Raw Aluminum Sheets - Aluminium Ceiling Panels for Sale in China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Ceiling Panels for Sale in China Supplier

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminium Ceiling Panels for Sale in China Supplier

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

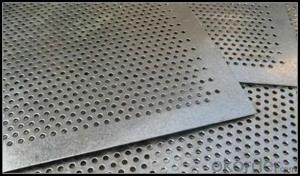

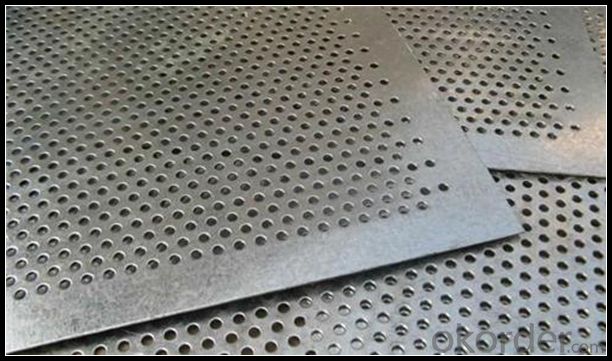

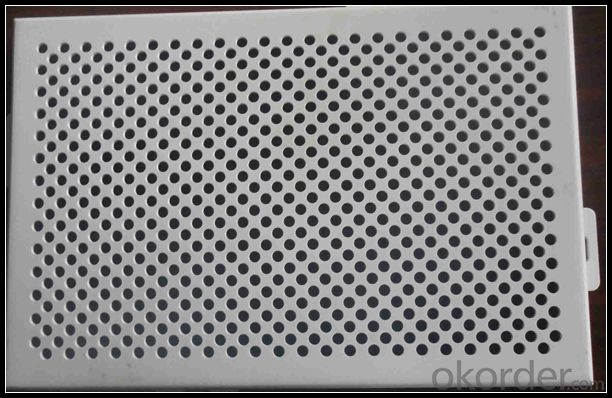

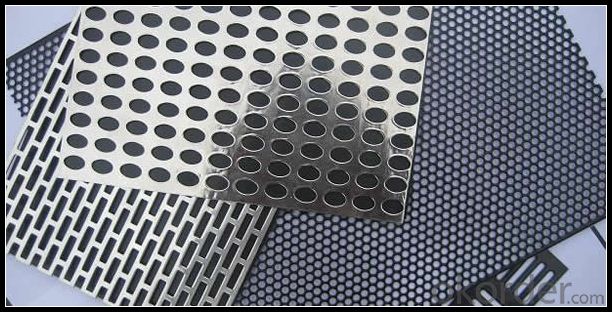

3. Aluminium Ceiling Panels for Sale in China Supplier Images

4.Specification of Aluminium Ceiling Panels for Sale in China Supplier

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Q. Calculate the number of aluminium ions present in 0.051 g of aluminium oxide.( Hint: The mass of an ion is the same as that of an atom of the same element. Atomic mass of Al = 27 u) Please Explain each and every step!!!Thankx..A lot !!

- The formula for aluminium oxide is Al2O3 Its molecular weight is 2*27+3*16= 54+48 =102 Now, 102g of Al2O3 contains 2*6.023*10^23 number of Al ions so 1g contains (2*6.023*10^23)/102 number of Al ions so 0.051g Al2O3 contain (2*6.023*10^23)/102 *0.051 number of Al ions which is equal to 6.023*10^23*10^-3 = 6.023*10^20 number of Al ions(Answer)

- Q: Are aluminum sheets suitable for electrical connectors?

- Indeed, electrical connectors can be effectively made using aluminum sheets. Aluminium, being a metal with high conductivity, is an ideal option for facilitating the flow of electric current. Its low electrical resistance enables the efficient transmission of electricity. Moreover, aluminum is renowned for its lightweight properties, resistance to corrosion, and affordability, rendering it a favored choice for electrical connectors across diverse sectors like automotive, aerospace, and electronics. Nevertheless, it should be emphasized that when aluminum connectors are utilized alongside dissimilar metals, extra precautions might be necessary to avert the occurrence of galvanic corrosion.

- Q: Can aluminum sheets be used for HVAC systems?

- Yes, aluminum sheets can be used for HVAC systems. Aluminum is a popular choice for HVAC applications due to its excellent corrosion resistance, lightweight properties, and thermal conductivity. It is commonly used for manufacturing air conditioner coils, heat exchangers, ductwork, and other components in HVAC systems.

- Q: Are the aluminum sheets suitable for manufacturing traffic signs?

- Yes, aluminum sheets are highly suitable for manufacturing traffic signs. Aluminum is a durable, lightweight, and corrosion-resistant material, making it ideal for outdoor applications. It can withstand harsh weather conditions and remains visible for a long time. Additionally, aluminum is easy to work with, allowing for easy customization and installation of traffic signs.

- Q: What are the different methods of surface printing aluminum sheets?

- Aluminum sheets can be surface printed using various methods, each with its own advantages and applications. Some commonly used techniques include: 1. Screen Printing: This technique involves using a mesh screen with a stencil to transfer ink onto the aluminum sheet. It offers precise printing and vibrant colors, making it suitable for signage, labels, and decorative purposes. 2. Digital Printing: Advancements in technology have made digital printing popular for aluminum sheet printing. It directly prints the design onto the sheet using inkjet technology, offering high detail and a wide range of colors for customized and complex designs. 3. Offset Printing: This versatile method transfers the design from a plate onto a rubber blanket, which is then pressed onto the aluminum sheet. It provides consistent and accurate printing results, often used for packaging, labels, and large-scale printing. 4. Flexographic Printing: This cost-effective method uses flexible relief plates to press the desired design onto flexible materials like aluminum sheets. It is suitable for large-scale production and commonly used for packaging materials and labels. 5. Gravure Printing: Also known as rotogravure printing, this method uses engraved cylinders to transfer ink onto the aluminum sheet. It is known for its high quality and ability to reproduce fine details, often used for high-end packaging, decorative items, and high-resolution images. 6. Embossing: Although not a printing method, embossing is a popular technique for creating raised designs on aluminum sheets. It can be done mechanically or through heat processes, resulting in a three-dimensional effect. Embossed aluminum sheets are used for decorative purposes, architectural applications, or to enhance surface grip. These are just a few of the methods available for surface printing aluminum sheets. The choice of method depends on factors such as design requirements, level of detail, quantity, budget, and intended application.

- Q: What is the cost of aluminum sheet compared to other metals?

- The cost of aluminum sheet is generally lower compared to other metals such as steel or titanium.

- Q: Are aluminum sheets suitable for marine applications?

- Indeed, aluminum sheets prove to be a fitting option for marine applications. Owing to its exceptional resistance to corrosion and durability in marine settings, aluminum emerges as a widely employed material in the maritime sector. Notably, its lightweight yet robust nature renders it an ideal selection for diverse purposes, encompassing boat construction, ship hulls, decks, and other marine structures. Moreover, aluminum boasts a commendable strength-to-weight ratio, thereby enhancing fuel efficiency and reducing operational expenses. Its capacity to endure the harsh conditions of saltwater, coupled with its minimal maintenance requirements, further solidifies its popularity in marine applications. All in all, aluminum sheets serve as a dependable and efficient material for employment in the marine industry.

- Q: This question asks if there are distinctions among various coatings applied to aluminum sheets.

- <p>Yes, there are significant differences between different types of coatings on aluminum sheets. These differences can include the purpose of the coating, such as for corrosion resistance, decorative effects, or enhanced durability. The materials used for the coatings can also vary, with options like anodizing, powder coating, or paint. Each type of coating has unique properties, such as resistance to weather, chemicals, or UV rays, and they can affect the surface appearance, weight, and cost of the aluminum sheet. The choice of coating often depends on the specific application and environmental conditions the aluminum sheet will be subjected to.</p>

- Q: combines with oxygen with an atomic weight of 16, to form the compound aluminum oxide, how much oxygen would be required to react completely with 54g of aluminum?

- Well, Al2O3 is the formula for aluminum oxide So you have 2 moles of Al, so you need 3 moles of O which is 1.5 moles of O2 So the answer is 48g

- Q: Are aluminum sheets magnetic?

- Aluminum sheets lack magnetic properties and do not exhibit any attraction or interaction with magnets. This is due to the absence of magnetic elements like iron or nickel in aluminum, making it a non-magnetic metal.

Send your message to us

Raw Aluminum Sheets - Aluminium Ceiling Panels for Sale in China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords