Aluminum Foil Facing Fiberglass Foil Insulation Facing For Rock Wool

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

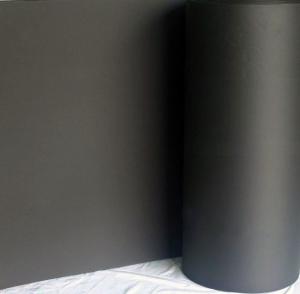

Introduction of Aluminum Foil Facing

Aluminum foil: 7 microns +Flame retardant Adhesive+Glass fiber cloth:8X8 for Fiberglass Foil Facing for Glasswool, Rockwool, Duct Wrap and Roof Insulation

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Aluminum Foil Facing

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Specification of Aluminum Foil Facing

COMPOSITION:

Aluminum foil: 7 microns

Adhesive: Flame retardant

Glass fiber cloth:8X8

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD | |||||

Basic weight | gsm | 140 | ASTM D646 | |||||

Tensile strength: M. D. X. D. | N/25mm | 280 280 | ASTM C1136 | |||||

Burst strength | N | 180 | ASTM D774 | |||||

Reflectivity of foil surface | % | 85 | ---------- | |||||

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

The product is a brand-new environmental friendly thermal insulation material. It made from Aluminum foil and LDPE, processed by special machines. Its heat transfer forms are mainly three types: radiation, conduction, and convection. This new insulation material has not only solved the uncomfortable to the human body and the harm to environment caused by the former glass fiber insulation material and spongy kind insulation material.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

Moreover, it can also keep the ultraviolet radiation out of rooms, which could easily penetrates ordinary thermal insulation material such as the iron sheet, the concretes, the lumber and so on. We researches and develops this product based on the combination polyethylene and aluminum foil which has the characteristic of heat and light reflecting . This bubble laminated aluminum foil insulation material provides excellent isolation, thermal reflection, heat insulation and anti-radiation function. All these functions enable the product can be used in house construction area (roof, wall and floor), so as to reach moisture-proof, heat preservation and energy conservation purpose etc

- Q: What precautions should be taken when handling hot food using aluminum foil as a cooking tool?

- <p>When handling hot food using aluminum foil, first ensure the foil is thick enough to withstand high temperatures without puncturing. Always use heat-resistant gloves or a thick cloth to avoid burns. Do not wrap food directly in aluminum foil if it's very hot, as this can cause the foil to tear or the food to stick. Allow the food to cool slightly before wrapping. When removing the foil from the heat source, use tongs or a spatula to avoid direct contact with the hot foil. Be cautious of steam when opening the foil, as it can be very hot.</p>

- Q: Can aluminum foil be used as a substitute for a pizza stone or baking sheet when making pizza?

- <p>Yes, you can use aluminum foil as a makeshift surface for making pizza if you don't have a pizza stone or baking sheet. However, it may not provide the same even heat distribution or crispiness as a pizza stone. Ensure the foil is heavy-duty to prevent tearing and preheat it with the oven to get a better result. Keep in mind that the foil can reflect heat, which might affect the bottom crust's texture. It's a good alternative, but for consistent quality, using a proper pizza stone or baking sheet is recommended.</p>

- Q: What are the chemical characteristics of the side of aluminum foil that faces outwards?

- <p>The chemical properties of the aluminum foil facing outward are primarily determined by its elemental composition, which is aluminum (Al). Aluminum is a lightweight, soft, and malleable metal with a silvery-white appearance. It is highly reactive and readily forms a thin, protective oxide layer (aluminum oxide) when exposed to air, which prevents further oxidation. This oxide layer is what gives aluminum foil its resistance to corrosion and its shiny appearance. Aluminum is also a good conductor of heat and electricity. The facing side of the aluminum foil may have slight differences in properties due to the manufacturing process, but fundamentally, it remains chemically similar to the rest of the aluminum foil.</p>

- Q: What are the various materials used as facings for aluminum foil, and how do they differ from one another?

- <p>Aluminum foil facing materials are used in construction and insulation to provide a barrier against air and moisture. The different types include: 1) Kraft paper facing, which is a strong, absorbent paper used for general purposes; 2) Glassine facing, a thin, glossy paper with good water resistance; 3) PE-coated facing, where a layer of polyethylene is applied for enhanced water resistance; 4) Aluminum foil facing, which is a thin layer of aluminum for superior barrier properties; 5) Silicone-treated glass fabric, offering high-temperature resistance and used in high-performance applications. Each type has unique properties affecting their use in various applications.</p>

- Q: Is it possible to use materials other than plastic for food wrapping?

- <p>Yes, you can use alternatives to plastic for food wrapping. Materials such as beeswax wraps, silicone sheets, and reusable cotton or linen wraps are eco-friendly options that can be used to cover bowls or wrap food items. These materials are reusable, washable, and can be composted at the end of their life cycle, reducing waste and environmental impact. Additionally, parchment paper and aluminum foil can be used as disposable alternatives, though they are not as sustainable as reusable options.</p>

- Q: Is it possible to recycle aluminum foil facing multiple times? If yes, what is the process involved?

- <p>Yes, aluminum foil facing can be recycled multiple times. The recycling process involves collecting and sorting aluminum waste, which is then shredded or crushed. The material is melted in a furnace at high temperatures, and the molten aluminum is poured into molds to form new products. This process can be repeated indefinitely without losing the quality of the aluminum, making it one of the most recycled materials globally. The recycling of aluminum saves energy and reduces the environmental impact compared to producing aluminum from raw materials.</p>

- Q: Is it possible to use a single piece of aluminum foil for cooking or baking multiple times?

- <p>While aluminum foil is a versatile kitchen tool, it is not recommended to reuse a single piece of aluminum foil for cooking or baking multiple times. Aluminum foil can tear or become thin with use, which may compromise its effectiveness and potentially allow food to stick or contaminate the foil. Additionally, repeated use can lead to the accumulation of food particles and bacteria, posing a risk to food safety. It's best to use a fresh piece of aluminum foil for each cooking or baking session to ensure hygiene and椋熷搧瀹夊叏.</p>

- Q: Is it safe to use the same piece of aluminum foil repeatedly before disposal?

- <p>Reusing aluminum foil is generally not recommended due to hygiene and food safety concerns. Each time you use foil, it can pick up bacteria from food and surfaces, which can multiply with subsequent uses. Additionally, the foil can tear or become thin, potentially allowing harmful substances to leach into your food. For safety, it's best to use a fresh piece of aluminum foil for each use.</p>

- Q: Is it safe and effective to use aluminum foil with a reflective side to wrap vegetables when grilling?

- <p>Yes, you can use aluminum foil facing to wrap vegetables for grilling. Aluminum foil helps to retain moisture and heat, ensuring that the vegetables cook evenly and remain tender. The reflective side of the foil can also help to distribute heat more evenly. However, be cautious not to let the foil touch the flame directly, as it can cause flare-ups. Make sure to poke some holes in the foil to allow steam to escape and prevent the vegetables from becoming too soggy.</p>

- Q: The user wants to know if they can reuse their old aluminum foil facing to create a new one if it gets damaged.

- <p>Yes, you can use your old aluminum foil facing to make a new one if it gets damaged. Simply clean the old foil facing thoroughly, ensuring all adhesive residue is removed. Then, cut a new piece of aluminum foil to the appropriate size and shape. Apply a thin layer of adhesive, such as construction adhesive or double-sided tape, to the back of the new foil. Press it firmly onto the old facing, ensuring a smooth and secure bond. Allow it to dry according to the adhesive's instructions before using. This can be a cost-effective way to extend the life of your foil facing.</p>

Send your message to us

Aluminum Foil Facing Fiberglass Foil Insulation Facing For Rock Wool

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords