030 Aluminum Coil - Aluminium Coated Coils for Cladding System and Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

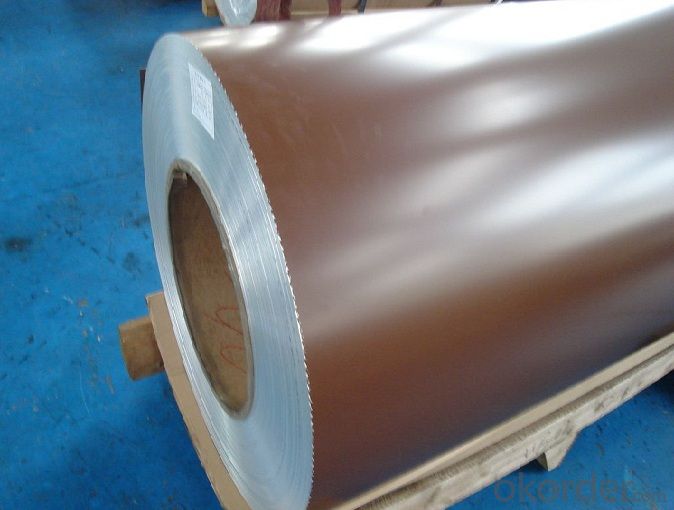

Aluminium Coated Coils for Cladding System and Roofing

l Product Information

| Alloy | 1050 1060 1100 3003 3004 3005 5005 8011 etc |

| Temper | H12, H14, H16, H18, H24, H26 |

| Thickness | 0.02mm - 1.2mm |

| Width | Standard width: 1240mm |

| Special width: 1300mm,1520mm,1570mm,1595mm | |

| Diameter | Standard dia:1200mm |

| Interior dia:150mm,405mm,505mm | |

| Weight | 2.5 T/coils, 3.0 T/coil |

| Coating | PE, PVDF,ACRYLIC |

| Surface | Embossed, mill finish, coated |

| Color | As to code RAL |

| Gloss | 10-90% (EN ISO-2813:1994) |

| Coating Thickness | PE:more than 18 micron |

| PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

| Coating Adhesion | 5J(en iso-2409:1994) |

| Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Flexibility (T-bend) | 2T |

| MEK resistance | more than 100 |

| Advantage | 1.High temperature resistant 2.Weathering resistance 3.Scrubbing resistant 4.Sound insulation 5.Acid or alkali proof 6. Fireproof 7.Light weight material is easy to construct and install |

| Out package | wooden splint with export standard |

| Application | ACP,wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels , etc |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received original L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What are the different coil slitting methods used for aluminum coils?

- There are several coil slitting methods used for aluminum coils, including rotary shear slitting, loop slitting, and simultaneous multi-blanking. These methods involve different techniques and equipment to precisely cut and separate aluminum coils into narrower strips or sheets. Each method has its advantages and is chosen based on factors like coil thickness, width, and desired output.

- Q: Are there any environmental considerations when using aluminum coils?

- When using aluminum coils, there are several environmental factors to consider. Firstly, the extraction of bauxite ore, which is necessary for aluminum production, can cause habitat destruction and soil erosion. Moreover, the extraction and refining of bauxite require a large amount of energy, leading to carbon emissions and climate change. In addition, the manufacturing of aluminum coils involves the use of various chemicals, such as lubricants, coolants, and solvents. If not properly managed, these chemicals can harm the environment by contaminating water sources and damaging ecosystems. Furthermore, the disposal of aluminum coils at the end of their lifespan can be problematic. Although aluminum is highly recyclable and can be melted down and reused, improper disposal can result in it ending up in landfills, where it takes hundreds of years to decompose. To address these environmental concerns, it is crucial to prioritize sustainable sourcing of aluminum. This could involve opting for recycled aluminum or choosing suppliers with responsible mining practices. Proper waste management and recycling of aluminum coils at the end of their lifespan are also essential to minimize the environmental impact. Additionally, improving energy efficiency during the production process and reducing the use of harmful chemicals can help mitigate the environmental footprint of using aluminum coils.

- Q: Is it possible to create a mobile phone stand or holder using aluminum coils?

- <p>Yes, you can use aluminum coils to make a mobile phone stand or holder. Aluminum is lightweight, durable, and easy to shape, making it a suitable material for such DIY projects. You can bend the aluminum coil into the desired shape to support your phone, either horizontally or vertically. Ensure the coil's diameter is appropriate to hold your phone securely without causing any damage. Remember to smooth any rough edges to prevent scratches on your phone.</p>

- Q: This question asks whether aluminum coils can be utilized in various forms and dimensions.

- <p>Yes, aluminum coils can be used in different shapes and sizes. They are versatile and can be cut, shaped, or rolled into various forms to suit specific applications. Aluminum's malleability allows it to be easily manipulated, making it suitable for a wide range of industries, including construction, automotive, and packaging. The size of aluminum coils can also vary, from small coils used for crafts to large ones used in industrial applications. The versatility of aluminum coils makes them a popular choice for many different projects and industries.</p>

- Q: How are aluminum coils used in solar panels?

- Aluminum coils are used in solar panels as part of the construction and structure of the panel. They are used to hold the solar cells in place and provide a sturdy framework for the overall structure. Additionally, aluminum coils help with heat dissipation and ensure efficient functioning of the solar panel by preventing warping or damage caused by temperature fluctuations.

- Q: Can aluminum coils be used in electrical cables?

- Electrical cables can indeed incorporate aluminum coils. Aluminum is widely utilized as a material for electrical conductors due to its exceptional electrical conductivity and comparatively lower cost when compared to copper. Its usage is particularly prominent in power transmission and distribution cables that necessitate long-distance transmission. Overhead power lines and underground cables often employ aluminum coils. However, it is crucial to acknowledge that aluminum possesses a lower tensile strength than copper, requiring careful design and manufacturing of the cables to ensure sufficient mechanical strength. Furthermore, achieving the same electrical performance with aluminum conductors necessitates larger cross-sectional areas compared to copper, potentially resulting in slightly larger cable sizes.

- Q: How do aluminum coils perform in corrosive environments?

- Due to their inherent properties and protective coatings, aluminum coils exhibit exceptional performance in corrosive environments. When exposed to air, aluminum forms a natural oxide layer on its surface, which acts as a protective barrier against corrosion. This oxide layer displays high resistance to various corrosive agents, including saltwater, acids, and atmospheric pollutants. Moreover, aluminum coils can receive additional protection through diverse coatings and treatments, further enhancing their resistance to corrosion. These protective coatings can be organic, such as paint or lacquer, or inorganic, like anodizing or chemical conversion coatings. The combination of aluminum's natural oxide layer and supplementary protective coatings makes aluminum coils highly reliable and durable in corrosive environments. This corrosion resistance is especially advantageous in industries such as marine, chemical processing, and coastal applications, where exposure to saltwater or aggressive chemicals is commonplace. In addition, aluminum coils are lightweight, contributing to their versatility and ease of installation, making them suitable for a wide range of corrosive environments. This lightweight property also aids in reducing transportation costs and energy consumption during the installation process. In conclusion, aluminum coils are well-suited for corrosive environments due to their inherent corrosion resistance and the availability of protective coatings. Their durability, lightweight nature, and resistance to corrosion make them the ideal choice for numerous industries and applications, where longevity and performance are essential considerations.

- Q: What are the weight savings achieved by using aluminum coils?

- The weight savings achieved by using aluminum coils can vary depending on the specific application, but generally speaking, aluminum coils are significantly lighter than traditional materials such as steel. On average, aluminum coils can provide weight savings of around 50% or more compared to steel coils. This weight reduction is especially beneficial in industries like automotive, aerospace, and construction, where lighter materials can contribute to improved fuel efficiency, increased load capacity, and enhanced overall performance.

- Q: Are there any fire safety considerations when using aluminum coils?

- When using aluminum coils, fire safety considerations must be taken into account. This is because aluminum is a highly flammable material, and if not handled and installed correctly, it can present a fire hazard. To minimize the risk of fire, it is crucial to install the aluminum coils in a manner that reduces the chance of fire, such as using appropriate insulation and avoiding direct contact with other flammable substances. Furthermore, regular maintenance and inspections should be conducted to detect any potential problems or signs of overheating that may result in a fire. Adhering to fire safety protocols and guidelines, like having a fire extinguisher nearby and ensuring adequate ventilation, can also assist in mitigating the fire risk associated with aluminum coils.

- Q: i dont want aluminum cookware, but how about a stainless steel set with an aluminum core. Is this the same as aluminum pots and pans? Thanks.

- The aluminum is encased in the stainless steel, usually as a thick disk in the bottom. It is an excellent conductor of heat and holds the heat well once it gets hot. All you see is the stainless, none of the aluminum because it's between two layers of stainless in the bottom of the pots. You are right, you don't want food cooked in straight aluminum, some metal taste can transfer to certain foods. That won't happen with stainless.

Send your message to us

030 Aluminum Coil - Aluminium Coated Coils for Cladding System and Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords