Ac Outdoor Unit Aluminum Coil Price - Aluminum Coils 1xxx D.C Mill Finished

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

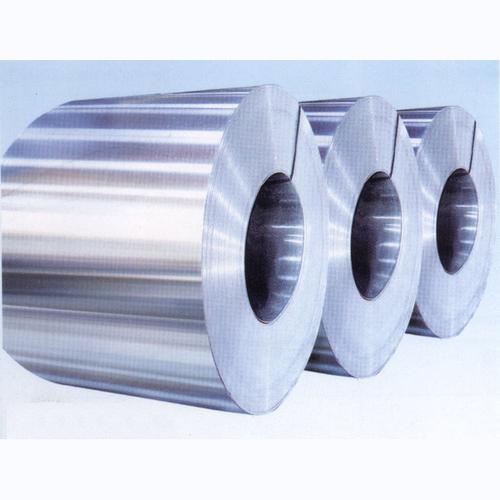

1.Structure of Aluminum Coils 1xxx D.C Mill Finished Description

Aluminum Coils 1xxx D.C Mill Finished has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Coils 1xxx D.C Mill Finished is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Coils 1xxx D.C Mill Finished

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.Aluminum Coils 1xxx D.C Mill Finished Images

4.Aluminum Coils 1xxx D.C Mill Finished Specification

| Alloy | AA1xxx (AA1050,AA1060,AA1070,AA1100 etc.) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm--100mm |

| Width | 30mm--1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Coils 1xxx D.C Mill Finished

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Coils 1xxx D.C Mill Finished products.

B.When will you deliver the products?

The Aluminum Coils 1xxx D.C Mill Finished will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Is it safe and effective to use an oven to heat an aluminum coil?

- <p>Yes, you can use an oven to heat an aluminum coil, but with caution. Aluminum has a high melting point and can withstand high temperatures, making it suitable for heating in an oven. However, it's crucial to ensure that the coil is clean and free of any non-stick coatings or residues that could produce toxic fumes when heated. Additionally, monitor the temperature and duration of heating to avoid overheating, which might cause the coil to warp or degrade. Always follow safety guidelines and manufacturer's instructions for your specific oven and aluminum coil.</p>

- Q: Is it possible to utilize a punching machine to create holes in steel coils for decorative purposes?

- <p>Yes, you can use a punching machine to punch holes in steel coils for decoration purposes. Punching machines are designed to create precise holes in various materials, including steel. For steel coils, ensure the machine is capable of handling the thickness and hardness of the steel. It's important to select the right punch and die material, and consider the coil's strength and ductility. Always follow safety guidelines and machine specifications to prevent damage or injury.</p>

- Q: A bit of a question for the 1911 experts roaming around here. Per-say someone, who knew their way around a 1911 built one on an aluminum frame. To top it all off, if the finished gun were to be chambered in .38 super... how long would this combination last? I've heard horror stories about aluminum frames, and then I've heard some wonderful things... this question was to see if anyone had ever thought about/done this sort of thing before. Something tells me that Aluminum + .38 super wouldn't last too long... Most informative answer gets the ten point prize as usual.

- Aluminum might be corrosive resistant but it is softer than a stainless steel frame. It might be possible to shoot .38 super regular loads through it but any .38 super + P might cause a catastrophic failure of the weapon. Just my opinion.

- Q: This question asks for a method to calculate the diameter of an aluminum coil using its weight and density.

- <p>To calculate the diameter of an aluminum coil based on its weight and density, you first need to know the volume of the coil. The formula for volume (V) is V = mass (m) / density (蟻). Once you have the volume, you can use the formula for the volume of a cylinder, V = 蟺r虏h, where r is the radius and h is the height (or length) of the coil. If you know the height of the coil, you can solve for the radius and then double it to find the diameter (D = 2r). Ensure you have consistent units for all measurements. This calculation assumes the coil is cylindrical and uniform in thickness.</p>

- Q: Can aluminum coils be used in the production of cryogenic storage tanks?

- Cryogenic storage tanks can incorporate aluminum coils, as aluminum is a suitable material for such purposes. This is due to its low density, high thermal conductivity, and excellent resistance to corrosion. These attributes make it an excellent choice for the storage and transportation of cryogenic liquids like liquid nitrogen, oxygen, and argon. Aluminum coils can be utilized to construct the internal shell of the tank, which offers a lightweight and durable solution. Moreover, aluminum is highly malleable, enabling the creation of intricate tank shapes and designs. However, it is crucial to consider that aluminum has a higher coefficient of thermal expansion compared to materials such as stainless steel. Therefore, adequate design measures must be implemented to accommodate thermal contraction and expansion during cryogenic operations.

- Q: I am a college student living in a private apartment and I use up lots of aluminium foils to cook and eat. I use aluminium foils as plates because I am too lazy to clean plates. I want to know how environment-unfriendly i am for doing so. How bad am I compared to the guy who keeps on drinking from cans without recycling them?

- idk but i sure hope u are recycling all that foil

- Q: Can aluminum coils be used in the production of architectural panels?

- Yes, aluminum coils can be used in the production of architectural panels. Aluminum is a versatile material that is widely used in the construction industry due to its lightweight, durability, and corrosion resistance. Aluminum coils, which are typically made by rolling aluminum ingots into thin, flat sheets, provide a convenient and efficient way to produce architectural panels. Architectural panels, such as aluminum composite panels (ACP) or solid aluminum panels, are commonly used as cladding systems for buildings. These panels serve both functional and aesthetic purposes, providing weather protection, insulation, and enhancing the overall appearance of the structure. Aluminum coils are used in the production of architectural panels because they can be easily formed and shaped into various panel designs, such as flat sheets, corrugated panels, or custom profiles. The coils can be cut to size and then processed through various techniques, including bending, folding, punching, or welding, to create the desired panel shape and dimensions. Furthermore, aluminum coils offer a wide range of finishing options, such as anodizing, powder coating, or painting, which allows for customization and enhances the aesthetic appeal of architectural panels. These finishes not only provide color options but also improve the durability and weather resistance of the panels. In summary, aluminum coils are suitable for the production of architectural panels due to their versatility, durability, and aesthetic options. Their use in the construction industry has become increasingly popular, as they offer a cost-effective and efficient solution for creating high-quality panels that meet the functional and design requirements of modern architecture.

- Q: im doing an a level physics presentation on aluminium and im trying to compare aluminium and copper in electricity pylons.i know that copper will have a better conductance than aluminium becasue it has a lower resitivity but i need to come up with a calculation to prove why aluminium is better for use in electricity pylons? i know its down to aluminium being more lightweight than copper and also much cheaper. But im not sure how to create an calculation to show this?:) any help is greatly appreciated

- Copper has lower resistance per unit volume, ie, a 1 cm diameter copper wire has less resistance than a 1 cm aluminum wire. BUT, aluminum is much lighter than Cu for the same diameter. If you used an aluminum wire that weighs the same as the 1 cm diameter copper wire, it would have LOWER resistance. And that is why aluminum is used in power transmission, and also in aircraft, where weight is important. to do this you calculate density resistivity which is (resistivity x density). Here is a partial table: Al 28.2e-9 Ω-m * 2700 kg/m? = 76e-6 Ω-kg/m? Cu 17.2e-9 Ω-m * 8960 kg/m? = 154e-6 Ω-kg/m? Ag 15.9e-9 Ω-m * 10500 kg/m? = 167e-6 Ω-kg/m? Au 22.14e-9 Ω-m * 19300 kg/m? = 427e-6 Ω-kg/m? Zn 68e-9 Ω-m * 7130 kg/m? = 485-6 Ω-kg/m? Fe 100e-9 Ω-m * 7870 kg/m? = 787e-6 Ω-kg/m? Note that Al is half that of Cu.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum coils in food storage.

- <p>Advantages of using aluminum coils for storing food include their excellent heat conductivity, which allows for even heating and cooling, making them ideal for temperature-sensitive food items. They are also lightweight, durable, and resistant to corrosion, which enhances their longevity. Additionally, aluminum coils are recyclable, contributing to environmental sustainability. Disadvantages include potential health concerns due to the leaching of aluminum into food, especially in acidic environments. There's also the risk of denting or scratching the surface, which can compromise the integrity of the coil and lead to contamination. Moreover, aluminum coils may not be suitable for all types of food storage, particularly those requiring airtight or vacuum sealing.</p>

- Q: How do aluminum coils compare to zinc coils in terms of durability?

- The durability of aluminum coils and zinc coils is influenced by their different properties. Aluminum coils are highly durable due to their excellent corrosion resistance. They naturally develop an oxide layer that acts as a protective barrier against rust and degradation. This makes them ideal for use in coastal areas or locations with high humidity levels. In contrast, zinc coils, specifically galvanized steel coils, are coated with a layer of zinc to enhance their corrosion resistance. The zinc coating acts as a sacrificial layer, corroding first and protecting the underlying steel from rust. As a result, zinc coils are also highly durable and can withstand harsh conditions where the steel substrate is exposed to moisture or chemicals. Although both aluminum and zinc coils offer good durability, aluminum coils have an advantage in terms of corrosion resistance. Their natural oxide layer provides continuous protection, while zinc coils rely on the sacrificial zinc coating, which can gradually wear off over time. However, the overall durability of both types of coils depends on factors such as maintenance, usage, and the specific environment in which they are installed.

Send your message to us

Ac Outdoor Unit Aluminum Coil Price - Aluminum Coils 1xxx D.C Mill Finished

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords