Aluminum Foil Battery for Pharmaceutical Blister Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description

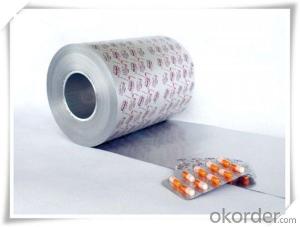

Aluminum foil is widely used in medicine or pharmaceutical packaging, especially for Asian market. Because the good anti heat and anti wet specification, it's very good for packaging tablets and food. Noramlly for medicine packging, the quality should be higher than food packaging. For blister packaging, we usually use direct casting quality, and the popular alloy is 8011 with hard temper.

2.Specification and Application

Specification

| Alloy | 8011 |

| Temper | hard |

| Process | DC / CC |

| Thickness | 20mic~30mic |

| Width | 400mm~1500mm |

| Core ID | 76mm / 152mm |

Chemical Composition

| Alolly 8011 | % Maximum |

| Si | 0.05~0.13 |

| Fe | 0.7~1.3 |

| Cu | 0.05 |

| Mn | 0.02 |

| Mg | - |

| Cr | - |

| Ni | - |

| Zn | 0.1 |

| Ti | 0.02 |

| Zr | - |

| Others | 0.15 |

Property

| Tensile strength | 150~200Mpa |

| Elongation | 0.5%~3% |

| Bursting | / |

3. Advantages

We've been specialized in aluminium foil for more than ten years, we know this product very well, and we have good finacial support from government. Meanwhile, we can offer both DC and CC quality with this kind of 8011.

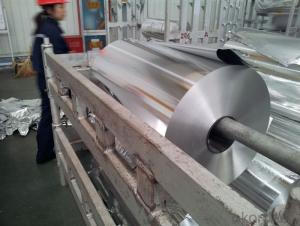

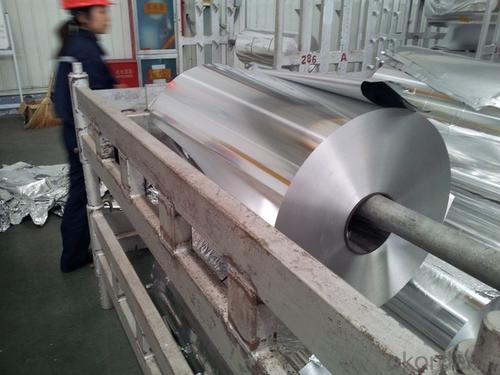

4. Pictures

5. FAQ

What is your Production?

Our regular production time is over 30~40 days, if it's regular size, the time can be shorter.

What is your MOQ?

The MOQ is 3 tons per size.

- Q: What's the price of aluminum foil?

- Different aluminum foil manufacturers, the prices are different, it is recommended to use anychem chemical engine, through comparison to find your satisfied suppliers and reasonable prices!

- Q: I've got my own little set up goingI'm using salt water and a copper wire for the hydrogen side, but an Aluminum wire for the oxygen sideThe reaction went a lot faster then it normally does for me, but the liquid in the jar turned a white cloudy color, like there was something in italso, when I exploded the hydrogen and oxygen (I think, it could have also been chlorine from the NaCl in the water) there was a faded blueish gooey substence on the side of the jarWhat could that be? and what is the white stuff in the water?

- Acid is a slow burn on some metals, aluminum tends to turn black when burned where iron turns red when it rusts or burnsI'd say the hf acid left some slight burn marks on your rails.

- Q: I know they run fine in ex Soviet weapons since they were built for it like AKs and SKSs and stuffButhow about durable non soviet arms? I hear they're bad for AR-15s.

- It will prolong the process

- Q: Ok.here's my pumpkin roll recipe.3 eggs, 1c sugar, 2/3 c pumpkin, 1t lemon juice, 3/4 c flour, 1t ginger, 1t baking powder, 2 t cinnamon, 1/2t nutmeg, 1/2t salt.Beat eggs on high for 5 minutesGradually add other ingredients and mix wellSpread into well greased 15x10x1 panTop with chopped nuts and bake 15 min 375Turn out on flour sack towel, liberally sprinkled with powered sugarRoll up with towelCoolUnroll and spread with cream cheese mixRoll and wrap in foilSo, how do I tweek this to be chocolate?!?! Thanks!!!

- No tweaking hereChocolate Roll - 10 servings 1 cup cake flour or 3/4 cup all-purpose flour 1/4 cup cocoa 1 tspbaking powder 1/4 tspsalt 3 eggs (1/2 to 2/3 cup) 1 cup granulated sugar 1/3 cup water 1 tspvanilla 1 cup whipping cream; sweetened and whipped Confectioners' sugar Heat oven to 375Line jelly-roll pan (15 1/2x 10 1/2x 1) with aluminum foil or waxed paper; greaseStir together flour, cocoa, baking powder and salt; set asideIn small mixer bowl, beat eggs about 5 minutes or until very thick and lemon-coloredPour eggs into larger mixer bowl; gradually beat in granulated sugarOn low speed, blend in water and vanillaGradually add flour mixture, beating just until batter is smoothPour into pan, spreading batter to cornersBake 12-15 minutes or until wooden pick inserted in center comes out cleanLoosen cake from edges of pan; invert on towel sprinkled with confectioners' sugarCarefully remove foil; trim off edges if necessaryWhile hot, roll cake and towel from narrow endCool on wire rackUnroll cake; remove towelSpread whipped cream over cakeRoll up; sprinkle with confectioners' sugar(NOTE: If using self-rising flour, omit baking powder and salt.)

- Q: it looks like this -gt;Do I light the end and just put it on the ground? Or do I put it in a tube and launch it? If so can a water bottle or paper towel tube work okay?

- Use an aluminum can, not a plastic bottle or paper towel tube since those may melt/burnYou can also be more creative and attach small fins onto the bottle rocket to make it more aerodynamic for fun.I used to experiment with them and had lots of launch failures, but had a lot of fun.

- Q: Ok my mom wants to make an Eye round roast but we no longer have a crock pot (we just moved).Is there any other way that we could possibly cook it?Any advice is welcome!Thanks in advance!

- mirrors don't reflect radio waves

- Q: What are the characteristics of high-quality decorative foil is?

- Quality decorative foil by aluminum - plastic composite decorative material in the form of application, the use of aluminum foil good color, light and heat reflectivity Gao properties, mainly used in construction, furniture, decoration and part gift box.

- Q: IT tells me to Write the correctly balanced equation and the type of reaction for each but how would i do it? it asks in word form please help with these im having trouble(Even if u dont know all please answer the ones you can im having trouble leave a brief explanation of how u got the answer unless if its to long then its okay to not explain please help!)1Oxygen gas reacts with solid copper metal to form copper (II) oxide solid.Balanced Equation:Reaction:2Aluminum metal reacts with copper(II) chloride solution and solid copper.Balanced Equation:Reaction:3Hydrogen sulfide gas is bubbled through a solution of iron (III) chloride.Balanced Equation:Reaction:4Magnesium nitride solid is heated until it forms solid magnesium metal and nitrogen gas.Balanced Equation:Reaction:5Aluminum solid reacts with oxygen gas to form aluminum oxide solid.Balanced Equation:Reaction:

- 12 Cu + O2 - 2 CuO (oxidation reaction) 22 Al + 3CuCl2 - 2AlCl3 + 3Cu (displacement reaction) (Actually the AlCl3 will react with water to form hydrated aluminum oxide and HCl) 3Iron is reduced from +3 state to +2 state, forms iron sulfide precipitate, S- oxidized to elemental sulfur: Fe+++ + e- - Fe++ S- - S + 2e- 3H2S + 2FeCl3 + - 2FeS + S + 6HCl Elemental Sulfur is formed as S8, so the actual balanced equation is: 24 H2S + 16 FeCl3 - 16 FeS + S8 + 48 HCl The type of reaction is oxidation-reduction and precipitation since iron sulfide is insoluble42 Mg2N3 - 2 Mg + 3N2 (decomposition reaction) 54 Al + 3O2 - 2 Al2O3 (oxidation reaction)

- Q: give me some other details about it too

- Home center,, has that, used to patch ducts, peal the backing and stick,, Also check the automotive section,

- Q: I'm looking to make sweet corn cake using Marie callendars corn bread mix

- Hard to say, are you replacing existing system? How about duct work? Have you considered mini splits, Do you need a new compressor or air handler? To replace the whole system, I would guess, $3,000Depends, a 2 ton unit should be enoughUsed to be, new system, $1,000 a ton, easyTimes have changed, If I was you,I would leave the window shaker running all day, on thermostat, do not open the windows, cool the house, dry it out, the dry air makes it feel cooler than it is.

Send your message to us

Aluminum Foil Battery for Pharmaceutical Blister Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords