Rigid Aluminum Foil Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

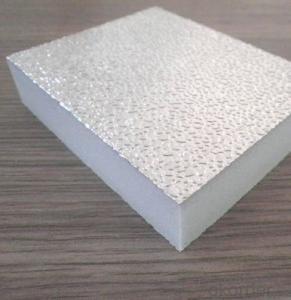

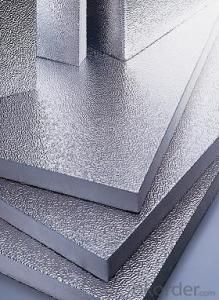

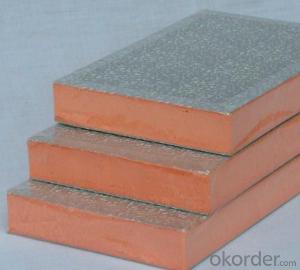

Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel

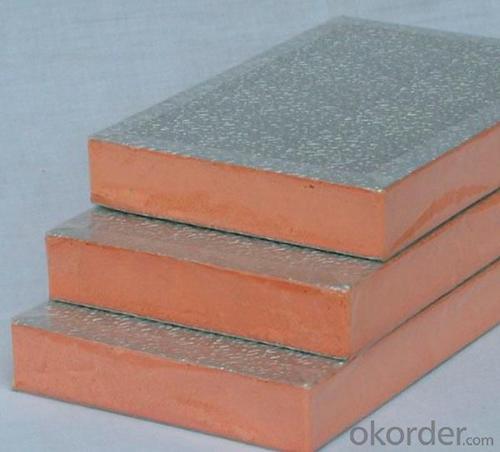

1.Structure of Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel

Air ductwork supply is pre-insulated aluminum panels constructed of both aluminum and Poly-isocyanurate. The sandwich panels are comprised of expanded Poly-isocyanurate rigid foam board, faced on both sides by aluminum foil.Ducting is the key part of any central air-conditioning system. It is similar in function to the arteries and veins in the human body as it helps in regulating the temperature in a building. The material used for making ducts for air-conditioning is constantly evolving in order to satisfy the demand for higher thermal efficiency, eco-friendliness, and increased energy savings. Many different materials and systems such as magnetite composite, PVC and so on have been developed as alternatives to the galvanized sheet metal used traditionally. But pre-insulated ducting materials is by far the most popular ducting system in use today. It is essentially a panel made with an insulating material such as PIR (Polyisocyanurate), PUR (Polyurethane) or Phenolic foam material sandwiched in between two layers of aluminium foil. Such a foam panel is easier than traditional galvanized sheet metal to manipulate for complex designs and lighter than its predecessors for installation. These qualities in addition to the fact that it has a much higher thermal efficiency than galvanized sheet metal make it an ideal material for fabricating Airconditioning ducts in harsh climates like the Gulf. Its application has been gradually extended to every type of air distribution system: industrial and commercial.

For construction of air ducting in HVAC systems, the Polyisocyanurate (PIR), PUR (Polyurethane) and/or Phenolic foam panel with 45kg/m3 density, coated with 80/80µm thick embossed aluminum foil have two panel types:

The air ducts fabricated using ALU 80/80 panels can be installed in plants:

with air speed up to 15m/s

with pressure up to 1000Pa

indoor

The air ducts fabricated by using ALU 80/200 panels can be installed in plants:

with air speed up to 35m/s

with pressure 1750Pa

outdoor

2.Main Features of Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel:

Air Duct Panel / Pre-insulated Duct Panel / HVAC Duct Panel :

HVAC Aluminum Foil Duct Board

1. Be used for HVAC Duct system;

2. BS 476 Part 6&7 Class 0.

3. Low thermal conductivity.

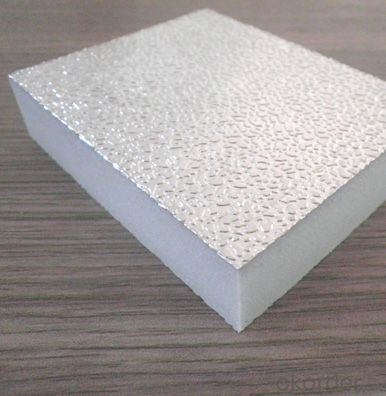

3.Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel Images

Our embossed aluminum sheet/Coil series include:

1.diamond embossed aluminum sheet/Coil

2.orange peel embossed aluminum sheet/Coil

3.stucco embossed aluminum sheet/Coil

4.Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel Specification

Air-conditioning Areas Exposed to weather

Thickness of panels 20 Mm 30 Mm

Thickness of aluminum 80/80 Microns 80/200 Microns

Density of the foam 44-48 Kg/m3 42-48 Kg/m3

Finishing of aluminum Embossed Embossed

Dimension Length: 4meter Width: 1.2meter

Note: Both sides of the aluminum foil are lacquered with a 3g/m2 weatherproof and ultraviolet ray protection polyester lacquer.

Certificate: FORM A, CO ,FORM E ,FORM B ,MTC, SGS and ROHS(client paid for it), MTC

Surface Quality: without any dent, scratches, oiliness , oxidation .

Chemicial composite and Machinary Property: Meet with GB/T, JIS,ENAW, ASTM standard

Month Capacity: 5000MT/month

exporting port: Tianjin, Shanghai

payment: TT or LC at sight

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long for your delivery time?

Commonly 30 working days can be served. If you need the products urgently, we can shorten the delivery time into 20 days.

3. Where the Panels can't be used?

As extractors in the kitchen, as chimneys for smoke or chemical laden smoke

As transportation for solids

Outside temperature range -35ºC and +110ºC

Air speed >15m/s for 20mm thick panel and >35m/s for 30mm thick panel

when the negative or positive pressure inside the duct is: 20mm thick panel >1000Pa and 30mm thick panel >1750Pa

- Q: ya I already have a color t.v and on of those crappy t.v antennas how can I amplfy the antenna to get more channels? should I try alummuim foil?

- Wow, you got all kinds of answers.none of them very goodYou need to spend some time looking at The Radio Ameteur's HandbookIn there are pages and pages of antenna theory and construction articles for various antennasMaterials you will need: Plexiglass for insulators aluminum tubing for elements Aluminum tubing or a long wood pole for a boom to mount the elements upon300 ohm ribbon cable for feedline, or 75 ohm coax feedline depending upon the type of driven element you choosea folded dipole requires 300 ohm feed a half wave dipole requires 75 ohm feed I would suggest you look into the idea of a 3 element beam antenna.not to hard to build at homeyou need to determine what channels the antenna is going to work on - that determines the length of the elementsThe driven element is the one that is most criticalEach Television Channel has a Frequency (Sound and Picture)Look this up on the Internet using a searchThen use L 468/Freq in Mhz to get the element length for a half wave dipoleThe director should be 8 percent shorterThe reflector should be 8 percent longerUse some of the spacing information in the handbook to get a rough idea of element spacing in inches.

- Q: I think it would be a good time to market such an item.Lead content clothing or is there some other sort of material?

- Depends on the kind of scanner - millimeter wave or x-rayFor the x-ray scanner, if you wore a thin layer of lead foil inside your clothes, then it might show up as an uninterpretable area on the scan - either all black or all white - not sure whichA very fine mesh metal screening might affect the millimeter wave scanner, but I don't know for sureYou would have to put that foil inside your shirt, since I don't think you can wear a coat into the scanner chamberThe foil would need to be thin in order to be flexible, and, since it is thin, would develop cracks after a while, as aluminum foil does, only fasterHowever - I am quite certain that the TSA people would take you aside for an extra thorough pat down, and likely a trip to a separate room for you to remove your shirtThey would not let you past the check point without knowing why that blank area occurredI am sure that they would not be amusedThe only thing this will accomplish is to delay your screening, and inconvenience you, and perhaps others who are stuck in line behind youWhy would you want to mess up everyone's trip?

- Q: Should a single layer of paper or plastic film insulate the aluminum foil from the screen?

- 2. when the cable is double insulated and shielded, the outermost shield is grounded at both ends, and the inner layer is shielded at one end with equipotential grounding.

- Q: firstly, what are the metal/alloy used in:cambell's soup cansmilo canspaint bucketsare they all tin?secondly:i have heard that we are not allowed to put metals in the microwave but i have done it with aluminium foil and it glows a little (like a bulb filament), however, that's only due to the electromagnetic currents and it doesn't spoil the microwaveshould be fine right? (assuming that the container is an open body and expanding gases are not an issue) i have heard about the metal reflecting the waves but it doesn't make senseelectromagnetic shielding occurs only with magnetic material (iron steel etc) so other nonmagnetic metals should be safe.please answer even if you only know answers to 1 questions :)

- Carbon nano tubes are stronger then steel, lighter then aluminum and more flexible then plasticWe're only a few years of from being able to mass produce it.

- Q: does rhubarb keep longer in the refrigerator?

- It will depend on what you are making a Pyrex casserole dish will do, but they are not stove top friendlyA roasting dish and tinfoil would be a last resort.

- Q: I want to make a really nice lasagna but I'm really bad at making it.Can anyone give me some easy steps on how to make a cheese lasagna.And how long it takes to cook.I try to follow recipes, but it still doesn't come out right.Thankyou :)

- use McCormick's BBQ seasoning smoke 2.5-3.5 hr maintaining a temp of 225-250 deg I prefer cattleman's sauce, you don't have to depend on your taste.

- Q: the muhibah company is a manufacturer of cylindrical aluminium tinsthe manager plans to reduce the cost of productionthe production cost i proportional to the area of the aluminium sheet usedthe volume that each tin can hold is 1000cm^3 (1 liter).1) determine the value of h, r and hence calculate the ratio of h/r when the total surface area of each tin is minimumhere, h cm denotes the height and r cm the radius of the tin.2) the top and bottom pieces of the tin of height h cm are cut from square-shaped aluminium sheetsDetermine the value for r, h and hence calculate the ratio h/r so that the total area of the aluminium sheets used for making the tin is minimum.3) investigate cases where the top and bottom surfaces are cut fromi) equilateral triangleii) regular hexagonfind the ratio of h/r for each casesplease help me to solve this problem,,, thanks for ur help

- Hints on the first two: 1Minimize A 2 pi r^2 + 2 pi r h subject to pi r ^ 2 h 10002Minimize A 8 r^2 + 2 pi r h subject to pi r ^ 2 h 1000.

- Q: 1) Boron, Sodium, Oxygen, Sulfur, Potassium2) Boron, Phosphorus, Aluminum, Silicon, Chlorine

- This Site Might Help YouRE: What's the difference between nylon and lycra? Is there such a fabric made 100% of lycra? If so, where to find it?

Send your message to us

Rigid Aluminum Foil Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords