Aluminum Coil 1050 1200 3004 H14 H24 5052 for Composite Panel on Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1) alloy number: 1050 1060 1100 1200 3003 3004 3105 3A21.

2) temper available: O H12 H14 H16 H18 H22 H24 .

3) application: mechanical components,bottle caps,construction materials, Roofing materials; Car license plate, Road signs;cookware bottom plates, Fry pans,Tea kettles,Pressure cookers

4) thickness: 0.2-10mm.(+/-0.02mm)

5) diameter: 20-2500mm.(+/-0.5mm)

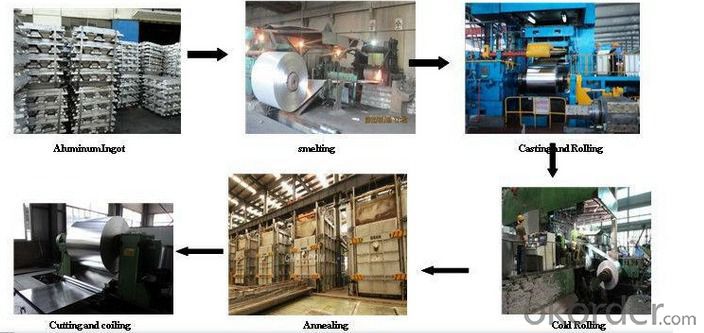

6) production treatment: cold rolled or hot rolled.

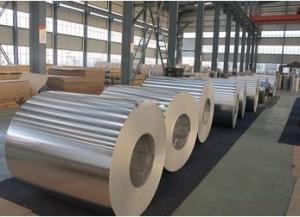

7) surface appearance: flat clean surface no whole, scratch, oil dirty and oxidation.

8) cutting edge: neat cutting edge no burrs.

Chemistry Composition & Mechanical Properties

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

1060 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.6 | ||

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.5 | ||

1100 | 0.95 | 0.05-0.2 | 0.05 | 0.1 | 99.0 | |||||

1200 | 1.0 | 0.05 | 0.05 | 0.1 | 0.05 | 99.0 | ||||

3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | 0.1 | remainder | ||||

Surface

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Discoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

Surface without black line, clean cut, periodic stain, roller printing defects, such as other gko internal Control standards.

You can't see any tiny space between the plates when they are piled up. And the surface is smoothly without freckles.

We have strict and professional procedures of production:

Certification

Product quality and ISO certification are the major factors that have raised our credibility in the industry. Keeping this in mind, We practice advanced manufacturing techniques and scrutinize each product on various quality parameters. To ensure international standards of quality in our range, we manufacture these products using quality tested metals and alloys.

FAQ of Aluminium Coil for ACP (Aluminum Composite Panel):

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q: What are the transportation and storage requirements for aluminum coils?

- The transportation and storage requirements for aluminum coils involve careful handling and protection. During transportation, coils should be securely strapped or loaded onto pallets to prevent damage or shifting. They should be transported using appropriate equipment, such as flatbed trucks, to avoid bending or distorting the coils. Additionally, coils should be stored in a clean, dry, and well-ventilated area to prevent corrosion. They should be stored horizontally, with proper support to avoid any deformation. Proper labeling and documentation are also necessary for tracking and identification purposes.

- Q: Can aluminum coils be customized to specific requirements?

- Yes, aluminum coils can be customized to specific requirements. Aluminum coils are highly versatile and can be tailored to meet a wide range of specifications and applications. Customization options include the choice of alloy, thickness, width, and length of the coil, as well as various surface treatments such as coatings, finishes, and embossing. Additionally, aluminum coils can be customized in terms of mechanical properties, such as strength, flexibility, and corrosion resistance, to suit specific needs. The customization process involves working closely with manufacturers or suppliers who have the expertise and facilities to meet the desired requirements. Whether it's for the aerospace industry, automotive sector, construction projects, or any other application, aluminum coils can be customized to meet specific requirements and deliver optimal performance.

- Q: My mom was being an idiot and used the steel spatula to scrape the cookies off an aluminum cookie sheet. Now there are small bits of aluminum on the bottom of the cookies. I just ate a few of them (5) before i noticed it, should I be worried?

- It would only be a problem if you constantly expose yourself to aluminum filings. Heavy metals (things like lead or mercury) are toxic to people. What most people don't realize is that that in order for these metals to be toxic, you have to be exposed to them for a long period of time and in fairly large quantities. In general, lead is in your tap water. You've probably accidently drank more aluminum filings from soda cans than you have eaten from those cookies. Still though, there is no point in trying to expose yourself to something you know you shouldn't have in your body. So I wouldn't eat any more.

- Q: My favorite deodorant contains aluminum. It smells really good and it works really well.My mom doesn't like me using it because it contains aluminum.So I got aluminum free. It doesn't smell at all (I can't seem to find fragrant aluminum free deodorant) and it doesn't work as well, for some reason.I want to keep using the one with aluminum, but will it be harmful to me in the future?

- all of my deodorants have aluminum in them. practically every deodorant that works out there has aluminum in it. the only one i know of that DOESN'T have aluminum is Tom's Natural and it doesn't work at ALL. See the aluminum is the key ingredient that stops you from sweating and stops odor, that's why it works so much better than your new aluminum-free one. But then again, use it wisely, because it's linked to alzeimer's, brain cancer, etc.

- Q: Can aluminum coils be used for roofing applications?

- Yes, aluminum coils can be used for roofing applications. Aluminum is a popular choice for roofing due to its lightweight nature, durability, and resistance to corrosion. It is commonly used for both residential and commercial roofing projects.

- Q: What are the factors that determine the price of aluminum coils?

- There are several factors that determine the price of aluminum coils. One of the main factors is the cost of raw materials. The price of aluminum is influenced by factors such as supply and demand, global economic conditions, and production costs. Fluctuations in these factors can directly impact the price of aluminum coils. Another factor that determines the price of aluminum coils is the manufacturing process. The cost of processing aluminum into coils involves various expenses such as labor, energy, and equipment. The complexity of the manufacturing process and the efficiency of the production line can affect the overall cost, which in turn influences the price of aluminum coils. Market conditions also play a crucial role in determining the price of aluminum coils. Factors such as market competition, industry trends, and geographic location can impact pricing. For instance, if there is a high demand for aluminum coils in a particular region but limited supply, the price may increase due to the scarcity of the product. Additionally, transportation and logistics costs contribute to the final price of aluminum coils. The distance between the manufacturing facility and the customer, as well as the mode of transportation, can affect the shipping expenses. These costs are typically factored into the overall price of the coils. Lastly, government policies and regulations can influence the price of aluminum coils. Tariffs, import taxes, and trade agreements may impact the cost of importing or exporting aluminum coils, thereby affecting the final price. In conclusion, the price of aluminum coils is determined by various factors including the cost of raw materials, manufacturing processes, market conditions, transportation costs, and government policies. It is essential for manufacturers and consumers to consider these factors when analyzing and forecasting the price of aluminum coils.

- Q: Can aluminum coils be welded or joined?

- Aluminum coils have the capability to be welded or joined. Aluminum, being a highly weldable metal, can be easily joined through the utilization of different welding techniques. TIG welding, MIG welding, and resistance welding are the most commonly employed methods for welding aluminum coils. TIG welding is a precise and adaptable technique that employs a non-consumable tungsten electrode to generate the arc. This method is extensively utilized in welding aluminum coils due to its ability to offer exceptional control over the welding process, resulting in welds of high quality and strength. On the other hand, MIG welding employs a consumable wire electrode and a shielding gas to safeguard the weld zone from atmospheric contamination. This technique is faster compared to TIG welding and is often favored for larger production runs. Resistance welding is yet another prevalent method employed for joining aluminum coils. It involves the passage of an electric current through the overlapping metal surfaces to generate heat and pressure, thereby creating a robust weld joint. This technique is commonly used in industries that require high-speed production. It is important to note that welding aluminum coils necessitates specific techniques and considerations due to the distinctive properties of the metal. Aluminum possesses a lower melting point and higher thermal conductivity than other metals, which can make the welding process more challenging. Proper cleaning, preheating, and the selection of suitable filler materials are crucial in achieving successful welds. To summarize, aluminum coils can be welded or joined using various techniques such as TIG welding, MIG welding, and resistance welding. However, it is imperative to adhere to proper procedures and take into account the specific properties of aluminum to ensure the creation of strong and dependable welds.

- Q: How are aluminum coils used in gutter systems?

- Gutter systems commonly incorporate aluminum coils due to their durability and resistance to corrosion. These coils enable the creation of seamless gutters that are custom-fitted to the specific dimensions of a structure, preventing water damage to the roof and foundation. To begin the process, an aluminum coil is fed through a specialized machine known as a gutter machine. This machine transforms the coil into a gutter shape, typically in a continuous length that can extend the entire length of the roofline without any seams. The coil is molded into a trough-like structure with a slight slope, facilitating the easy flow of water towards downspouts. Aluminum is an ideal material for gutter systems because it is lightweight yet robust, simplifying installation and minimizing the risk of sagging or bending. It is also highly resistant to rust and corrosion, ensuring the longevity of the gutter system even in harsh weather conditions. Additionally, aluminum can be easily painted or coated to match the aesthetic of the building. Once the seamless gutters are formed from the aluminum coil, they are typically secured to the roofline's edge using hangers or brackets. Downspouts are then affixed to strategic points on the gutters to redirect the collected rainwater away from the building's foundation. These downspouts can also be fashioned from aluminum coils, maintaining a seamless and cohesive appearance throughout the entire gutter system. In conclusion, aluminum coils are utilized in gutter systems to produce seamless gutters that offer effective and efficient water drainage. Their durability, resistance to corrosion, and ease of installation have contributed to their popularity in residential, commercial, and industrial buildings.

- Q: Can aluminum coils be used in the production of military equipment?

- Yes, aluminum coils can be used in the production of military equipment. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various military applications, such as aircraft components, armored vehicles, and weapon systems. Its strength to weight ratio and ability to withstand harsh environments make it an ideal choice for military equipment manufacturing.

- Q: This question asks about the impact of aluminum coils on food quality, considering possible effects on taste, safety, and preservation.

- <p>Aluminum coils, when used in cooking or food packaging, can potentially affect the quality of food. If aluminum leaches into the food, it may alter the taste and could pose health risks due to aluminum's neurotoxic properties. However, modern food-grade aluminum coils are coated or anodized to prevent such leaching, ensuring food safety. They are also used in heat transfer for cooking, which can improve the efficiency and evenness of cooking, thus enhancing food quality. It's crucial to use high-quality, food-safe aluminum coils to avoid any negative impact on food quality and safety.</p>

Send your message to us

Aluminum Coil 1050 1200 3004 H14 H24 5052 for Composite Panel on Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords