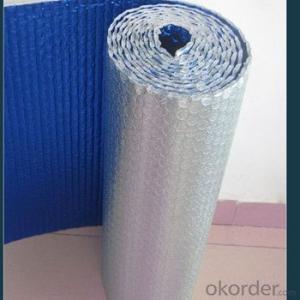

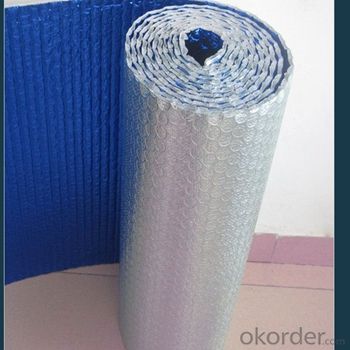

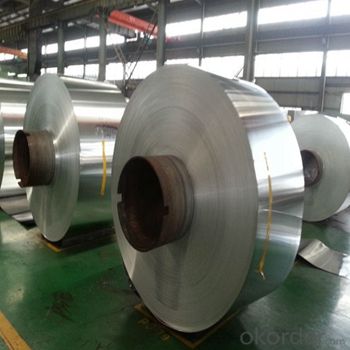

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: What kind of protective film for desktop LCD monitor?

- By the way, it's better to use a PET LCD monitor to protect the film, which is better than other materials. The protective film about card brand is also good, introduce you, hope to solve your problem.

- Q: How to remove the protective film on elevator?

- Do NOT use electric hair drier! It will make it more difficult to remove! Is the elevator made of stainless steel? If it is, you'd better find someone professional in this field to help you remove the film! They have their ways! It will make more difficult to remove.

- Q: How to distinguish the adhesion degrees of Protective film materials?

- It depends on what exact kind of product the customer want. Certain product has certain function and degree of adhesion. 1N or less refers to low degree of adhesion; 1-3N refers to medium degree, and 3N or more, high degree. In addition, there are also slight degree and super degree somewhere.

- Q: PVC protective film reacted with the plastic on which it's coated. Why did that happen?

- It's about the glue.

- Q: Performance index of PE protective film

- 2. low viscosity protective filmCharacteristics: thick (0.03m + 0.003), width (less than 1.3), high (100-1000), substrate (PE), peel strength (10-20g/cm), temperature (60), stretching rate (>400)Purpose: tack stability, good adhesion, then peeling performance is good, no glue residue phenomenon for steel mirror plate, titanium plate, smooth plastic, silk screen, Ming brand and so on.3. medium and low viscosity protective filmCharacteristics: thick (0.03m + 0.003), width (less than 1.3), high (100-1000), substrate (PE), peel strength (30-50g/cm), temperature (60), stretching rate (>400)Purpose: tack stability, good adhesion, then peeling performance is good, no glue residue phenomenon for furniture Polaroid plate, stainless steel plate, ceramic tile, marble, artificial stone and so on.

- Q: How to easily remove the protective film of the new refrigerator?

- Question: tape that protective film to tear it? Answer: tore it, so that you can make the refrigerator sealing better, ask: "your home torn? My home is mainly a child, I'm afraid she drew it!" answered: tore.

- Q: What are the differences between PE release film and PE protective film?

- The adhesives used in PE release films are release agents which the property that make it impossible to stick sticky objects to it. It's mainly used on the separation of double-sided adhesive tapes and that of label and its backing paper. The adhesive used in PE protective films is glue of low adhesion which makes the film adhesive though not very sticky. And the film is used on surface protection of materials.

- Q: There are two screens in the computer screen. One side says "A", and the other is "B". Do you need to paste A first and then paste B? Do you have two at a time? Thank you

- You can see the following steps.1. will be marked with a membrane facing the quasi screen, and will be removed from the layer of film labels pulled, and slowly tear the part of the layer, please pay attention to fingers do not touch the protective film adsorption layer (middle layer)

- Q: High transmittance screen protection film, compared to the conventional screen protection film, more than HC hardness treatment, how can I do hardness treatment to achieve high transmittance?

- Toughened glass filmTempered glass (Temperedglass/Reinforcedglass) belongs to safety glass. Glass has a fairly good abrasion resistance and is very hard, with a Vivtorinox hardness of 622 to 701. Toughened glass is a kind of prestressed glass, in order to improve the strength of the glass, the methods commonly used in chemistry or physics, formed on the surface of glass glass under compressive stress, first offset surface stress force, so as to improve the bearing capacity of reinforced glass, its wind, cold, impact etc.. The toughened glass protective film is the highest security level for mobile phone screen protection.

- Q: What harm can the protective film on bottled water do?

- It's not harmful. It's separated from the water bottle. And there are national security standards to keep it under control.

Send your message to us

Aluminum Foil with PET and LLDPE for Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords