Aluminum Diamond Plate Sheets in Denver - Diamond Embossed Aluminum Sheets 1xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

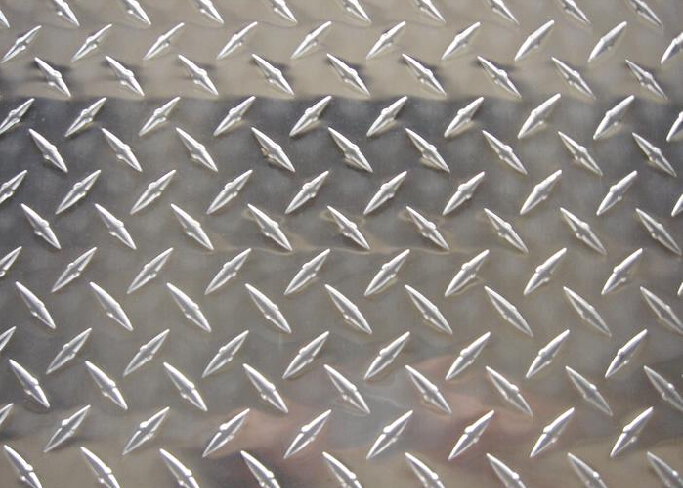

1.Structure of Diamond Embossed Aluminum Sheets 1xxx Description

Diamond Embossed Aluminum Sheets 1xxx has great ductility, heat conductivity, anti-corrosion and moisture resistance properties which are very useful in the field of construction.

Diamond Embossed Aluminum Sheets 1xxx is widely used for decorative purpose in construction, packing and appiance. It is also very commonly used for anti-slippery purpose in vehicles and public places.

2.Main Features of Diamond Embossed Aluminum Sheets 1xxx

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.Diamond Embossed Aluminum Sheets 1xxx Images

4.Diamond Embossed Aluminum Sheets 1xxx Specification

| Alloy | AA1xxx (AA1050,AA1060,AA1070,AA1100 etc.) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm--20mm |

| Width | 10mm--1500mm |

| Standard | GB/T 3880-2006 |

5. FAQ ofDiamond Embossed Aluminum Sheets 1xxx

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Diamond Embossed Aluminum Sheets 1xxx products.

B. Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: What specific considerations or precautions should be taken into account when using aluminum sheets in environments with high moisture levels?

- <p>When using aluminum sheets in damp or wet environments, it's important to consider the potential for corrosion. While aluminum is generally corrosion-resistant due to its protective oxide layer, it can still be susceptible to certain types of corrosion in the presence of moisture, especially if the environment is acidic or saline. It's crucial to use high-quality aluminum alloys that are designed for such conditions. Additionally, proper surface treatment such as anodizing or applying protective coatings can enhance resistance to corrosion. Regular inspections and maintenance are also recommended to check for signs of corrosion and to address any issues promptly.</p>

- Q: Can aluminum sheets be utilized as a material for constructing caravan roofs?

- <p>Yes, aluminum sheets can be used for caravan roofs. They are lightweight, durable, and resistant to corrosion, making them an ideal material for this purpose. Aluminum sheets are easy to install and maintain, and they can also reflect heat, helping to keep the interior of the caravan cooler. However, it's important to ensure that the aluminum sheets are of good quality and properly sealed to prevent water ingress and to maintain structural integrity over time.</p>

- Q: Can aluminum sheet be used for soundproofing?

- To a certain degree, aluminum sheet can indeed be utilized for soundproofing. Its dense and rigid composition makes it proficient in obstructing sound transmission. By combining it with other soundproofing materials like foam or mineral wool, its soundproofing capabilities can be further augmented. Nevertheless, it is crucial to acknowledge that aluminum sheet alone may not deliver absolute soundproofing since its thinness can still permit some sound to penetrate. Moreover, ensuring proper installation and sealing of all gaps and openings is imperative to maximize the soundproofing efficacy of aluminum sheet.

- Q: Are aluminum sheets suitable for automotive applications?

- Yes, aluminum sheets are suitable for automotive applications. They are lightweight, corrosion-resistant, and offer excellent strength-to-weight ratio, making them ideal for various components in vehicles such as body panels, hoods, doors, and engine parts.

- Q: what will happen when aluminum sheet is put into copper chloride solution?

- the chemical equation of the reaction, 2Al+3CuCl2=2AlCl3+3Cu, the phenomena when aluminum sheet is put into copper chloride solution: there is red solid generating on the surface of aluminum sheet.

- Q: Don't you know how you can grind a pair of scissors along a piece of paper to make it curly? Would that work with aluminum foil? I have to make a sculpture for my 3D class and I need to know if this would work before I go off and buy any.

- yes is it possible to make a ribbon out of aluminum foil if it is should i use the shiny or matte side for further ribbons out aluminum foil detail see here:

- Q: How does 1200X1200X15 6061 aluminum, CNC processing, the plane degree can reach the number of my clients to 0.2, but I used to use the MS 1000X1500X70 to the material processing, the flatness is only 1, please experienced friend to help, thank you

- Buy aluminum plate before processing, we must plastic, rolling. Processing should leave margin, release the stress, no precision requirements of the hole to do first, after the two plastic. In the semi gold processing, plastic grinding before finishing. We do that every big 700*700*12, and do the flatness down 0.03-005.

- Q: What are the common thicknesses of aluminum sheets used in transportation industry?

- Aluminum sheets are widely utilized in the transportation sector for various purposes due to their lightweight, durability, and ability to resist corrosion. In this industry, the thickness of aluminum sheets typically falls within the range of 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). When it comes to automotive body panels, which necessitate a balance between weight reduction and structural integrity, the preferred thickness of aluminum sheets is usually between 0.040 inches (1.02 mm) and 0.063 inches (1.6 mm). These particular thicknesses ensure sufficient strength while effectively reducing the overall weight of the vehicle compared to steel counterparts. In the aerospace field, where weight reduction is of utmost importance, thinner aluminum sheets are commonly employed. Typically, thicknesses ranging from 0.025 inches (0.63 mm) to 0.040 inches (1.02 mm) are used in the construction of aircraft structures, including wings, fuselage panels, and interior components. It is important to note that the specific thicknesses of aluminum sheets in the transportation industry may vary depending on the particular application, regulatory requirements, and design factors. Thus, it is crucial to consult the relevant industry standards and specifications for accurate information regarding the recommended thicknesses for different transportation applications.

- Q: Are aluminum sheets suitable for heat sinks?

- Aluminum sheets are well-suited for heat sinks. They are a lightweight and highly conductive metal, making them a great choice for dissipating heat. With their high thermal conductivity, they efficiently transfer heat away from the source and distribute it over a larger surface area. Moreover, aluminum exhibits good corrosion resistance, which is crucial for heat sinks that may come into contact with moisture or other environmental elements. The flexibility and ease of working with aluminum sheets also allow for the creation of various heat sink designs to meet specific cooling needs. In summary, aluminum sheets are extensively employed in heat sink applications due to their exceptional thermal conductivity, lightweight nature, resistance to corrosion, and ease of fabrication.

- Q: Can aluminum sheets be used for architectural applications?

- Yes, aluminum sheets can definitely be used for architectural applications. Aluminum is a versatile and lightweight material that offers numerous advantages for architectural projects. Its durability, corrosion resistance, and ability to withstand extreme weather conditions make it ideal for various architectural applications such as roofing, cladding, facades, windows, doors, and decorative elements. Aluminum sheets are available in a wide range of thicknesses, finishes, and colors, allowing architects and designers to achieve their desired aesthetic while maintaining structural integrity. The material can be easily shaped, bent, and formed into complex designs, providing flexibility and creative freedom to architects. In addition to its aesthetic appeal, aluminum is also a sustainable choice for architectural applications. It is a highly recyclable material, with a high recycling rate, making it an environmentally friendly option. Using aluminum sheets in architectural projects can contribute to reducing the carbon footprint and promoting sustainable design practices. Furthermore, aluminum sheets offer excellent thermal and acoustic properties, contributing to energy efficiency and sound insulation in buildings. The material can help reduce energy consumption and enhance occupant comfort, making it an attractive choice for architects and building owners. Overall, aluminum sheets are a popular choice in architectural applications due to their versatility, durability, sustainability, and aesthetic appeal. They offer numerous benefits and can be used in various ways to create stunning architectural designs while ensuring long-lasting performance.

Send your message to us

Aluminum Diamond Plate Sheets in Denver - Diamond Embossed Aluminum Sheets 1xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords