Laserable Aluminum Sheets Gold 1240mm x 1270mm Width PE and PVDF Color Coated Sublimation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 20-25days or according to the order quantity |

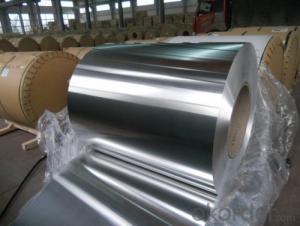

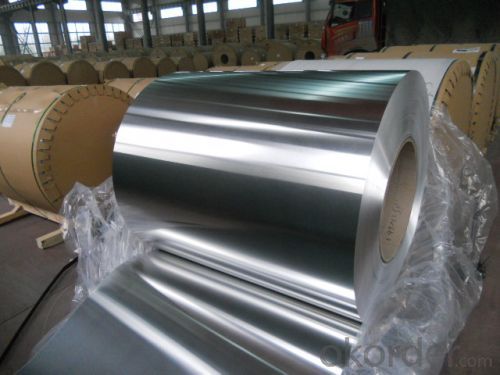

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

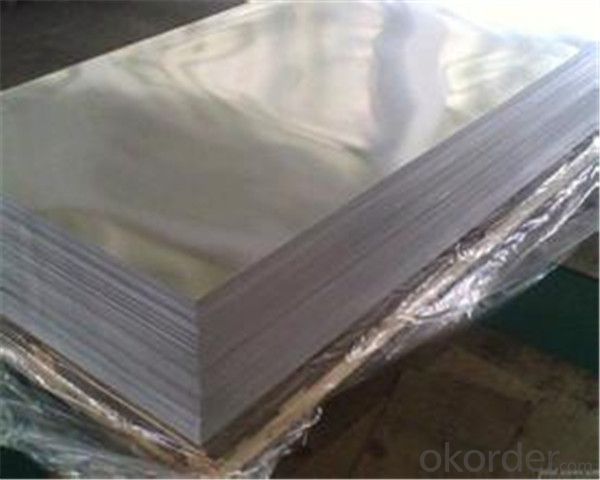

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

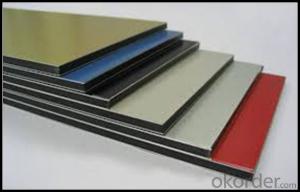

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Parameter

Product | Alloy | Temper | Thickness | Width | I.D(mm) | Application |

Aluminum Coil/Strip | 1050,1060,1070, 1100,1200,1235, 1145,3003,304, 3105,3A21, 8011 | O H12 H14 H16 H18 H22 H24 H26 | 0.2-8mm | 50-2400mm | 75,150 200,300 400,505 (as customers's request) | construction,decoration, automobile,electronic, machinery,boat construction, aeronatics&astronautics, cookware,packing etc. |

Application:

1) Radiator

2) Condenser

3) Insulation Material

4) Construction

5) Decoration

6) Advertisement and market applications

Photos

- Q: What are the rules and standards that govern the use of aluminum sheets in construction projects?

- <p>Yes, there are regulations regarding the use of aluminum sheets in construction. These regulations vary by country and region but generally cover aspects such as material standards, safety, and environmental impact. For instance, in the United States, the American Society for Testing and Materials (ASTM) provides standards for aluminum sheet materials. Building codes like the International Building Code (IBC) also specify requirements for the use of aluminum in construction. These regulations ensure that aluminum sheets meet certain strength, durability, and performance criteria. Compliance with these regulations is crucial for safety, structural integrity, and to obtain necessary permits and approvals for construction projects.</p>

- Q: Can 101 aluminum sheets be used in the production of consumer electronics?

- Yes, 101 aluminum sheets can be used in the production of consumer electronics. Aluminum is a lightweight and durable material that is commonly used in various electronic devices, including smartphones, laptops, and tablets. The specific grade of aluminum, such as 101, determines its properties and suitability for different applications.

- Q: Are the aluminum sheets suitable for manufacturing electrical enclosures?

- Yes, aluminum sheets are suitable for manufacturing electrical enclosures. Aluminum is a highly versatile and widely used material in the manufacturing industry, including for electrical enclosures. It offers several advantages that make it suitable for this application. Firstly, aluminum is lightweight yet strong, making it ideal for constructing enclosures that need to be durable while also being easily transportable and installable. Its strength-to-weight ratio is higher than many other metals, allowing for the creation of sturdy enclosures without adding unnecessary weight. Secondly, aluminum has excellent corrosion resistance. This is crucial for electrical enclosures as they are often placed in various environments where they may be exposed to moisture, humidity, or other corrosive elements. Aluminum's natural oxide layer provides a protective barrier against corrosion, ensuring the longevity and reliability of the enclosures. Additionally, aluminum is a good conductor of electricity, which is another important characteristic for electrical enclosures. It allows for efficient dissipation of heat generated by electrical components, preventing overheating and potential damage to the enclosed devices. Furthermore, aluminum is easily machinable and can be formed into various shapes and sizes. This flexibility allows manufacturers to customize the enclosures according to specific requirements, ensuring a perfect fit for the intended electrical components. Lastly, aluminum is a cost-effective material compared to other metals like stainless steel or copper. It offers a good balance between affordability and performance, making it an attractive choice for manufacturing electrical enclosures. In conclusion, aluminum sheets are indeed suitable for manufacturing electrical enclosures due to their lightweight, strength, corrosion resistance, electrical conductivity, machinability, and cost-effectiveness.

- Q: Can the aluminum sheets be used for manufacturing food packaging?

- Yes, aluminum sheets can be used for manufacturing food packaging. Aluminum is a popular choice for food packaging due to its non-reactive nature, resistance to corrosion, and ability to maintain the freshness and quality of food products.

- Q: Can 101 aluminum sheets be CNC machined?

- CNC machining is capable of processing 101 aluminum sheets, allowing for the creation of intricate and accurate cuts, holes, and shapes. This versatile and precise manufacturing process is commonly employed for aluminum materials. It involves computer-controlled machines that remove material from the sheets. The CNC machinability of 101 aluminum sheets is not restricted by their specific alloy designation. Nevertheless, to achieve optimal results, it is crucial to take into account factors like cutting parameters, tool selection, and feed rates when machining these sheets.

- Q: This question asks if aluminum sheets can be utilized for both exterior and interior purposes.

- <p>Yes, aluminum sheets can be used for both exterior and interior applications. They are popular for exterior use due to their durability, resistance to weather, and low maintenance requirements. For interior applications, aluminum sheets are valued for their lightweight, easy installation, and aesthetic appeal. They are commonly used in construction, automotive, and aerospace industries, among others. However, it's important to note that specific treatments or coatings may be necessary to enhance their performance in different environments.</p>

- Q: How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in its usability. A narrow thickness tolerance ensures uniformity and precision in the sheet's dimensions, allowing for consistent performance and ease of fabrication. It enables seamless integration into various applications, including construction, automotive, aerospace, and manufacturing industries. On the other hand, a wider thickness tolerance can limit its usability as it may result in irregularities, difficulty in fitting, and potential performance issues. Therefore, a tight thickness tolerance is crucial for ensuring optimal functionality and versatility of aluminum sheets.

- Q: Are aluminum sheets resistant to vibration?

- Yes, aluminum sheets are generally resistant to vibration due to their inherent strength and durability. The high stiffness-to-weight ratio of aluminum, along with its ability to dampen vibrations, makes it an ideal material for applications requiring vibration resistance.

- Q: Does it make any difference shiny side up, shiny side down when it comes to cooking with aluminum foil?

- The shiny side is slightly better reflector of heat. Face that side of the foil in the appropriate direction. To keep things cold, put the shiny side on the outside -- that will reflect incoming heat. To keep things warm, face the shiny side inward toward the hot food -- to reflect the heat that is trying to escape back into the food. Note that people often bake potatoes with the shiny side out -- that is because it makes for a better (prettier) presentation. In reality, baking them that way reflects the incoming heat on the outside, slightly slowing the cooking process. Of course, in reality, which side of the foil faces where makes little difference. It does make for lively conversation, though.

- Q: Are aluminum sheets suitable for storage tanks?

- Yes, aluminum sheets can be suitable for storage tanks depending on the specific requirements and purpose of the tank. Aluminum is a lightweight and corrosion-resistant material, making it an excellent choice for various storage applications. It offers good structural integrity and durability, with the ability to withstand harsh environments and weather conditions. Additionally, aluminum has a high strength-to-weight ratio, which means it can handle heavy loads while remaining relatively lightweight. However, it is important to consider the contents of the storage tank and consult with experts to ensure that aluminum is the appropriate material choice for the specific storage requirements.

Send your message to us

Laserable Aluminum Sheets Gold 1240mm x 1270mm Width PE and PVDF Color Coated Sublimation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords