Aluminum Profiles for Solar Panel Frame - Aluminium Profile Extrusion 6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

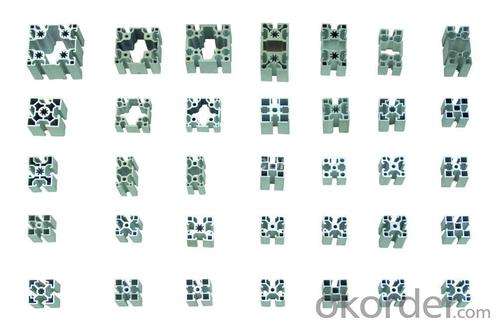

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What precautions should be taken while handling aluminum profiles to ensure safety?

- <p>When working with aluminum profiles, it's important to take several safety measures. Always wear appropriate personal protective equipment (PPE), including safety glasses to protect your eyes from flying debris, gloves to protect your hands, and a dust mask to prevent inhalation of dust particles. Ensure that the work area is well-ventilated to avoid inhaling aluminum dust. Use proper tools for cutting and shaping aluminum profiles to minimize the risk of injury. Keep the work area clean and free from clutter to prevent tripping hazards. Be cautious when handling sharp edges and ends of cut aluminum profiles. Lastly, be aware of the weight of the aluminum profiles to avoid back injuries when lifting.</p>

- Q: Is it possible to utilize aluminum profiles in the construction or structure of commercial buildings and factories?

- <p>Yes, aluminum profiles are commonly used in commercial buildings and factories due to their strength, durability, and lightweight properties. They are ideal for constructing frameworks, window and door frames, and support structures. The corrosion resistance of aluminum also makes it suitable for industrial environments where exposure to harsh chemicals or weather conditions is a concern. Additionally, aluminum profiles are easy to maintain and can be recycled, contributing to the sustainability of construction projects.</p>

- Q: Can aluminum profiles be used in agricultural greenhouse manufacturing?

- Yes, aluminum profiles can be used in agricultural greenhouse manufacturing. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for use in greenhouse structures. Aluminum profiles can be used to create the framework of the greenhouse, providing structural support and stability. Additionally, aluminum profiles can be easily customized and assembled, allowing for flexibility in greenhouse design. The use of aluminum profiles in agricultural greenhouse manufacturing helps to ensure a long-lasting and efficient structure for growing plants.

- Q: What is the maximum length of aluminum profiles available?

- The length of aluminum profiles that are available can differ based on the manufacturer and the specific product being considered. In broad terms, aluminum profiles can be made in lengths that range from a few inches to numerous feet. While certain manufacturers may provide standard lengths like 6 or 12 feet, others may possess the capacity to create custom lengths according to the customer's needs. To ascertain the maximum length possibilities for a particular aluminum profile, it is essential to consult with the manufacturer or supplier.

- Q: This question asks about the various surface treatments or finishes that can be applied to aluminum extrusions, which are shaped profiles made from aluminum.

- <p>Aluminum extrusions can be finished in several ways to enhance their appearance, durability, or functionality. Common finishes include anodizing, which provides a protective oxide layer; powder coating, offering a wide range of colors and textures; painting, which can be done electrostatically or by hand; polishing, resulting in a shiny, smooth surface; brushing, which creates a satin-like finish; and chromate conversion coating, which is a pretreatment for further painting or coating. Other finishes include wood grain transfer, which gives an aluminum surface a wood-like appearance, and various types of protective films or laminates. Each finish serves different purposes, from improving aesthetics to increasing corrosion resistance.</p>

- Q: Are aluminum profiles suitable for decorative applications?

- Indeed, decorative applications can benefit greatly from the use of aluminum profiles. This material, known for its versatility, provides numerous advantages in decorative contexts. To start with, aluminum profiles can be easily shaped and molded into various designs, offering endless possibilities for decorative applications. Designers have the freedom to extrude them into different shapes, sizes, and patterns, allowing for the creation of unique and visually pleasing decorative elements. Furthermore, aluminum profiles exhibit excellent durability and resistance to corrosion, making them suitable for both indoor and outdoor decorative applications. Thanks to their rust and weather resistance, decorative elements made from aluminum profiles can maintain their appearance for an extended period. Moreover, aluminum profiles can be finished in different ways to enhance their decorative appeal. Anodizing or powder-coating can be applied to the surface, adding color, texture, and protection. These finishing options allow for customization and the ability to harmonize the profiles with the overall design scheme. Additionally, aluminum profiles possess the advantageous combination of being lightweight and strong, facilitating their installation and handling during the decorative application process. This characteristic is especially valuable in situations where weight is a consideration, such as with suspended or wall-mounted decorative elements. Finally, it is worth noting that aluminum is an environmentally friendly and sustainable material. It is entirely recyclable, and the production process of aluminum profiles requires significantly less energy compared to other materials. By choosing aluminum profiles for decorative applications, one aligns with sustainable design principles and contributes to reducing the environmental impact. In conclusion, the versatility, durability, corrosion resistance, customization options, lightweight nature, and sustainability of aluminum profiles make them highly suitable for decorative applications. Whether it is for interior or exterior decorative elements, aluminum profiles offer a wide range of possibilities to enhance the aesthetic appeal of any space.

- Q: Are aluminum profiles suitable for use in the mining industry?

- The mining industry can benefit greatly from the use of aluminum profiles. Aluminum, known for its lightweight yet strong and durable qualities, offers numerous advantages in mining applications. One crucial advantage of aluminum profiles lies in their exceptional resistance to corrosion. In the mining industry, where equipment often faces harsh environmental conditions and exposure to chemicals, this corrosion resistance is vital. Aluminum profiles can endure moisture, chemicals, and other corrosive substances without deteriorating, ensuring long-lasting performance and minimizing maintenance costs. Another perk of aluminum profiles is their impressive strength-to-weight ratio. Compared to other metals commonly used in mining equipment, such as steel, aluminum is significantly lighter. This lightweight characteristic makes aluminum profiles easier to handle, transport, and install, resulting in saved time and reduced labor costs. Despite being lightweight, aluminum profiles are still robust enough to withstand the demanding conditions of the mining industry, making them a reliable choice for various applications. Furthermore, aluminum profiles offer excellent thermal conductivity. This property proves advantageous in mining operations involving heat-generating machinery or processes. Aluminum profiles efficiently dissipate heat, preventing equipment overheating and enhancing overall safety and productivity. Moreover, aluminum is a non-magnetic material, making it ideal for mining operations that require non-magnetic equipment. This characteristic ensures that aluminum profiles will not interfere with sensitive equipment or disrupt magnetic fields, maintaining the accuracy and reliability of mining processes. In summary, aluminum profiles are highly suitable for the mining industry due to their corrosion resistance, high strength-to-weight ratio, thermal conductivity, and non-magnetic properties. Integrating aluminum profiles into mining equipment can improve performance, reduce maintenance costs, and enhance overall efficiency in various mining applications.

- Q: This question asks if aluminum profiles can be utilized for constructing exterior walls or facades.

- <p>Yes, aluminum profiles can be used for exterior walls or facades. They are known for their durability, low maintenance, and resistance to weather conditions. Aluminum is lightweight, strong, and can be easily shaped into various designs, making it an ideal material for modern architecture. It also offers excellent thermal performance and can be combined with insulation to enhance energy efficiency. Additionally, aluminum profiles can be powder-coated or anodized to provide a protective finish and a wide range of color options, enhancing the aesthetic appeal of the building facade.</p>

- Q: How can I control the hardness of 6063 aluminum profile at 6-9 degrees?

- Classification: extension material, non heat treatment alloy and heat treatment alloy1.1 non heat treated alloys: pure aluminum - 1000 series, Al Mn alloy - 3000 series, Al Si alloy - 4000 series, Al Mg alloy - 5000 Series1.2 heat treatment of Al Cu Mg alloy alloy: 2000, aluminum magnesium silicon alloy - 6000 series aluminium zinc magnesium alloy - 7000.Two, alloy number: China's current general is the American Aluminum Association "Aluminium Association" numberExamples are as follows: 1070-H14 (pure aluminum)2017-T4 (heat treatment alloy)3004-H32 (non heat treated alloy)2.1 first digit: indicates the main addition of alloying elements1: pure aluminum2: the main alloy element added copper3: the main alloying elements are manganese or manganese and magnesium4: the main alloy element is added silicon5: the main alloying element is magnesium6: mainly add alloy elements for silicon and magnesium7: the main alloying elements are zinc and magnesium8: a new alloy that does not belong to the above alloy series2.2, second digits: an alloy that indicates the addition of alloying elements or impurities in the original alloy0: table alloy1: table original alloy by the first amendment2: table original alloy after second modifications2.3, third, and four digits:Pure aluminum: represents the original alloyAlloy: the designation of individual alloys"- >: the back of Hn or Tn indicates the condition of work hardening or the symbol of heat treatment state-Hn: indicating the symbol for non heat treated alloys-Tn: a symbol for heat treatment alloysHeat treatment of 2 aluminium and aluminium alloyA chain symbol: if the alloy element is added, it is not enough to meet the requirements, but still needs cold processing, quenching and agingTreatment and soft burning to obtain the required strength and performanceAs a result of quenching and tempering, the result of quenching and tempering is chain

- Q: Which is the highest price of aluminum profile 60616063?

- Generally speaking, 6061 of a little higher, but also depends on the quality, whether there is aging treatment, such as T6 status;6063, low silicon content, relatively soft, oxidation effect is better than 6061, suitable for appearance pieces, LED lamp holder, etc.; 6061, cutting performance is good, suitable for structural parts.

Send your message to us

Aluminum Profiles for Solar Panel Frame - Aluminium Profile Extrusion 6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords