027 Aluminum Coil for Aluminium Profile Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coated Coil for Aluminium Profile Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coated Coil for Aluminium Profile:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

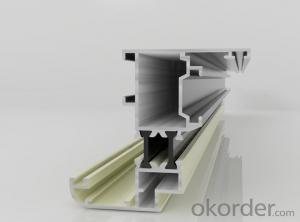

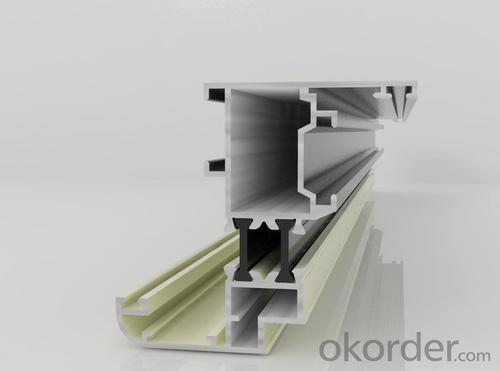

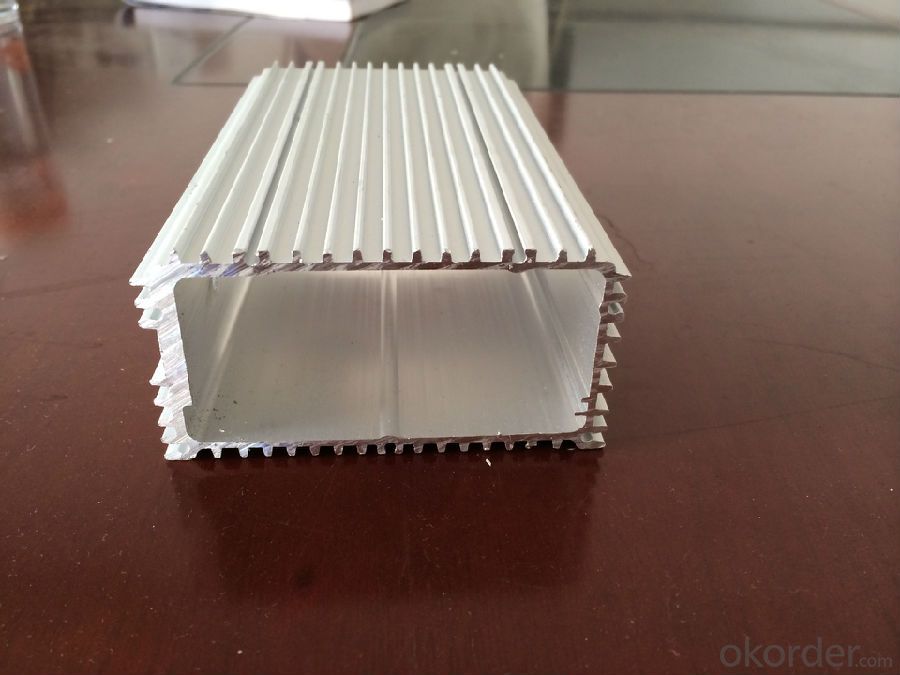

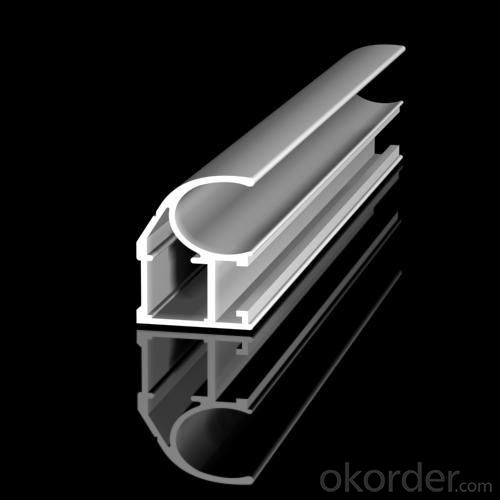

Images of the Aluminium Coated Coil for Aluminium Profile:

Aluminium Coated Coil for Aluminium Profile Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do aluminum coils compare to other types of coils (e.g., copper)?

- Aluminum coils generally have a lower cost compared to copper coils, making them a more budget-friendly option. However, copper coils tend to have better heat transfer properties and are more durable, which can result in improved system performance and longer lifespan. The choice between aluminum and copper coils depends on factors such as budget, desired efficiency, and specific application requirements.

- Q: Why is the aluminum roll upset?

- Mainly in the aluminum slitting process, for various reasons, does not meet the standards and specifications of products, can be used to roll the machine from the new trimming and slitting, winding up to meet customer needs of product specifications

- Q: What are the typical delivery options for aluminum coils?

- The typical delivery options for aluminum coils include shipping via truck, rail, or ocean freight. Additionally, local pickup may also be available for customers located near the manufacturing facility or distribution center.

- Q: This question asks for methods to determine whether an aluminum coil is new or old.

- <p>To determine if an aluminum coil is new or old, you can look for several signs: 1. Surface appearance: New coils typically have a clean, smooth surface without scratches or discoloration. 2. Packaging: New coils are usually well-packaged and protected. 3. Manufacturing date: Check for any labels or markings that indicate the manufacturing date. 4. Quality of the material: New coils should have consistent thickness and no signs of corrosion or wear. 5. Performance: New coils should perform as expected without any issues. If you're still unsure, consider consulting with a professional or the supplier for more information.</p>

- Q: How are aluminum coils transported and delivered?

- Aluminum coils are typically transported and delivered using specialized transport vehicles equipped with coil racks or cradles that securely hold the coils in place. These vehicles can be trucks, trains, or ships, depending on the distance and mode of transportation. The coils are usually loaded onto the transport vehicle using cranes or forklifts, ensuring proper handling and minimizing damage. Once at the delivery destination, the coils are carefully unloaded using similar equipment and delivered to their final destination, such as a manufacturing facility or warehouse.

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Yes, aluminum coils can be used in the production of aircraft fuel tanks. Aluminum is a commonly used material in the aerospace industry due to its lightweight, strong, and corrosion-resistant properties. It is an ideal choice for fuel tanks as it can effectively withstand the harsh conditions and requirements of aircraft operations.

- Q: Why does fillet appear when rolling aluminum coil?

- How thick and wide is it when there is such problem? Which is the rolling pass? And what is the type of the rolling mill? The simple 4 rollers or CVC and HC rolling mill with roller control. Does the filler appear in rolling or out of roller? Different thickness will lead to different analysis.

- Q: I HEARD THAT ALUMINUM POWDER TIGHTEN YOUR VAGINA BUT WHERE DO I BUY IT AND HAVE ANY ONE HEARD OF BEYDARY PILLS, I HEARD THEY TIGHTEN YOUR VAGINA ALSO AND WHERE CAN I BUY THEM

- You can buy aluminum powder online but I assure you completely it will not help. And aluminum can be toxic if it gets into your bloodstream in too large an amount. I also think you must mean bayberry as that is used to reduce bleeding and discharge in the vaginal area. But it doesn't tighten anything. There isn't anything you can put on there to change it.. do kegel exercises is your real only hope.

- Q: How are aluminum coils processed for specific surface coatings?

- Aluminum coils are processed for specific surface coatings through a series of steps that involve cleaning, pre-treatment, application of the coating, and curing. Firstly, the aluminum coils are thoroughly cleaned to remove any dirt, grease, or other contaminants that may hinder the adhesion of the coating. This is usually done through a combination of chemical cleaning agents, rinsing, and sometimes mechanical methods. After cleaning, the coils undergo a pre-treatment process. This step prepares the surface of the aluminum for optimal adhesion of the coating. Depending on the specific coating requirements, the pre-treatment can involve chemical etching, conversion coating, or both. Chemical etching creates a rough surface that enhances the bond between the aluminum and the coating, while conversion coating forms a thin layer that improves corrosion resistance and adhesion. Once the pre-treatment is complete, the specific surface coating is applied onto the aluminum coils. This can be done through various methods such as coil coating, spray coating, or electrostatic coating. Coil coating is a common technique where the coil is continuously fed through a coating line where the coating material is applied evenly and precisely onto the surface. After the coating is applied, the aluminum coils are cured to ensure the coating properly adheres and hardens. Curing can be done through heat, where the coated coils are passed through an oven or furnace at a specific temperature and time to promote cross-linking and curing of the coating material. Alternatively, some coatings may require UV curing, where the coated coils are exposed to ultraviolet light to achieve the desired curing process. Overall, the process of processing aluminum coils for specific surface coatings involves cleaning, pre-treatment, coating application, and curing. This ensures that the coils are properly prepared and coated to meet the desired surface properties and performance requirements.

- Q: Can aluminum coils be used for electronic enclosures?

- Yes, aluminum coils can be used for electronic enclosures. Aluminum is a commonly used material for enclosures due to its lightweight, durability, and excellent electrical conductivity. Additionally, aluminum coils can be easily formed and shaped to fit specific electronic components, making them a suitable choice for electronic enclosures.

Send your message to us

027 Aluminum Coil for Aluminium Profile Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords