Aluminum 4x8 Sheets Diamond Aluminium Tread Plates 1xxx 3xxx 5xxx Series for Boat Toolbox

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

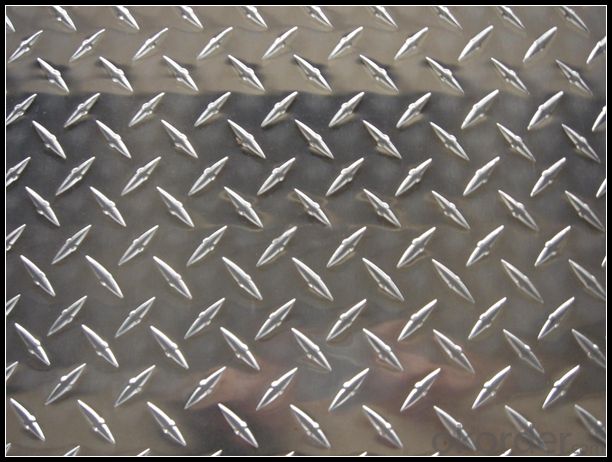

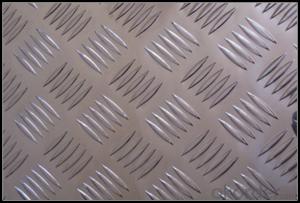

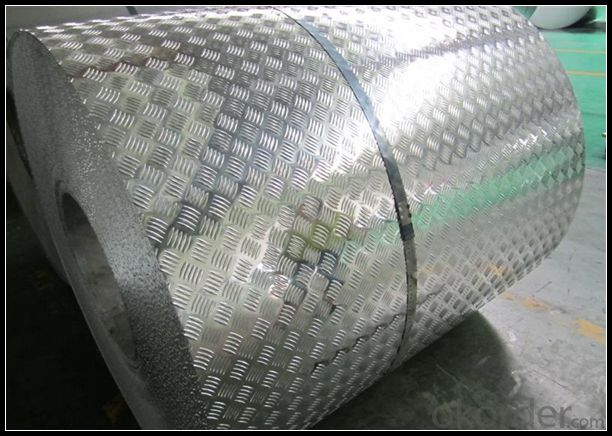

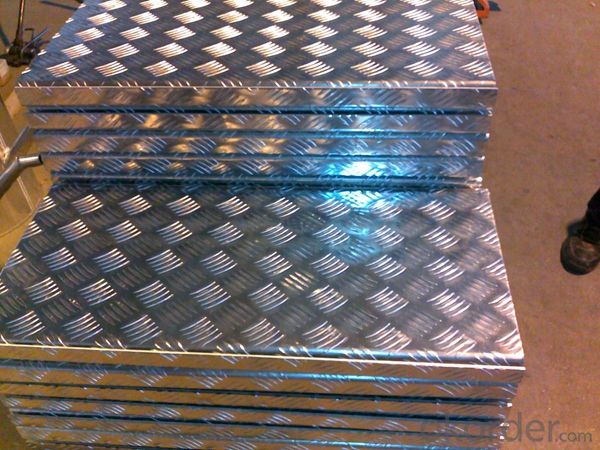

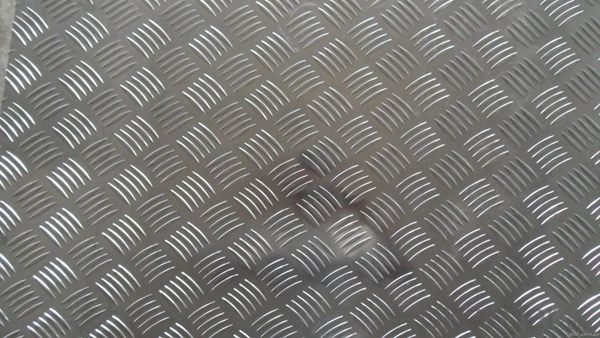

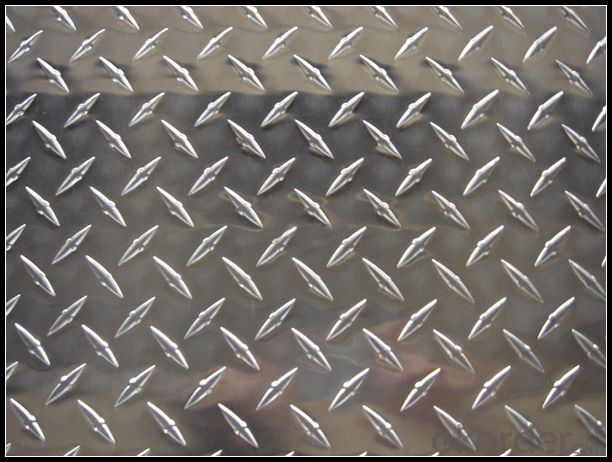

Diamond Aluminium Tread Plates 1xxx 3xxx 5xxx Series for Boat Toolbox

1.Structure of Diamond Aluminium Tread Plates 1xxx 3xxx 5xxx Series for Boat Toolbox

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Diamond Aluminium Tread Plates 1xxx 3xxx 5xxx Series for Boat Toolbox

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Diamond Aluminium Tread Plates 1xxx 3xxx 5xxx Series for Boat Toolbox Images

4.Specification of Diamond Aluminium Tread Plates 1xxx 3xxx 5xxx Series for Boat Toolbox

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Diamond Aluminium Tread Plates 1xxx 3xxx 5xxx Series for Boat Toolbox

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for an identification of various types of aluminum sheets that are typically utilized in construction projects.

- <p>Aluminum sheets used in construction come in various types, each with specific properties and applications. Common types include: 1) Mill Finish Sheets: These have a natural aluminum finish and are used for applications requiring a raw aluminum look. 2) Painted Aluminum Sheets: Coated with paint for enhanced durability and color options, suitable for exterior applications. 3) Anodized Aluminum Sheets: Durable and corrosion-resistant, often used for architectural features. 4) Embossed Aluminum Sheets: Offered with various textures for design purposes. 5) Perforated Aluminum Sheets: Used for decorative or functional purposes, such as ventilation. 6) Aluminum Composite Material (ACM) Sheets: Consisting of two aluminum sheets with a non-aluminum core, used for cladding. Each type is chosen based on the project's specific requirements for aesthetics, strength, and environmental resistance.</p>

- Q: Can aluminum sheets be used for modular construction?

- Yes, aluminum sheets can be used for modular construction. Aluminum is a versatile and lightweight material that offers several benefits for modular construction projects. It is durable, corrosion-resistant, and has a high strength-to-weight ratio, making it suitable for various structural applications. Aluminum sheets can be easily fabricated and formed into different shapes and sizes, allowing for flexibility in design and construction. Additionally, aluminum is recyclable, making it an environmentally friendly choice for sustainable construction practices. Overall, aluminum sheets are a viable option for modular construction due to their strength, durability, and versatility.

- Q: I have heard that consuming aluminum can increase your risk for Alzheimer's later in life.Knowing this, would it increase my risk to eat sweet potatoes cooked in aluminum foil?Even if there is a negligible risk, I still want to know for curiosity reasons.Thank You

- No, I don't think it is dangerous to eat food baked in either side (shiny or matte side) in an aluminum foil. It is dangerous though to put aluminum foil inside a microwave oven to cause those electromagnetic fields to catch fire unless you have a microwave with a cavity magnetron tube to reflect the electromagnetic fields and also don't try to chew and ingest the aluminum foil

- Q: Aluminum alloy cable tray is made of a series of aluminum sheets, a series of pure aluminum aluminum plate can do?

- Do you fold it with aluminium plate? It should be about the same. The cold rolled aluminum of the 1 series is still a little bit stronger,I understand the shape of the material, and if the aluminum extrusion molding, direct use of 6063 is the most appropriate.

- Q: What are the different fabrication methods used for aluminum sheets?

- There are several different fabrication methods used for aluminum sheets, each with its own advantages and applications. Some of the most common methods include rolling, extrusion, casting, and stamping. Rolling is the most commonly used method and involves passing the aluminum through a series of rollers to reduce its thickness and create a flat sheet. This method allows for precise control over the thickness and shape of the sheet, making it ideal for a wide range of applications, from packaging to building materials. Extrusion is another popular method where heated aluminum is forced through a die to create a specific shape or profile. This method is commonly used for creating complex shapes such as tubes, rods, and channels. Extruded aluminum sheets offer high strength and durability, making them suitable for structural applications in industries like construction and automotive. Casting involves pouring molten aluminum into a mold and allowing it to solidify. This method is often used for creating intricate and detailed shapes that cannot be easily achieved through other methods. Casting can produce aluminum sheets with unique textures and designs, making them popular in decorative applications. Stamping is a method that uses a press to shape the aluminum sheet by applying pressure and forming it into a desired shape. This technique is commonly used for creating small, precise parts like brackets, connectors, and electrical components. Stamped aluminum sheets offer excellent dimensional accuracy and can be produced in high volumes at a relatively low cost. In addition to these methods, other fabrication techniques such as welding, bending, and laser cutting can be used to further process aluminum sheets and create custom shapes and designs. Overall, the choice of fabrication method for aluminum sheets depends on the desired application, required properties, and complexity of the desired shape. Each method offers unique advantages and capabilities, allowing for a wide range of possibilities in terms of aluminum sheet fabrication.

- Q: What is the thermal expansion coefficient of aluminum sheets?

- The thermal expansion coefficient of aluminum sheets typically ranges from 22 to 24 x 10^-6 per degree Celsius.

- Q: Are aluminum sheets suitable for electrical connectors?

- Indeed, electrical connectors can be effectively made using aluminum sheets. Aluminium, being a metal with high conductivity, is an ideal option for facilitating the flow of electric current. Its low electrical resistance enables the efficient transmission of electricity. Moreover, aluminum is renowned for its lightweight properties, resistance to corrosion, and affordability, rendering it a favored choice for electrical connectors across diverse sectors like automotive, aerospace, and electronics. Nevertheless, it should be emphasized that when aluminum connectors are utilized alongside dissimilar metals, extra precautions might be necessary to avert the occurrence of galvanic corrosion.

- Q: why is copper sheet but not aluminum sheet that becomes the negative pole after putting copper sheet and aluminum sheet connected with wire into concentrated nitric acid?

- According to metal reactivity series order table, aluminum has a better metallicity, but it will be passivated soon after contacting concentrated sulfuric acid, and won’t react again. But copper and concentrated sulfuric acid can react continually. So aluminum sheet becomes the positive pole after passivation.

- Q: What is a composite aluminum plate?

- APCP (also called APCP) as a new type of decorative materials, since the last century at the end of 80s early 90s from South Korea to China, with its economy, optional color diversity, convenient construction method, excellent processing performance, excellent fire resistance and noble quality, quickly favored by people.Abroad, the name of aluminum plate has many kinds, there is called "aluminum composite board" (Aluminum Composite)Panels) there is called aluminum composite (Aluminum, Composite)Materials) in many European countries, the aluminum plate is Alucobond, a trademark derived from the aluminum-plastic plate. There are not many enterprises producing aluminum-plastic plate abroad, but the scale of production is very large. Well known are the Swiss based Alusuisse company and the Reynolds Metal Co in the United StatesJapan, Mitsubishi Co, Korea Daming, etc.. Taiwan auspicious, famous enterprises, Jiangxi Thailand, Alice Alex Hua Tian, Shanghai Huayuan, Ningbo aihome aluminum building materials.

- Q: Is aluminum sheet recyclable?

- Yes, aluminum sheet is highly recyclable. Aluminum is one of the most sustainable and environmentally friendly materials, as it can be recycled indefinitely without losing its quality. The recycling process of aluminum sheet involves melting it down to its liquid form, which requires significantly less energy compared to the production of primary aluminum from raw materials. Recycling aluminum sheet not only conserves natural resources but also reduces greenhouse gas emissions and saves energy. It is estimated that recycling one ton of aluminum sheet saves about nine tons of CO2 emissions. Therefore, aluminum sheet recycling is not only economically viable but also an essential practice for maintaining a sustainable and eco-friendly environment.

Send your message to us

Aluminum 4x8 Sheets Diamond Aluminium Tread Plates 1xxx 3xxx 5xxx Series for Boat Toolbox

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords