Individual Sheets of Aluminum Foil Treadplate in Stucco Pattern for Car Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium treadplate in stucco pattern for car body

Aluminium treadplate in diamond pattern for building is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium treadplate in stucco pattern for car body

Aluminum Stucco Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium treadplate in stucco pattern for car body

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium treadplate in stucco pattern for car body

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium treadplate in stucco pattern for car body

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

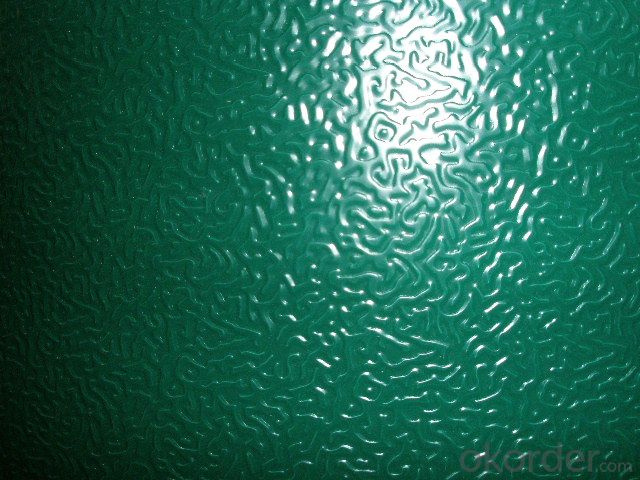

6. Image of Aluminium treadplate in stucco pattern for car body

7. Package and shipping of Aluminium treadplate in stucco pattern for car body

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: how much should the current be adjusted when I use pulse aluminum welding machine to weld 0.7 aluminum sheet?

- 60-70A current is enough for 0.7 aluminum sheet,the key poiny is that the thin sheet should be bonded with iron sheet or other assistant cooling device when you weld it, or it will be burned through.

- Q: How do aluminum sheets perform in terms of dimensional stability?

- Aluminum sheets generally exhibit good dimensional stability due to their low coefficient of thermal expansion, meaning they are less likely to warp or deform when exposed to temperature changes compared to other materials.

- Q: This question asks about the various color options available for aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors to suit various applications and aesthetic preferences. Common colors include silver (anodized), white, black, and clear (natural). Beyond these, there are also options for colors like red, blue, green, and yellow. Some manufacturers offer custom color matching services for specific projects. Additionally, aluminum sheets can be coated with various finishes such as matte, gloss, or textured, further expanding the color and appearance options. It's important to check with specific suppliers for their available color range as it can vary.</p>

- Q: Can aluminum sheet be used for decorative purposes?

- Yes, aluminum sheet can be used for decorative purposes. Its lightweight nature, durability, and versatility make it a popular choice for various decorative applications such as signage, wall cladding, ceiling panels, furniture accents, and more. Additionally, aluminum sheets can be easily manipulated, painted, or coated to achieve different finishes, colors, and textures, allowing for endless possibilities in decorative design.

- Q: Could two pieces of aluminum sheets be welded together?

- or you can use file to rub back and forth, and it needs lots of practices or you can't weld the sheets.because aluminum sheet cann't be tightly welded to tin, it's hard to weld two pieces of aluminum sheets by common welding methods.it's hard, the aluminum sheets are oxidized soon after polished by abrasive paper.and you need to cover the new polished area with soldering paste and learn some operating skills.owing to aluminum sheets' high oxidized speed, you need to wipe the aluminum sheets with soldering paste and soldering tin and rub them with large power soldering iron, then the aluminum sheets will be tightly welded to tin.so two pieces of aluminum sheets could be welded together.

- Q: I have a friend to purchase a number of aluminum, used to make computer cooling plate. He asked me to help with the supplier, can I look at the Internet, there are many kinds of aluminum, would like to ask: what kind of computer cooling plate used to do a bit better? What are the suitable suppliers in Guangdong?

- Aluminum extruded radiator:It is widely used in modern material with good heat dissipation cooling industry, most of them use 6063 T5 high quality aluminum, its purity can reach above 98%, the heat conduction ability, low density, low price so get the favor of the major manufacturers.

- Q: Can aluminum sheets be bent?

- Indeed, the bending of aluminum sheets is possible. Aluminum, being a remarkably pliable metal, can be effortlessly manipulated and molded through methods like bending, rolling, or folding. To achieve a particular angle or curve, the procedure for bending aluminum sheets entails the application of force onto the metal. This can be accomplished using specialized equipment like a brake press or through manual techniques. The adaptability of aluminum renders it a favored option for a variety of applications in the construction, automotive, and aerospace sectors, where bending or shaping is necessary.

- Q: This question asks for methods to maintain and repair aluminum sheets once they have been installed.

- <p>To maintain and repair aluminum sheets after installation, follow these steps: Regularly clean the surface with a soft cloth and mild detergent to remove dirt and grime. Avoid abrasive materials that can scratch the surface. For minor scratches or dents, use aluminum filler or touch-up paint that matches the sheet's color. Apply the filler or paint carefully, following the manufacturer's instructions. For more severe damage, consider hiring a professional to assess and repair the damage to ensure structural integrity. Always check for any signs of corrosion and address them promptly to prevent further damage. Regular maintenance will prolong the life of aluminum sheets and keep them looking their best.</p>

- Q: Are the aluminum sheets suitable for architectural applications?

- Yes, aluminum sheets are highly suitable for architectural applications. Aluminum is a versatile material that offers numerous benefits for architectural projects. It is lightweight, durable, and resistant to corrosion, making it ideal for exterior applications. Aluminum sheets can be easily shaped, formed, and manipulated to create intricate designs and structures, allowing architects to bring their creative visions to life. Additionally, aluminum is a sustainable material as it is 100% recyclable, reducing the environmental impact of architectural projects. Overall, the use of aluminum sheets in architectural applications provides both aesthetic appeal and functional durability, making it a preferred choice for architects and designers.

- Q: How do I cut aluminum sheets?

- To cut aluminum sheets, you can use a variety of tools such as a circular saw, jigsaw, or a metal shear. It is important to choose the appropriate tool based on the thickness and size of the sheet. Additionally, make sure to use proper safety precautions such as wearing gloves and eye protection.

Send your message to us

Individual Sheets of Aluminum Foil Treadplate in Stucco Pattern for Car Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords