Aluminum Extrusions Profiles Wholesale - Aluminum Corner Profile Factory Direct from China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

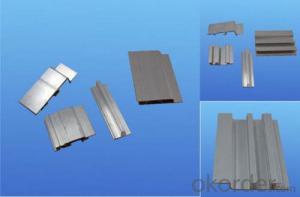

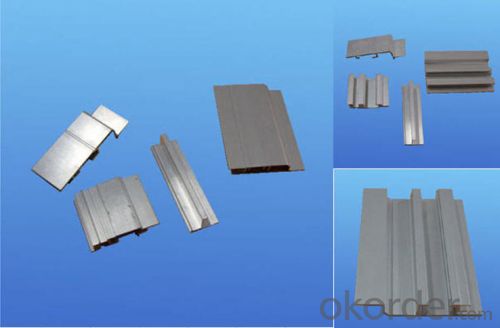

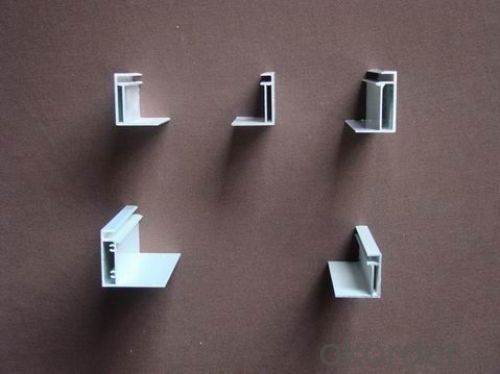

Aluminum Frame and Corner

Products Introduction of Alumium Frame and Corner

Aluminum frame is made from aluminum and minerals. It's raw matrial for window frame, window frame, and other equipment frame. It's easy for construction, cost less, service longer than other materails. The size and design can be customerized.

Advantage of Aluminum Frame and Corner

-Build FLEXIBLE equipment, window, door.

-Bolt your structure together

-Build with Aluminum MORE EASILY

-Aluminum costs LESS

-Service life is more than 10 years

-Can be customerized

Specifications of Aluminum Frame and Corner

(1) Product: Aluminium Frame;

(2) Material: Alloy 6063/6061/6005/6060, T5/T6;

(3) Finish: anodizing, powder coating, wooden, electrophoresis or any color;

(4) Size: customized, same as drawings or samples;

(5) Standard: High-quality;

(6) Characteristics: strong, stylish, durable, corrosion-resistant.

Aluminium Alloy: 6063, 6061, 6005, 6060 Thermal Treatment: T5, T6

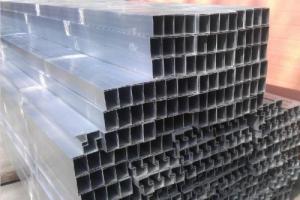

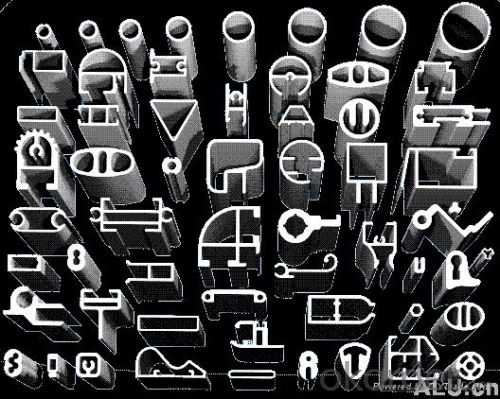

Section Shapes

I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot, and other complicated shapes by custom design.

Surface treating

Mill / Anodizing (oxidation) / Sand blasting / Powder Coating / Electrophoresis / PVDFCoating / Wood effect.

Application of Frame and Corner

1) - for Window and door frames, for Wardrobe cabinet sliding doors, kitchen, for Building curtain glass walls

2) -for Fencing, Rail, Deck and Frame.

3) - for Solar panel frames, solar mounting / roofing brackets

4) - for Industry assembly lines equipment.

5) - for Heatsinks, for LED lighting.

7) - other by custom design size and dimension

FAQ

-What's your company profile?

We CNBM is the largest building material supplier of China. We are Chinese government owned corporation, which takes the 267th place in WOLD FORTUNE 500 CORPORATION. We own the largest prodcution base in North and South of China. With more than 15 warehouses and offices in different countries, our products sell very well all over the world. We have whole quality control system. We'll be your reliable partner.

-Which kind of payment do you usually support?

TT, LC at sight.

-Can you provide samples?

Yes, we provide free of charge samples, you just need to pay for the delivery.

Photos:

- Q: Are aluminum profiles suitable for roofing systems that need to withstand strong wind loads?

- <p>Yes, aluminum profiles can be used for roofing systems that require high levels of wind load resistance. Aluminum is a lightweight yet strong material with excellent resistance to corrosion and weathering. It can be engineered into profiles that provide the necessary structural integrity to withstand high wind loads. The flexibility of aluminum allows for the creation of various shapes and designs that can be tailored to meet specific wind resistance requirements. Additionally, aluminum's durability and low maintenance make it a popular choice for roofing systems in areas prone to high winds.</p>

- Q: How does the aluminum profile bevel come round?

- You can try it yourself and make a small tool to fix this angle in advance.

- Q: What are the different packaging options available for aluminum profiles?

- There are several different packaging options available for aluminum profiles, depending on the specific requirements and preferences of the manufacturers or customers. 1. Bundles: Aluminum profiles can be packaged in bundles, where multiple profiles are stacked together and secured with strapping or shrink wrap. This option is commonly used for larger profiles or when shipping in bulk. 2. Boxes: Smaller aluminum profiles can be packaged in boxes, which provide protection during transportation and storage. The profiles are usually placed in individual compartments within the box to prevent damage from rubbing against each other. 3. Tubes: Some aluminum profiles, especially those with a circular shape, can be packaged in tubes. These tubes are made of durable materials such as cardboard or plastic and provide excellent protection from scratches or dents. 4. Pallets: Aluminum profiles can also be packaged on pallets, especially when shipping in large quantities. The profiles are stacked on top of each other on a pallet and secured with stretch wrap or straps. This option facilitates easy handling and transportation using forklifts or pallet jacks. 5. Customized Packaging: In certain cases, manufacturers or customers may require customized packaging solutions for specific aluminum profiles. This can include foam inserts, protective film, or other specialized packaging materials to ensure maximum protection during transit. It is important to consider factors such as profile size, weight, fragility, and transportation requirements when choosing the appropriate packaging option for aluminum profiles. Additionally, compliance with industry standards and regulations should be taken into account to ensure safe delivery to the end-users.

- Q: This question asks about the various types of aluminum profiles that are utilized in interior design applications.

- <p>Aluminum profiles are widely used in interior design for their strength, durability, and aesthetic appeal. Common types include: 1. Linear Profiles for creating sleek lines in furniture and architectural elements; 2. Structural Profiles for load-bearing structures like beams and columns; 3. Decorative Profiles for ornamental purposes, such as moldings and trims; 4. Frame Profiles for framing pictures, mirrors, and other wall-mounted items; 5. Slatwall Profiles for versatile display systems in retail spaces; 6. Handrail Profiles for stairways and balconies, ensuring safety and style; 7. Window and Door Profiles for modern, lightweight, and energy-efficient applications. Each type is chosen based on the specific design requirements and functional needs of the space.</p>

- Q: How do aluminum profiles contribute to daylighting strategies?

- Aluminum profiles play a significant role in daylighting strategies by facilitating the efficient use of natural light in buildings. These profiles are used to create windows, skylights, and curtain wall systems, which allow for the maximum entry of sunlight into the interior spaces. One of the primary advantages of using aluminum profiles in daylighting strategies is their ability to support large glass panes. Aluminum is lightweight and structurally strong, enabling the creation of expansive glazing systems that maximize the transmission of natural light. These profiles can be designed to have slim sightlines, providing unobstructed views and allowing more sunlight to enter the building. Moreover, aluminum profiles can be thermally broken, meaning they have a layer of insulation between the interior and exterior aluminum sections. This thermal break prevents the transfer of heat and cold, improving the energy efficiency of the building. By minimizing thermal bridging, aluminum profiles contribute to reducing the loss of heat or cool air, resulting in lower energy consumption for heating and cooling systems. Additionally, aluminum profiles can be finished with various coatings that enhance their daylighting performance. For instance, reflective coatings can be applied to the profiles to redirect sunlight deeper into the interior, increasing the overall brightness of the space. Such coatings can also help reduce glare and control the intensity of sunlight, creating a more comfortable and visually pleasing environment. Furthermore, aluminum profiles offer flexibility in terms of design and customization. They can be shaped into different geometries and sizes, enabling architects to create innovative and unique daylighting solutions. For example, the profiles can be curved, angled, or combined with other materials to achieve specific aesthetic and functional requirements. In summary, aluminum profiles contribute to daylighting strategies by allowing for the efficient use of natural light in buildings. Through their structural strength, thermal performance, and customization possibilities, these profiles enable the creation of large glazing systems that maximize the entry of sunlight while maintaining energy efficiency and visual comfort.

- Q: Are aluminum profiles suitable for use in transportation vehicle bodies?

- Transportation vehicle bodies can benefit from the use of aluminum profiles. Aluminum is a material that is both lightweight and durable, making it suitable for this purpose. By utilizing aluminum profiles, vehicles can achieve a reduced weight, resulting in improved fuel efficiency and lower emissions. Furthermore, the excellent strength-to-weight ratio of aluminum profiles enables them to withstand the stresses and loads experienced by transportation vehicles. The corrosion resistance of aluminum is also advantageous, especially for vehicles exposed to harsh environmental conditions. Additionally, the flexibility of aluminum profiles allows for easy formation and shaping into complex designs, providing versatility in vehicle body construction. Overall, the adoption of aluminum profiles in transportation vehicle bodies presents numerous advantages, contributing to its widespread popularity in the industry.

- Q: How do aluminum profiles perform in terms of chemical resistance?

- Aluminum profiles generally have good chemical resistance, although their performance can vary depending on the specific chemicals involved. Aluminum is resistant to a wide range of acids, alkalis, and organic solvents. It also has excellent resistance to atmospheric corrosion, making it suitable for outdoor applications. However, aluminum is not resistant to all chemicals. It can be susceptible to corrosion in the presence of certain chemicals, particularly those with high acidity or alkalinity. Strong acids, such as hydrochloric acid or sulfuric acid, can cause corrosion of aluminum profiles. Similarly, strong alkalis, like sodium hydroxide or potassium hydroxide, can also attack aluminum. In addition to the specific type of chemical, the concentration and temperature of the chemical can also affect the performance of aluminum profiles. Higher concentrations and elevated temperatures can increase the likelihood of corrosion. To enhance the chemical resistance of aluminum profiles, they can be treated with various surface coatings or anodized. These treatments create a protective layer that improves resistance to corrosion caused by chemicals. In conclusion, while aluminum profiles generally have good chemical resistance, it is important to consider the specific chemicals involved, their concentration, and temperature when determining their suitability for a particular application.

- Q: What are the anti-static properties of aluminum profiles?

- Due to their inherent electrical conductivity, aluminum profiles exhibit exceptional anti-static properties. This unique feature enables them to effectively dissipate static charges and prevent the build-up of static electricity. Consequently, aluminum profiles find widespread use in various industries, including electronics, automotive, aerospace, and manufacturing. In these sectors, they serve multiple purposes such as supporting conveyor systems, providing protective enclosures, and serving as grounding components. By minimizing the dangers associated with static electricity, such as electrostatic discharge (ESD) damage, fire risks, and interference with delicate electronic devices, the anti-static qualities of aluminum profiles guarantee safe and dependable operations.

- Q: What is the relationship between aluminum alloy and aluminum alloy?

- First, according to use can be divided into the following categories: 1. building doors and windows, aluminum doors and windows [1] (divided into two windows and curtain walls). Special aluminum radiator 2. CPU radiator 3. Aluminum Alloy shelf aluminum profile, the difference between them is that the different cross-sectional shapes. They are produced by hot melt extrusion 4.. Industrial aluminum: mainly used in automation equipment, sealing cover skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, electronic machinery industry and clean room with the majority!

- Q: Where can I get it, or Jiaozhou, Jiaonan, where there are aluminium profiles? You'd better leave me a call... And do you have any training places for Thai engraving software?.

- What are the disadvantages of using electric bicycle?For chemical two power supply, the charging time is longer, the charge current is smaller, the battery charge discharge cycle is higher, popularly speaking, is the battery life long.What kind of bike is the most labor-saving and fast?Type 700 tires, 27 inch wheel diameter km racing is the best effort, but the strength of car tires will be low, embeds the groove their spokes pierced with two holes, this is a rule, every time just two, not too much; they cannot run on bumpy roads, not equipped with others.There is a price of 600 yuan / vehicle, bearing material difference, the normal price is 3000 yuan / vehicle, at least Taiwan bearings.With Japanese production generally suggest that smuggled in second-hand bicycles, is generally 300 yuan / vehicles to 500 yuan / vehicles, 24 inch, 26 inch, 1 inch and 3/8 section of ordinary tire can, very suitable for long-distance riding, such as send tickets, send pictures, send express salesman, home appliance

Send your message to us

Aluminum Extrusions Profiles Wholesale - Aluminum Corner Profile Factory Direct from China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords