China Pvdf Coated Aluminum Coil - Aluminium CC DC Cold Rolling Coil and Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description

Aluminium is a relatively soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. A fresh film of aluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa.

2. Specification

ALUMINIUM COIL

ALLOY: AA1***

AA3***

AA5***

TEMPER: H14 H16 H18 H22 H24 H26 H32 O/F

THICKNESS:0.03MM-3.0MM

WIDTH: 30MM-1700MM

COATING: PE(POLYESTER),PVDF,EPOXY

STANDARD: GB/T 17748-1999

3. Advantage

Best Price!

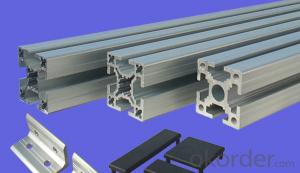

4. Pictures

5. FAQ

1)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2)How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: In my line of work I see aluminum ground lugs, bonding nuts and straps and also neutral bars eat copper up, especially when exposed to the elements. I know how galvanic reaction works between elements under current load, but my question is why do aluminum and copper seem to hate each other more than any other? And, why would they still be required in usage together per NEC code?

- that's a single alternative reaction. The aluminum and the copper swap places, yielding copper and aluminum sulfate. Please notice: the 1st answer describes a chemical equation with nitrate, no longer sulfate. otherwise, this is the perfect format.

- Q: Why the end of the aluminum coil will have a yellow spot?

- The reason may be that the manufacturer is not cleaned, and must be carefully cleaned before coating, or there may be paint fall off phenomenon.

- Q: What is the role of aluminum coils in HVAC systems?

- The role of aluminum coils in HVAC systems is crucial for the efficient functioning of the system. Aluminum coils are an essential component of the air conditioning unit as they are responsible for transferring heat between the indoor and outdoor environments. When the air conditioning unit is in cooling mode, the aluminum coils act as evaporator coils. They help in absorbing heat from the indoor air, thus cooling it down. The warm air from the room passes over the cold aluminum coils, and the heat is transferred to the refrigerant flowing through the coils. This process cools the air and removes moisture, resulting in the desired cooling effect. In heating mode, the aluminum coils function as condenser coils. They receive the hot refrigerant from the compressor and transfer the heat to the surrounding air. This hot air is then distributed throughout the building, providing warmth during colder weather. Aluminum coils are preferred in HVAC systems due to their excellent heat transfer properties and resistance to corrosion. They are lightweight, durable, and have a high thermal conductivity, allowing for efficient heat exchange. Moreover, aluminum coils are more environmentally friendly compared to other materials like copper, as they are easier to recycle. Regular maintenance and cleaning of the aluminum coils are necessary to ensure optimal performance and prevent any airflow restrictions caused by dust, dirt, or debris buildup. Neglecting coil maintenance can lead to reduced cooling or heating capacity, decreased energy efficiency, and potential system breakdowns. Overall, aluminum coils play a vital role in HVAC systems by facilitating the heat transfer process, enabling efficient and effective temperature control in both cooling and heating modes, and contributing to the overall comfort and functionality of the system.

- Q: What are the maintenance requirements for aluminum coils?

- To ensure optimal performance and longevity, aluminum coils require regular cleaning and inspection. It is recommended to clean the coils at least once a year, or more frequently in areas with high pollution or corrosive environments. Use a mild detergent or coil cleaner along with a soft brush or cloth to remove any accumulated dirt, dust, or debris from the coils' surface. Regular inspection is also crucial to identify any signs of damage, corrosion, or leakage. Bent fins, dents, or corrosion should be promptly addressed to prevent further harm and maintain coil efficiency. If there are any indications of leakage, it is essential to have a professional technician inspect and repair the coils to prevent potential refrigerant leaks. Additionally, it is advisable to keep the area around the coils clean and free from obstructions that may hinder airflow, such as leaves, plants, or debris. This will ensure proper airflow and prevent the coils from overworking, which can result in inefficiency and possible damage. In conclusion, maintaining aluminum coils involves regular cleaning, inspection for damage, corrosion, or leakage, and keeping the surrounding area clear for optimal performance and longevity. By following these maintenance practices, you can ensure the efficient functioning of the aluminum coils and extend their lifespan.

- Q: Some properties of aluminum are summarized in the following list.normal melting point 658°C heat of fusion 3.95 kJ/g normal boiling point 2467°C heat of vaporization 10.52 kJ/g specific heat of the solid 0.902 J/g°C Calculate the quantity of energy required to heat 1.58 mol of aluminum from 33°C to its normal melting point? In KJCalculate the quantity of energy required to melt 1.02 mol of aluminum at 658°C? In KJCalculate the amount of energy required to vaporize 1.02 mol of aluminum at 2467°C? In KJ

- Calculate the quantity of energy required to heat 1.58 mol of aluminum from 33°C to its normal melting point in KJ- 1.58 mol x 26.98 g/mol x 0.902 J/g°C x (658 - 33)°C x 1 kJ/1000 J = 24.03 kJ Calculate the quantity of energy required to melt 1.02 mol of aluminum at 658°C In KJ- 1.02 mol x 26.98 g/mol x 3.95 kJ/g = 108.7 kJ Calculate the amount of energy required to vaporize 1.02 mol of aluminum at 2467°C In KJ- 1.02 mol x 26.98 g/mol x 10.52 kJ/g = 289.5 kJ

- Q: The user is asking if it's possible to recycle old aluminum coils to create new ones.

- <p>Yes, you can recycle old aluminum coils into new ones. Recycling aluminum is a highly efficient process, and it's very common in the industry. Aluminum has one of the highest recycling rates among metals due to its value and the energy savings associated with recycling compared to producing new aluminum from raw materials. When you recycle aluminum, it can be melted down and reformed into new coils or other products without losing its properties. This process helps conserve resources and reduces environmental impact.</p>

- Q: What are the safety regulations that need to be followed while using aluminum coil?

- <p>Yes, there are safety regulations for using aluminum coil. These include ensuring proper ventilation to prevent the buildup of aluminum dust, which can be a fire hazard. Protective equipment such as gloves and eyewear should be worn to avoid skin and eye contact with the material. Additionally, it's crucial to follow guidelines for handling and storing aluminum coils to prevent accidents, such as ensuring they are not damaged or exposed to extreme temperatures. Compliance with local and industry-specific safety standards is also essential to maintain a safe working environment.</p>

- Q: Can aluminum coils be used in wastewater treatment plants?

- Yes, aluminum coils can be used in wastewater treatment plants. Aluminum coils are commonly used in the construction of heat exchangers, which are essential components in wastewater treatment plants. Heat exchangers are used to transfer heat from the wastewater to the treatment process, helping to optimize the treatment efficiency and reduce energy consumption. Aluminum coils are preferred in some cases due to their excellent thermal conductivity, lightweight, and resistance to corrosion, making them suitable for the harsh environment of wastewater treatment plants. Additionally, aluminum coils are cost-effective and have a long lifespan, making them a reliable choice for use in wastewater treatment facilities.

- Q: I am trying to electropolish the surface of a 3003 aluminum sample to analyze in the SEM. I was wondering if anyone knew what electrolyte and electropolishing paramaters work for this alloy. So far I have used phosporic+ethanol+water at 50V for 2 minutes with minimal success.

- Aluminium needs deoxidizing also called as desmutting after electropolishing. This is done in a hot chromic acid bath for nearly for 5 minutes.

- Q: Are aluminum coils prone to corrosion?

- Aluminum coils have a tendency to corrode, as aluminum is a reactive metal that readily develops a protective oxide layer upon contact with oxygen. Nevertheless, certain environmental elements like moisture, salt, or corrosive substances can compromise this oxide layer. Consequently, corrosion may gradually manifest on the surface of aluminum coils. To mitigate this risk, regular maintenance and appropriate care, such as cleaning and applying protective coatings, can be beneficial.

Send your message to us

China Pvdf Coated Aluminum Coil - Aluminium CC DC Cold Rolling Coil and Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords