Aluminium Coated Pet Film Metalizing Aluminum Mylar Mpet Film Moisture Proof Film

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated Pet film metalizing aluminum mylar mpet film Moisture proof film

Quality: 100% virgin pet

HS Code: 777309664

Processing Type: Multiple extrusion

Thinckness: 8mic-12mic

Main size: Width≤2350mm

Length 18000m/9000m/6000m

Usage: 1)PET food grade packing film2)PET printing film, pet release film

3)Metalized pet film,cpp/pet sealing film

4)Pet laminating film

Remark: All the indicators could be customized which includes the thickness, width, length, diameter.

Product Description

Aluminium coated Pet film metalizing aluminum mylar mpet film Moisture proof film

Metallized film (VMPET) is a silver color reflective film that is plated by aluminum layer on the film surface in vacuum condition which makes it high barrier resistance of oxygen and water vapor. It has glossy metallic appearance of an aluminum foil at a reduced weight and cost that can be widely used for packaging, decoration, insulation and electronics.

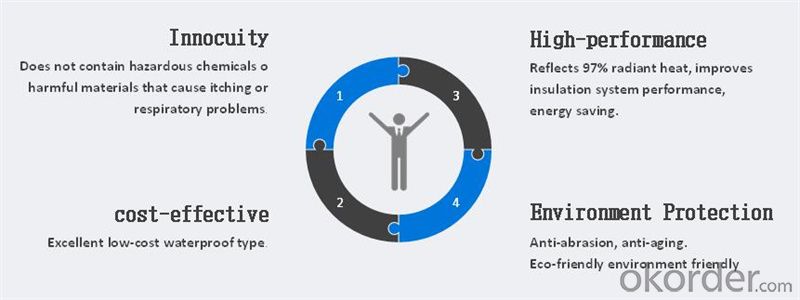

Our Advantage

Superiority of price: we control the whole process from raw materails purchasing to final product manufacturing.

Efficiency advantage: the fastest time of delivery is 7days.

Customization: all indicators could be customized which includes the thickness, width, length, diameter.

Device Show

- Q: Plastic film has eyes, how to make up?

- This method is suitable for greenhouses. Remove the damaged area first. According to the damaged area, cut a little larger than the broken film, and then stained with water, or use the natural water on the greenhouse, the film between the air row, the two film flat, hard to squeeze water beads.

- Q: Why do plastic films undergo prepress?

- And, because the gravure printing ink than flexo ink and color more, so the color can be restored more fullness and hierarchy, is more advantage.

- Q: What happens when the friction coefficient of PE plastic film becomes larger?

- The permeability of the adhesive to the inner surface affects the coefficient of friction on the surface of the base material, especially when the film is thin and the corona is over treated.

- Q: What is the specific weight of plastic film?

- This proportion has not, now known as the density of common units is g / cm3 (g/cm fand), kg / cubic meter (kg/dm tons / m3 (fand), fand t/m).

- Q: Can damp wood floors be made of plastic sheeting?

- Best not to use, so that the water can not evaporate out.

- Q: How to quickly remove the plastic film on the floor tiles?

- The mark left by the matches and the burning of the paper can be stained with a small amount of diluted oxalic acid solution with the waste toothbrush.

- Q: The plastic film on the TV screen doesn't need to be taken

- Protective film has a certain viscosity, when heated for a long time may cause difficult to tear off, affecting the appearance.Therefore, it is recommended that after the TV is bought and installed, the protective film on the edge will be torn off.

- Q: What film plastic is transparent and good for aging?

- Transmittance, carrying capacity, in general, 2 can meetAs for the leakage of water, 2FRP plate and PC plate are fixed by screws (of course there are general leak proof sealing measures) no problem, PC sun board in the U plate in the installation screw plate can completely penetrate the real waterproof leak.As for other materials, PMMA (plexiglass) anti-aging is not flattering

- Q: What is a water-soluble plastic packing film?

- On the degradation mechanism of polyvinyl alcohol, has water and biological degradation characteristics of two kinds of first, soluble in water to form a gel into the soil, increase soil mass viscosity and permeability and water retention, especially suitable for sand transformation. In the soil of PVA by soil bacteria isolated from a single cell (Pseudomonas - strain) decomposition. At least two kinds of system composed of commensal bacteria can degrade polyvinyl alcohol: an active bacteria bacteria is polyvinyl alcohol, the other one is to produce PVA active bacteria substances required for bacteria. The oxidation of secondary alcohols catalyzed by polyvinyl alcohol, then enzymatic hydrolysis by cutting the main chain of PVA, further oxidation degradation, eventually for CO2 and H2O. degradation

- Q: FFS plastic film bags are injection type?

- Tube film (blown film process) has become the best production method of FFS bag film products. FFS bag blown film technology is divided into single layer extrusion and multi layer extrusion technology according to its product form. Their production principle is basically the same, mainly equipment is different.

Send your message to us

Aluminium Coated Pet Film Metalizing Aluminum Mylar Mpet Film Moisture Proof Film

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords