Round Aluminum Foil Sheets - Embossed/Tearplates/Stucco Aluminum Sheet/Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

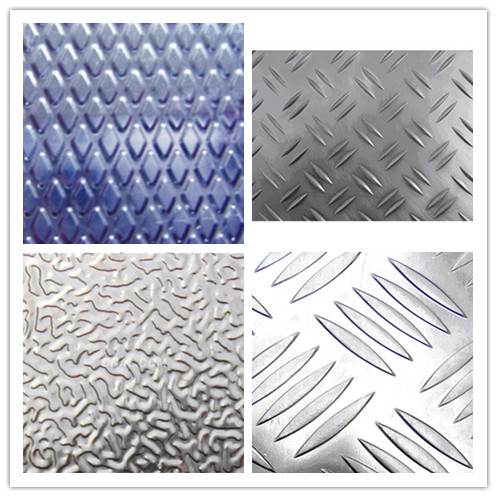

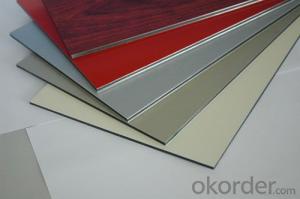

1.Structure of Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for construction:

Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for constructionis widely used for decorative purposes in construction, packing and appliance. Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for constructionis also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of the Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for construction

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for construction

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm-1500mm

4. Production of Aluminum Sheet/ Coil of Embossed/Tearplates/Stucco for construction

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: What is the tensile strength of aluminum?

- The tensile strength of aluminum varies depending on the specific alloy and temper, as well as the manufacturing process. However, on average, the tensile strength of aluminum ranges from around 70 to 700 MPa (megapascals). This makes aluminum a relatively strong material compared to other non-ferrous metals. It is important to note that the tensile strength can also be influenced by factors such as the thickness and shape of the aluminum component, as well as any heat treatment it has undergone. Therefore, it is always recommended to consult specific data sheets or engineering references for accurate and precise information regarding the tensile strength of a particular aluminum alloy.

- Q: Is it possible to use aluminum sheets as a material for interior wall decoration?

- <p>Yes, aluminum sheets can be used for interior wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications. Aluminum sheets are also easy to install and maintain, and they can be painted or finished in various ways to match different design styles. However, it's important to ensure proper installation and adherence to local building codes and regulations.</p>

- Q: Are 101 aluminum sheets suitable for chemical storage tanks?

- 101 aluminum sheets are not appropriate for chemical storage tanks. Aluminum, particularly 101 aluminum, lacks resistance against numerous chemicals, which may cause corrosion and potential leakage. To withstand the corrosive properties of chemicals, chemical storage tanks necessitate materials specifically engineered for this purpose, such as stainless steel or certain types of plastics. It is crucial to employ chemically resistant materials that guarantee the safety and integrity of the chemicals being stored.

- Q: What is the standard thickness of aluminum sheets used for constructing carports or garages?

- <p>The thickness of aluminum sheets commonly used for carports or garages typically ranges from 0.022 to 0.032 inches (0.56 to 0.81 mm). This range provides a balance between strength and cost-effectiveness. Thicker sheets offer greater durability and resistance to weathering, while thinner sheets are more affordable but may require more maintenance over time. The specific thickness chosen often depends on the design requirements, local weather conditions, and the intended lifespan of the structure.</p>

- Q: What are the different methods for joining aluminum sheets?

- There are several methods for joining aluminum sheets, depending on the specific application and desired outcome. Some of the common methods include: 1. Welding: Aluminum can be welded using various techniques such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW). TIG welding is commonly used for thin aluminum sheets, providing a strong and precise joint. MIG welding is suitable for thicker sheets and offers faster production rates. RSW involves passing an electric current through the sheets, melting the aluminum at the contact points, and then applying pressure to create a solid joint. 2. Mechanical Fasteners: Bolts, nuts, and screws can be used to join aluminum sheets together. They provide a strong and reliable connection that can be easily disassembled if needed. Rivets are another common mechanical fastening method, where a rivet gun is used to secure the sheets by deforming the rivet. 3. Adhesive Bonding: Specialized adhesives designed for aluminum bonding can be used to join sheets together. This method is often used when aesthetics are important, as it provides a clean and seamless appearance. Adhesive bonding also distributes the stress evenly across the joint, reducing the risk of localized stress concentration. 4. Clinching: Clinching is a cold joining process where a punch is used to deform the aluminum sheets, creating a mechanical interlock. This method is quick, cost-effective, and does not require additional materials like fasteners or adhesives. 5. Friction Stir Welding (FSW): FSW is a solid-state joining process that uses a rotating tool to generate friction between the aluminum sheets. The friction heats the material, making it pliable, and the rotating tool then stirs the softened material together to form a solid joint. FSW is particularly suitable for joining thicker aluminum sheets. Each joining method has its own advantages and disadvantages, and the choice depends on factors such as the desired strength, appearance, production rate, and the specific requirements of the application.

- Q: Can aluminum sheets be easily formed into different shapes?

- Aluminum sheets possess the capability to assume diverse forms with ease. Being an exceedingly flexible metal, aluminum can be effortlessly curved, stretched, and shaped without experiencing any cracks or fractures. This property renders aluminum a favored choice across numerous industries, ranging from automotive and aerospace to construction and manufacturing. Utilizing a variety of techniques such as bending, rolling, stamping, and deep drawing, aluminum sheets can be transformed into intricate and intricate designs. Moreover, owing to its lightweight nature, aluminum proves even more manageable during the formation process, requiring less force and energy. Consequently, aluminum sheets exhibit tremendous versatility and adaptability, rendering them exceptionally suitable for the creation of various shapes and structures.

- Q: How do aluminum sheets perform in terms of electrical conductivity?

- Aluminum sheets are known for their excellent electrical conductivity, ranking just below copper in terms of efficiency.

- Q: Are aluminum sheets suitable for solar reflectors?

- Certainly, solar reflectors can indeed make use of aluminum sheets. The construction of solar reflectors extensively relies on aluminum owing to its remarkable reflectivity and durability. By virtue of its reflective characteristics, aluminum effectively redirects sunlight onto solar panels or other solar equipment, thereby enhancing energy absorption. Moreover, aluminum is lightweight and resistant to corrosion, making it an excellent choice for outdoor use. Furthermore, its cost-effectiveness and ease of fabrication greatly contribute to its widespread adoption in the solar sector.

- Q: Can aluminum sheets be used for food display cases?

- Yes, aluminum sheets can be used for food display cases. Aluminum is a common material used in the food industry due to its durability, light weight, and resistance to corrosion. It is also easy to clean and maintain, making it suitable for displaying food in a hygienic and visually appealing way.

- Q: What is the difference between the alloy 1060H24 aluminum plate and the alloy 1100H24 aluminum plate?

- At present, most of the circulation in the market is 1050 and 1060 series. 1000 series aluminium plate to determine the minimum aluminum content in this series according to the amount of the last two Arabia figures, such as the 1050 series of the last two Arabia number 50, according to the international brand naming principles, content must reach 99.5% to the top for qualified products. China's aluminum alloy technology standard (gB/T3880-2006) is also clearly defined, 1050 aluminum content of 99.5%., the same reason, 1060 series aluminum plate aluminum content must reach more than 99.6%

Send your message to us

Round Aluminum Foil Sheets - Embossed/Tearplates/Stucco Aluminum Sheet/Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords