Alloy Steel Pipe Fittings Butt-Welding End Caps

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding End Caps

Features standards and products of our Butt-Welding End Caps:

Features of Butt-Welding End Caps:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding End Caps:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding End Caps:

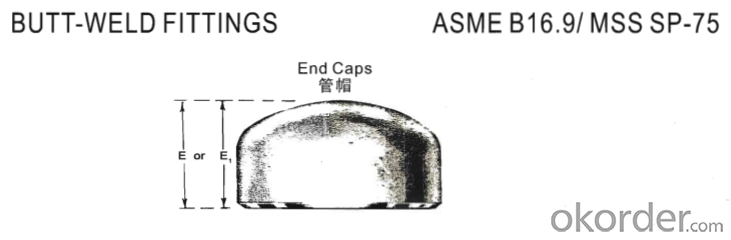

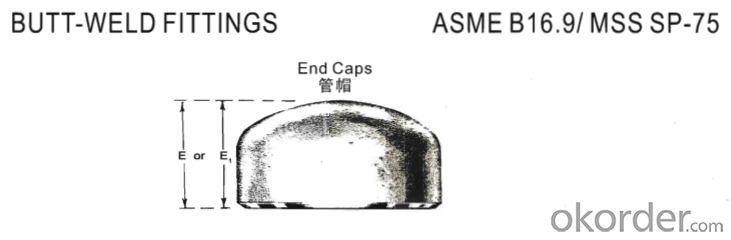

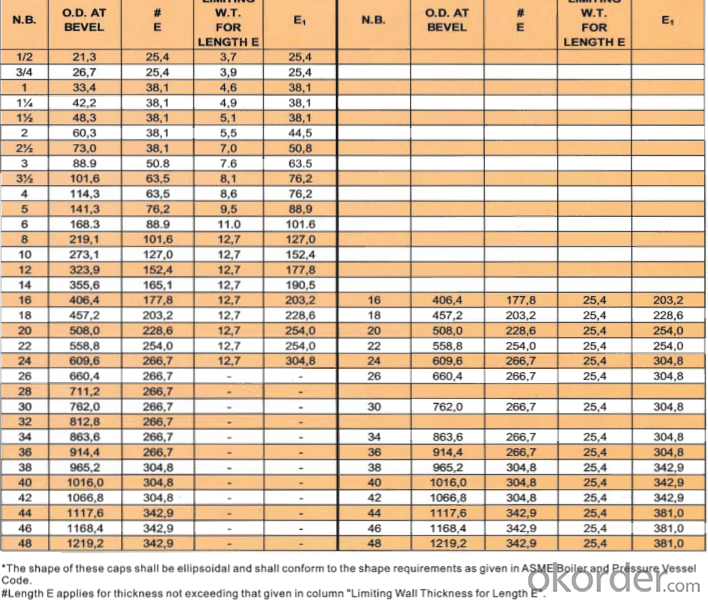

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding End Caps:

Packing of Butt-Welding End Caps:

FAQ of Butt-Welding End Caps:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: ya know the really cute hairstyle with the little bump on the top of the head. yeah, il love that but i SUCK at it. like EVERYtime i try to do it, i screw up and it comes out ugly and even. i just need somebody to direct me to a web site or to give me diredctions themselves on how to do it. please help me!

- this is just the tip of the iceburg. there has been so much wasted in Iraq its ridiculous

- Q: In the Sweet Brown Aint Nobody Got Time For That remix by theparodyfactory1, there is a video clip of 3 guys dancing at 0:59 seconds. It looks like it might be from the 80's or 90's. Does anyone know what it is?

- stud there is supposed to be a new online section for tire reviews, I don't know if stud less snow tires were tested, but lets hope so for your sake, and americas tire may not have a tire store near you, but their website has a section for customer reviews after you pick a certain make of tire, if the snow tires are still on the website, you may find more information. ADDITIONAL DETAILS, I took a look on the new tire rack web site and there is a section for tire testing for snow tires, the Bridgestone/Firestone Blizzak tested as well as any other of the stud less snow tires and there is now a section for customer long term reviews for many different tires that may be helpfull as well.

- Q: In a closed circuit alarm (correct me if I'm wrong) a magnet pulls a metal switch closed so electricity can flow to the alarm, arming it, when the door opens and the magnet releases the switch the electricity is cut off and the alarm starts making some noise.Is the magnet inside the door?

- Go to your local hardware store and tell them what your doing. They will help you use the right fitting. When I do a job like that I also use silicon in the joint, BUT, you must fit everything together 100% correctly and you also must tighten everything then let it sit four 6 to 8 hours for the silicon to set up before you turn on the water. I have never had a leak.

- Q: what ways can you masturbate?

- ascertain that the examining is genuine, I relatively have wide-unfold meter readers to head incorrect, I additionally understand of a case the place the electrical powered guy study the gas meter ( the bill became for ?800). in the event that they look into then ask the two your landlord or the gas furnish organization to coach you the previous expenses, the two to make certain if there became an expected bill, and additionally to make certain what quantities are existence like for the summer season useage. I agree you are able to desire to be paying somebody elses bill, gas companies prefer to get their money from whoever is stupid sufficient to pay them whilst they can't gets a commission from previous tennants. Take copies of the expenses to voters suggestion or ask them to help you acquire them in case you have difficulty. don't be suprised if the gas organization would not assist you, in case you're particular the useage isn't yours, enable them to take you to court, after first sending them a letter informing them which you will anticipate reimbursement for attendance i.e. misplaced wages, return and forth, rigidity, deformation of character and so on. earnings all of the information you are able to as Judges/Magistrates are to 3 volume human.

- Q: thereis a 1 foot long piece that comes out from a fitting in the masonry - I don't feel good abouit lighting a wood fire in teh fireplace with the black pipe in there. the end of the blackp pipe is open. Very rusty, can't get the elbow fittings loose. Thinking about cutting off the pipe, but howw to seal it against fireplace heat? Really want to use the fireplace for wood.

- cellotape. wrap it round your fingers then use the sticky side to pick up the stuff.

- Q: My computer running XP as made my control panel just dissapear. I tried going to run and typing control.exe and it says This operation has been cancelled due to restrictions in effect on this computer. Please contact your system administrator. I am the adminitrator!!!! I have Windows one care and it also keeps popping up with trojans that I tell it to clear all. Then it says successfully removed then pops right back up with the same trojan detected??? What gives?? I contacted Microsoft and waiting for a response. Any help would be awesome thank you.

- Most likely nothing. Lightning, being electricity, takes the path of least resistance to ground. It also usually strikes the highest object in the area. Since a shingle and wood roof are very poor conductors of electricity, the current is most likely to hit a conductor or search for the best conductor to ground.

- Q: I've recently heard that people felt that Tiger Woods got it easier than the average Joe because he was able to pick a time that the police would talk to him. I know you pay taxes too but, he's rich and more of his tax dollars go into police protection, the fire department, and military protection than us individually. So since he pays more, should he have better relationship with the police than the middle class?

- the standard method is to not mix/match pvc materials. the different fittings will fit fine.however, abs pipe should use abs fittings and pvc pipe with pvc fittings. if youi absolutely need to glue pvc fittings to abs then you should use purple primer with either a solvent cement for pvs or abs..

- Q: I was driving last night, and wasn't paying attention to where I was going in a parking lot and hit and knocked over a fire hydrant I didn't really notice what I did (I thought I just hit the curb) there was no water running to it yet I guess. so I drove away the next day I noticed my bumper was bent and had some paint on it. I know somebody had to'v got my plate can I get in serious trouble for this, if so what?

- I experience wearing head to toe protection. No leather-based or one piece, yet padded and armored fabric jackets and pants. complete face helmet is the only helmet to positioned on. I went down some years in the past after hitting a dogs. Jacket took the brunt of the impact. Sore shoulder that felt wonderful here day. Knee became the different area that hit the pavement. denims furnish approximately 0 protection from street rash. Knee became skinned and took 5 WEEKS to heal. feet of running shoes all abraded, yet no longer in any respect felt a ingredient. Boots are equipped with a hard plastic toe cap under the leather-based. I even have 5 jackets, 3 pair of pants, 3 pair of gloves, rain jacket and pants, 2 helmets, 2 pair of running shoes, and an Icon protection vest.

- Q: I need help on finding out what's a good alarm system for my 1997 honda accord sedan. I don't want remote start just looking for an alarm that has siren an locks and unlocks. One that is not to expensive I want something more affordable but also works great and can keep my car safe. I don't know to much about alarms so please help.

- Sounds like you have a build up of scale in your pipes. If the black specks are hard then it is most likely scale and that will be coming from the pipes. If they are rubber like then you may have a rubber seal somewhere in the system that is falling apart slowly. Anyway you say that it is only a big rush of water to this particular outlet so it is something to do with this line. If it only happens in the one spot in your house, the main bathroom then that isolates it to the pipes or fittings on that leg of your plumbing. You say you have replaced the faucet so you know how to turn your mains supply water to your house on and off. I suggest you try to isolate the problem even further. Turn your water off; open a faucet to relieve the pressure in your hot water sytem tank. Remove the outlet pipe from your hot water service and have someone turn the mains tap on again but catch the water in a bucket. Check if the black specks are there or not, if they are then the problemn is further up stream, if not then it is further downstream which I think it probably is but you need to eliminate the origin of the specks. I think you probably get where I am going with this, keep tracking until you find what area the specks are coming from. If you find it is in the pipes you can flush them with all sorts of things to clean them out. But you will be forced to repeat fairly regularly as scale is just rust which breaks away and flows with the water. If you have copper pipes there may be a piece of steel pipe in the line and that is where your scale will be coming from. If the specks are coming from the heater and depending on what they are as to how you will need to deal with it. If all else fails take a sample of the specks to your local hardware or plumbing store, look for the oldest person working there and explain what is going on and what you know about the source. They may be able to help. Best of luck

- Q: I have this sniper it costed me 300 bucks ive had it for about a year and its fps is between 350-450 somewhere and i wanna know on a scale of 1-10 how good it is. We play hardcore airsoft and play in the wilderness with ghillie suits and we are playing pro so we can be firing up to 1000 feet away and tbh when i fire the sniper bullets go really fast starting out and they immedtialey drop in the middle of the air like a dive bomb anyways is 350-450 for a airsoft sniper good for hardocre long range playing in the wilderness?

- Try using a oil free face primer before you put foundation on it creates a shield between your skin and the makeup, therefore combating shine longer. Also set the foundation with a shine free loose powder and you will be good to go for the whole day! hope i helped ;]

Send your message to us

Alloy Steel Pipe Fittings Butt-Welding End Caps

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords