Aluminum 3003 Alloy PE Coated Aluminum Coils for Composite Panels

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PE Coated Aluminium Coils 3003 Alloy Used for Aluminum Composite Panels

We normally used PVDF coated aluminum coils 3003 for building materials.

3003 is very good in high strength, corrosion resistance, high weather resistance and other characteristics.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of PE Coated Aluminium Coils 3003 Alloy Used for Aluminum Composite Panels

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

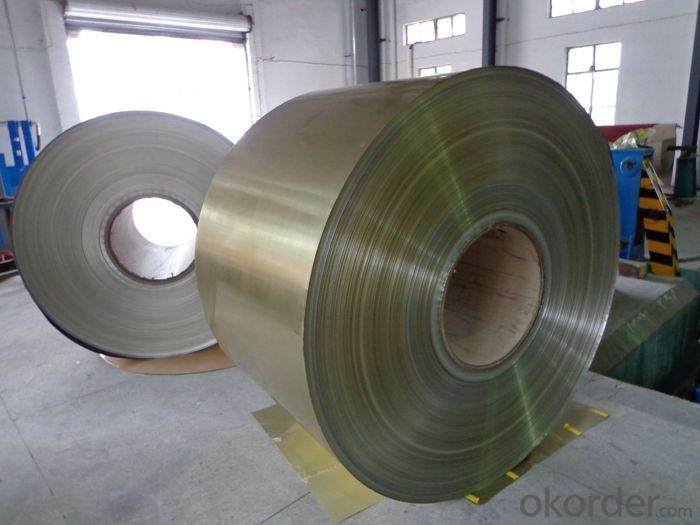

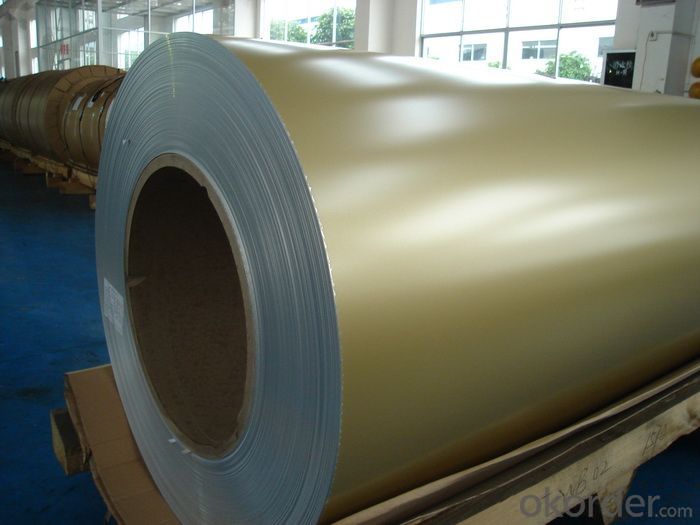

3. PE Coated Aluminium Coils 3003 Alloy Used for Aluminum Composite Panels Images

4. Specification of PE Coated Aluminium Coils 3003 Alloy Used for Aluminum Composite Panels

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: This question asks about the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in construction due to its lightweight, high strength, and corrosion resistance. It is commonly used in window frames, door frames, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum is also utilized in structural components such as beams and columns, as well as in the manufacturing of prefabricated buildings. Additionally, it is used in the electrical wiring and conduits within buildings due to its excellent conductivity. Its versatility makes it a popular choice for both residential and commercial construction projects.</p>

- Q: Is it possible to utilize aluminum in the creation of innovative battery technologies?

- <p>Yes, aluminum can be used to make new types of batteries. Aluminum-air batteries, for instance, are a type of metal-air battery that uses aluminum as the anode and air as the cathode. These batteries have a high energy density and are lightweight, making them suitable for certain applications like electric vehicles and backup power systems. Research is ongoing to improve the efficiency and lifespan of aluminum-based batteries, addressing issues such as aluminum corrosion and the development of efficient air cathodes.</p>

- Q: Explain the natural relationship between aluminum and magnesium, focusing on their abundance and reactivity in the Earth's crust.

- <p>Aluminum and magnesium are both abundant elements in the Earth's crust, with aluminum being the most abundant metal and magnesium being the eighth most abundant element overall. They are often found in close association within the same minerals, such as in aluminosilicates and some carbonates. Both elements are highly reactive, forming compounds readily with oxygen to create oxides and silicates. However, they differ in their reactivity with water; aluminum forms a protective oxide layer that prevents further reaction, while magnesium reacts more readily with water to form magnesium hydroxide. This difference in reactivity influences their distribution and the types of compounds they form in nature.</p>

- Q: Explain the distinction between primary and secondary aluminum recycling, including the processes involved in each.

- <p>Primary aluminum recycling involves the production of aluminum from bauxite ore through a process called electrolysis. This process is energy-intensive and requires significant resources. Secondary aluminum recycling, on the other hand, involves the recycling of aluminum products back into new aluminum products. This process is much more energy-efficient as it involves melting and recasting the aluminum, which requires only 5% of the energy needed for primary production. Secondary recycling is more sustainable and environmentally friendly due to its lower energy consumption and reduced waste.</p>

- Q: Is it possible to utilize aluminum in the manufacturing process of solar panels?

- <p>Yes, aluminum is indeed used in the production of solar panels. It is primarily employed as a component of the frame that supports and protects the panel. Aluminum's light weight, high strength, and corrosion resistance make it an ideal material for this purpose. Additionally, aluminum can be used in the backsheet of the solar panel, providing structural support and helping to protect the panel from environmental factors. However, aluminum is not used in the actual photovoltaic cells that convert sunlight into electricity; those are typically made from silicon.</p>

- Q: What is the chemical formula that represents aluminum?

- <p>The chemical formula for aluminum is Al. It is a lightweight, silvery-white metal that is found in the Earth's crust and is the most abundant metal there. Aluminum is a member of the boron group of chemical elements and is represented by the symbol Al, which is derived from the Latin word 'alumen', meaning alum.</p>

- Q: Can recycled aluminum be utilized in the production of solar panels and other renewable energy technologies?

- <p>Yes, recycled aluminum can be used to make solar panels and other renewable energy sources. Aluminum is a key component in solar panel frames and mounting structures due to its lightweight, high strength, and corrosion resistance. Recycling aluminum saves energy and resources compared to mining and refining new aluminum. Additionally, recycled aluminum can be used in wind turbines, hydroelectric generators, and other renewable energy technologies where its properties are beneficial. The use of recycled materials in renewable energy production contributes to a more sustainable and circular economy.</p>

- Q: This question asks about the method to determine the strength of aluminum alloy, which is a measure of its ability to withstand stress or deformation before breaking.

- <p>The strength of aluminum alloy is calculated through a series of mechanical tests, primarily the tensile test. In this test, a sample of the alloy is subjected to a gradually increasing tensile force until it fractures. The yield strength is noted at the point where the alloy begins to deform plastically, and the ultimate tensile strength (UTS) is recorded at the point of fracture. The strength is expressed in units of stress (e.g., MPa or psi). Additionally, the hardness of the alloy can be measured using tests like the Brinell or Rockwell hardness test. These values, along with other properties like elongation and reduction of area, provide a comprehensive understanding of the alloy's strength and ductility.</p>

- Q: Explain how the use of aluminum impacts energy consumption, including its production and recycling processes.

- <p>The use of aluminum has a significant impact on energy consumption, particularly in its production process. Aluminum is an energy-intensive material to produce, requiring large amounts of electricity to extract from its ore, bauxite, through a process called electrolysis. This process accounts for about 5% of global electricity consumption. However, aluminum is also highly recyclable, and recycling aluminum uses only 5% of the energy needed to produce it from raw materials. This makes aluminum recycling a more energy-efficient process, reducing the overall energy consumption related to aluminum use when recycling is prevalent.</p>

- Q: This question asks for typical applications of aluminum foil in everyday life.

- <p>Aluminum foil is commonly used for food storage, as it helps preserve freshness and prevents freezer burn. It's also used in cooking, either to cover dishes to retain moisture or to create packets for steaming or baking. In the kitchen, it's often used to line baking sheets to prevent food from sticking. Beyond cooking, aluminum foil is used for insulation, in arts and crafts, and even for cleaning purposes, such as buffing glass or polishing silverware. It's a versatile material found in many households and commercial settings.</p>

Send your message to us

Aluminum 3003 Alloy PE Coated Aluminum Coils for Composite Panels

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords