Painted Aluminum Sheets 5x10 - Aluminium Alloy and Sheet for Building Industrial

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Alloy and Aluminium Sheet for Building Industrial Description:

Aluminium Alloy and Aluminium Sheet for Building Industrial is mainly used in billboards, building exterior decoration, bus body, high rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves and so on.

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc

2.Main Features of Aluminium Alloy and Aluminium Sheet for Building Industrial :

PVC or paper inter to protect the surface

Totally free from defects like white rust, oil patches

High Quality

Competitive Price

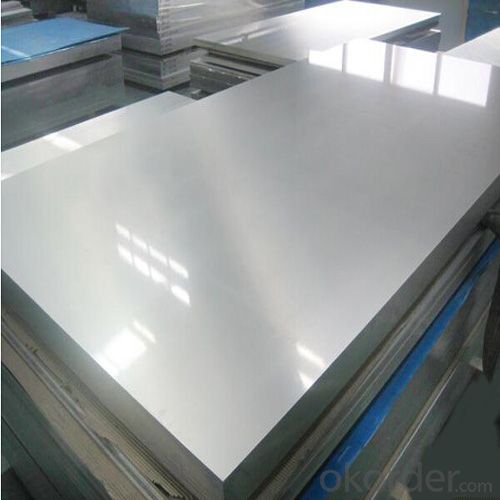

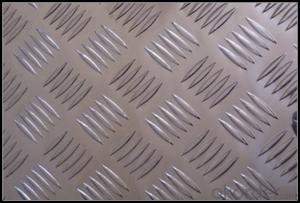

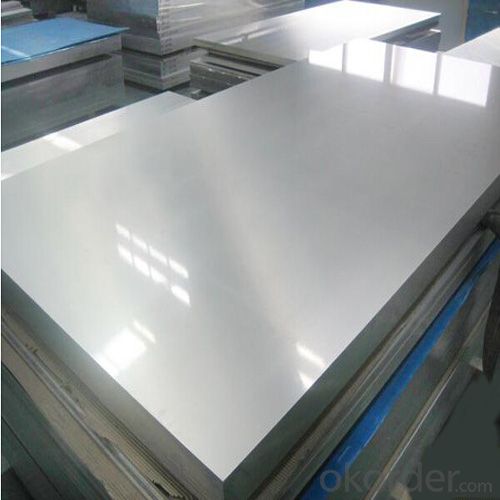

3.Aluminium Alloy and Aluminium Sheet for Building Industrial Images:

4. Aluminium Alloy and Aluminium Sheet for Building Industrial Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: This question asks for methods to prevent rusting on aluminum sheets during the installation process.

- <p>To prevent rusting on aluminum sheets during installation, ensure that the aluminum is of high quality and free from impurities. Keep the surface clean and dry at all times, avoiding contact with corrosive materials. Use appropriate protective coatings or sealants that are compatible with aluminum. Avoid scratches or dents that can expose the metal to moisture. Store aluminum sheets in a dry place before installation. During installation, handle the sheets carefully to avoid damage. Regularly inspect and maintain the aluminum sheets to catch any signs of corrosion early.</p>

- Q: Do 101 aluminum sheets have any specific insulation properties?

- No, 101 aluminum sheets do not have any specific insulation properties. Aluminum is a good conductor of heat and electricity, which means it does not provide insulation against heat or cold. However, aluminum sheets can be used as a reflective surface to reflect heat or light. To provide insulation, additional materials such as foam or fiberglass can be added along with the aluminum sheets.

- Q: What are the different types of finishes used for decorative aluminum sheet?

- Decorative aluminum sheet can be enhanced and protected with various types of finishes. Here are some of the most common finishes available: 1. Mill finish: This is the standard finish when aluminum sheets come directly from the mill. It has a smooth, shiny appearance without any additional treatments or coatings. 2. Anodized finish: By undergoing an electrochemical process, a durable, corrosion-resistant layer is created on the aluminum surface. Anodized finishes can be clear or colored, giving the sheet a decorative, matte look. 3. Brushed finish: Also referred to as satin finish, this finish involves brushing the aluminum sheet with a fine abrasive material to produce fine lines or scratches. It results in a textured, non-reflective surface that conceals imperfections. 4. Polished finish: This finish includes polishing the aluminum sheet using a series of abrasive materials to achieve a smooth, reflective surface. It creates a shiny, mirror-like appearance, often utilized for decorative purposes. 5. Painted finish: Aluminum sheets can be coated with various types of paints to achieve different colors and finishes. These coatings can be applied through methods like powder coating, liquid painting, or coil coating, offering both decorative and protective advantages. 6. Embossed finish: This type of finish involves pressing a pattern or design onto the aluminum sheet, creating a three-dimensional surface. Embossed finishes can vary in depth and detail, adding texture and visual interest to the sheet. These examples demonstrate the variety of finishes available for decorative aluminum sheet. Each finish offers its own distinct appearance and benefits, allowing for a wide range of design options.

- Q: What is the price range of aluminum sheets?

- The cost of aluminum sheets can fluctuate due to multiple elements, including the sheet's dimensions, thickness, and quality, as well as the supplier and market circumstances. Typically, the price of aluminum sheets can vary between approximately $0.50 and $5 per square foot. Thinner sheets or lower-quality aluminum tend to occupy the lower end of this price spectrum, while thicker sheets or higher-quality aluminum tend to fall on the higher end. It is advisable to compare prices among various suppliers to secure the most advantageous offer.

- Q: Are aluminum sheets non-magnetic?

- Yes, aluminum sheets are non-magnetic. Aluminum is not a ferromagnetic material, which means it does not have strong magnetic properties. It is classified as a paramagnetic material, which means it has a weak response to magnetic fields. Therefore, aluminum sheets do not attract or hold a magnet.

- Q: Are aluminum sheets flammable?

- No, aluminum sheets are not flammable. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and is known for its non-combustible properties. It does not burn or support combustion, making it a preferred choice for various applications where fire resistance is important, such as in the construction industry.

- Q: What are the dimensions of standard aluminum sheets?

- Standard aluminum sheets typically have dimensions of 4 feet by 8 feet. However, it's important to note that aluminum sheets come in various thicknesses, ranging from thin gauge sheets to thicker plates. The thickness of standard aluminum sheets can vary from 0.025 inches to 0.25 inches or more. Additionally, aluminum sheets can be cut and customized to different sizes and shapes based on specific project requirements.

- Q: Can the aluminum sheets be used for manufacturing heat shields?

- Yes, aluminum sheets can be used for manufacturing heat shields. Aluminum is known for its excellent thermal conductivity and high heat resistance. It is commonly used in various industries, including automotive and aerospace, for manufacturing heat shields. Aluminum sheets can effectively reflect and dissipate heat, making them an ideal material for this purpose. Additionally, aluminum is lightweight and corrosion-resistant, making it a practical choice for heat shield manufacturing.

- Q: Are the aluminum sheets suitable for manufacturing consumer goods?

- Indeed, consumer goods can be manufactured using aluminum sheets. This material possesses qualities of being lightweight, durable, and easily moldable, allowing for the creation of diverse shapes and sizes. Its remarkable resistance to corrosion renders it perfect for items that may face moisture or harsh environments. Moreover, aluminum stands out as an environmentally conscious choice due to its high recyclability. The attractiveness, sturdiness, and adaptability of aluminum sheets render them an exceptional choice for producing consumer goods, including kitchen utensils, appliances, furniture, packaging materials, and automotive components.

- Q: Are 101 aluminum sheets suitable for food-grade applications?

- Yes, 101 aluminum sheets are suitable for food-grade applications. 101 aluminum is a commercially pure alloy with excellent corrosion resistance and good formability. It has a low chemical reactivity, which means it does not react with acidic or alkaline foods, making it safe for use in food-grade applications. Additionally, 101 aluminum sheets can be easily cleaned and sanitized, making them an ideal choice for food processing, packaging, and storage.

Send your message to us

Painted Aluminum Sheets 5x10 - Aluminium Alloy and Sheet for Building Industrial

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords