Nitrile Rubber Pipe with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Description

rubber plastic is a high quality heat-insulating and heat-preservation material which use butyronitrile rubber and polyvinychloride(NBR,PVC) as main raw materials.

The productionprocess includes mixing, tensing and continuous extruding , heating andfoaming, cooling and cutting.

2.Main Features of Rubber Plastic

-Lower heat-conductivity

-Higher fire-blockingperformance

-Damp-proof andWater-proof

-Softness

-Neat and

-Easy to installeasy handing and storage

-Good flexibilityand tenacity

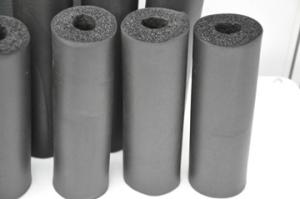

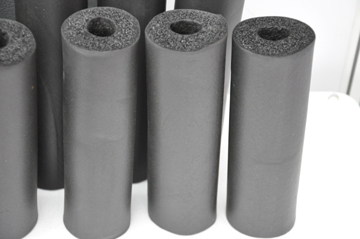

3.Rubber Plastic Images

4.Rubber Plastic Specification

--Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are some suggestions to ensure plastic containers are used in a more hygienic and long-lasting manner?

- <p>To use plastic containers more hygienically and durably, follow these tips: 1) Always wash containers with warm soapy water and rinse thoroughly before and after each use. 2) Avoid putting hot foods or liquids directly into plastic containers to prevent warping and potential chemical leaching. 3) Do not use scratched or damaged containers as they can harbor bacteria and are more likely to break. 4) Store containers in a dry, cool place away from direct sunlight to prevent degradation. 5) Regularly inspect containers for signs of wear and replace them when necessary. 6) Use containers within their recommended temperature range to maintain their integrity and safety.</p>

- Q: This question asks for instructions on how to clean aluminum foil facing after it has been used in cooking or baking.

- <p>To clean aluminum foil facing after use, first let it cool down to avoid burns. Then, gently scrape off any food residue with a spatula or the edge of a knife. For stubborn stains, mix a solution of warm water and dish soap, and wipe the surface with a soft cloth or sponge. Rinse with clean water and dry thoroughly. For baked-on food, you can use a plastic scraper or an old toothbrush to gently remove it. Avoid using abrasive materials that could scratch the surface. Regular cleaning will help maintain the integrity and appearance of your aluminum foil facing.</p>

- Q: This question asks for a comparison of the pros and cons associated with the use of aluminum foil facing in construction or other applications.

- <p>Aluminum foil facing has several advantages, including excellent heat and cold insulation properties, which can significantly improve energy efficiency. It is also lightweight, making it easy to handle and install. The material is resistant to corrosion and has a long lifespan, reducing maintenance and replacement costs. Additionally, it provides a smooth, clean surface that is easy to clean and maintain. However, there are disadvantages such as its high cost compared to some alternatives, which can be a barrier for some projects. It can also be damaged by sharp objects, which may compromise its integrity. Lastly, while it reflects heat, it can also reflect sound, potentially leading to acoustic issues in some environments.</p>

- Q: What distinguishes aluminum foil facing from other types of facing materials?

- <p>Aluminum foil facing is a type of facing material that uses a thin layer of aluminum, known for its excellent barrier properties against air, moisture, and light. This makes it ideal for insulation and packaging applications where preservation of contents is crucial. In contrast, other types of facings, such as paper, fabric, or plastic, may not offer the same level of barrier protection. Paper facings are often used for their aesthetic appeal and are more breathable, while fabric facings provide flexibility and are used for applications requiring durability and comfort. Plastic facings can be waterproof and are used where a shiny or smooth surface is desired. Each type of facing has unique properties that make it suitable for specific applications, with aluminum foil facing being particularly notable for its barrier capabilities.</p>

- Q: This question asks for the steps to prepare aluminum foil for cooking, specifically how to set it up.

- <p>To prepare aluminum foil facing for cooking, first, cut a piece of aluminum foil larger than the cooking surface. Clean the foil to remove any dust or debris. Lightly grease the foil with cooking spray or oil to prevent food from sticking. Fold the edges of the foil up to create a shallow tray, ensuring the sides are high enough to contain any juices. Place the foil on the cooking surface, and you're ready to cook. Always handle the foil with utensils when hot to avoid burns.</p>

- Q: This question asks for a method to clean aluminum foil after cooking to get rid of excess oil.

- <p>To remove excess oil from aluminum foil after cooking, first let the foil cool down to avoid burns. Then, you can use a paper towel or a clean cloth to gently wipe away the oil. For stubborn oil, you can wash the foil with warm soapy water. If you're reusing the foil, make sure it's thoroughly dried before storing to prevent any potential for bacterial growth. Always remember to handle aluminum foil with care as it can be sharp and may tear easily.</p>

- Q: What are the potential health hazards linked to cooking with aluminum foil?

- <p>Cooking with aluminum foil is generally considered safe, but there are some potential health risks. Aluminum can leach into food, especially when it comes into contact with acidic or salty foods at high temperatures. This could lead to increased aluminum intake, which has been linked to neurological disorders like Alzheimer's disease, although more research is needed to establish a definitive link. Additionally, aluminum foil can cause burns or injuries if not handled properly. It's important to use foil responsibly, avoiding direct contact with food when possible, and to follow proper food safety guidelines.</p>

- Q: Is it safe to use aluminum foil facing inside a microwave oven?

- <p>No, it is not safe to use aluminum foil facing in the microwave oven. Aluminum foil can cause sparks and potentially start a fire due to the reflective nature of the metal. It can also damage the oven's interior. Always use microwave-safe materials and avoid metal when cooking in a microwave.</p>

- Q: What are the particular criteria or considerations when choosing aluminum foil facing materials?

- <p>When selecting aluminum foil facing, specific requirements include the foil's thickness, which affects durability and insulation properties; surface finish, which can impact heat reflection and aesthetics; and the type of adhesive used for bonding, which should be resistant to heat and moisture. Additionally, the foil should have good barrier properties to prevent moisture and air infiltration, and it should be compatible with the substrate materials to ensure a strong bond. Compliance with safety and environmental standards is also crucial.</p>

- Q: Is it possible to recycle aluminum foil with a facing layer? If yes, what is the process involved?

- <p>Yes, aluminum foil facing can be recycled. The process typically involves separating the aluminum from the facing material. This is done by specialized recycling facilities that use methods such as shredding, washing, and magnetic separation to remove impurities. The aluminum is then melted down and repurposed into new products. It's important to check local recycling guidelines, as some facilities may not accept foil with a facing layer due to the difficulty in separation or the presence of non-recyclable components.</p>

Send your message to us

Nitrile Rubber Pipe with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords