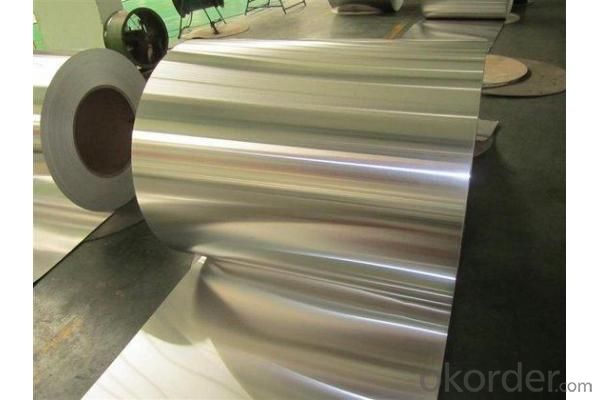

Coil Aluminum Stock - Alloy Aluminum Coil 5005 5754 H32 H24 O for Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Alloy | Temper |

1050 1060 1070 1100 | H112, H24, O |

2024 LY12 LY11 2A11 2A14 2017 2A17 | H112, T4, T351, T6 |

3A21 3003 3103 3004 3005 3105 | H112, H24, O |

5052 5754 5005 5083 5086 | H32, H112, H111, H24, O |

6063 6061 | H112, T6, T651, T5, T4,O |

Specification | 1.Thickness: 0.2-60mm 2.Width: 500-2000mm 3.Length:According to requirement 4.Temper: Various status Coils can be produced as your request. |

Application | Mainly used in construction, decoration, packaging, printing, covers material, signs,billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration |

Alloy Series | Typical Alloy |

1000 Series | 1050 1060 1070 1100 |

2000 Series | 2024(2A12), LY12, LY11, 2A11, 2A14(LD10), 2017, 2A17 |

3000 Series | 3A21, 3003, 3103, 3004, 3005, 3105 |

4000 Series | 4A03, 4A11, 4A13, 4A17, 4004, 4032, 4043, 4043A, 4047, 4047A |

5000 Series | 5052, 5083, 5754, 5005, 5086,5182 |

6000 Series | 6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02 |

7000 Series | 7075, 7A04, 7A09, 7A52, 7A05 |

Chemical Composition:

Packaging & Shipping

| Packaging Detail |

Coil is placed to the iron or wooden pallet ,rapped by water-proof kraft paper perfectly , then strong fixed by GI iron narrow belt .( About 2.5 ton / pallet ) |

| Dimension | 20 CM x 1220MM X 2440MM |

| Container | 20FT Container can load 25 tons max ; 40FT Container can load 27 tons max ; |

| Shipping | By Sea 20ft/40ft Container |

Our services

Main Services:

> Precision aluminum plate

> Casting products

> Forging products

Special Services:

> Alloy selection

> Aluminum machining techniques

> Hot working

> Surface treatment

Our Promise

---High quality stainless steel with reasonable price.

---Wide excellent experiences with after-sale service.

---Every process will be checked by responsible QC.

---Professional packing teams which keep every packing safely.

---Trial order can be done in one week.

---Samples can be provided as your requirements.

FAQ

Q: Do you have the CE, TUV, UL Certification?

A: We’ve already passed all the tests, and any certificate is available.

Q: Have you ever sold your products to companies in my country?

A: Of course, we have customers in all general PV markets, but I think we should expand our market share along with the market growth.

Q: How do you pack your products?

A: We have rich experience on how to pack to make sure the safety on shipment when it arrives at the destination.

Q: Can you do OEM for us?

A: Yes, we can.

Q: Can we visit your factory?

A: Surely, I will arrange the trip basing on your business schedule.

- Q: What are the potential applications of coil-embossed aluminum coils?

- Coil-embossed aluminum coils have a wide range of potential applications due to their unique features and properties. Here are some of the potential applications: 1. Building and construction: Coil-embossed aluminum coils can be used in the construction industry for various purposes. They can be used as roofing materials, wall cladding, and exterior decorative panels. The embossed pattern provides aesthetic appeal and enhances the overall appearance of the building. Additionally, the corrosion-resistant properties of aluminum make it a durable choice for outdoor applications. 2. Automotive industry: Coil-embossed aluminum coils find applications in the automotive industry. They can be used for manufacturing body panels, trims, and decorative elements for vehicles. The embossed surface adds texture and style to the automotive components while providing durability and resistance to wear and tear. 3. Appliances and electronics: The embossed patterns on aluminum coils make them suitable for use in appliances and electronics. They can be used for manufacturing refrigerator panels, microwave casings, and other household appliances. The textured surface can also enhance the grip on handheld electronic devices. 4. Packaging industry: Coil-embossed aluminum coils have potential applications in the packaging industry. They can be used for manufacturing packaging materials such as cans, containers, and lids. The embossed surface can provide a unique branding opportunity, allowing companies to create visually appealing packaging designs. 5. Signage and advertising: The embossed patterns on aluminum coils can be utilized in the signage and advertising industry. They can be used for manufacturing outdoor signs, billboards, and display panels. The embossed surface adds depth and dimension to the signage, making it more eye-catching and attractive. 6. Furniture and interior design: Coil-embossed aluminum coils can be used in the furniture and interior design industry. They can be used for manufacturing decorative panels, furniture trims, and accents. The embossed patterns can add a touch of elegance and uniqueness to furniture and interior spaces. 7. Renewable energy: Aluminum is a lightweight and corrosion-resistant material, making it suitable for renewable energy applications. Coil-embossed aluminum coils can be used for manufacturing solar panels and wind turbine components. The embossed surface can enhance the efficiency of solar panels by increasing light absorption and reducing reflection. Overall, coil-embossed aluminum coils have a wide range of potential applications across various industries. The embossed patterns, along with the inherent properties of aluminum, make them a versatile material choice for both functional and aesthetic purposes.

- Q: What are the bending and forming capabilities of aluminum coils?

- Due to its inherent properties as a malleable and ductile material, aluminum coils possess outstanding abilities in bending and forming. The high strength-to-weight ratio of aluminum allows for easy shaping and forming without compromising its structural integrity. In terms of bending, aluminum coils exhibit remarkable flexibility and can be bent into various shapes and angles without any risk of fracturing or cracking. This flexibility enables the formation of tight curves or gentle bends, making aluminum coils suitable for a wide range of applications. Particularly in industries such as construction, automotive, and aerospace, where curved or intricate shapes are often needed, the flexibility of aluminum coils proves to be highly advantageous. In the realm of forming, aluminum coils can be effortlessly manipulated into different forms, including flat sheets, tubes, or intricate profiles. This versatility makes aluminum coils highly sought after in industries that prioritize customization and design flexibility. Moreover, aluminum coils can undergo various forming processes, such as roll forming, stamping, and deep drawing, which allow for the transformation into different products with precise dimensions and tolerances. These exceptional forming capabilities make aluminum coils the preferred choice for manufacturing components like automotive body panels, roofing materials, heat exchangers, and structural elements. In conclusion, the exceptional bending and forming capabilities of aluminum coils make them an ideal choice for applications that demand flexibility, durability, and design versatility.

- Q: How are aluminum coils processed for specific thicknesses?

- To achieve specific thicknesses, aluminum coils undergo a series of manufacturing steps. The journey begins by casting molten aluminum into large ingots. These ingots are then transformed into thin sheets through the use of a hot rolling mill. To reach the desired thickness, the first step is hot rolling. The aluminum sheet is gradually reduced in thickness as it passes through a sequence of heated rollers. This process is repeated several times, with reheating occurring between each pass. Through hot rolling, the sheet is elongated and made thinner. Following hot rolling, the sheet may undergo cold rolling. This involves passing the previously hot rolled sheet through a set of cold rollers. Cold rolling further decreases the thickness and enhances the surface finish of the aluminum. It also enhances the material's strength and hardness. After this, the sheet is annealed. This entails heating it to a specific temperature and then allowing it to cool gradually. Annealing serves to relieve any internal stresses and enhance the overall ductility of the aluminum. Once the desired thickness is achieved, the aluminum sheet is typically cut into coils using a slitting machine. These coils can then undergo further processing or be utilized in various applications, such as the manufacturing of automotive parts, packaging materials, or building construction. In summary, the process of producing aluminum coils with specific thicknesses involves hot rolling, cold rolling, annealing, and slitting. These steps ensure that the aluminum sheet meets the required thickness specifications and is ready for further use in diverse industries.

- Q: What is the acceptable range of temperatures for aluminum coils in terms of their functionality and durability?

- <p>The temperature range for aluminum coils can vary depending on the specific application and alloy type. Generally, aluminum coils can operate effectively within a range of -200掳F to 500掳F (-129掳C to 260掳C). For most industrial applications, the working temperature is between -40掳F to 300掳F (-40掳C to 150掳C). However, it's important to consult the manufacturer's specifications for the exact temperature limits of a particular aluminum coil, as these can differ based on the alloy and intended use.</p>

- Q: Is it possible to use a grinder for cutting aluminum coil?

- <p>Yes, you can use a grinder to cut aluminum coil, but it's essential to choose the right type of grinder and blade. A metal cutting grinder with a suitable blade designed for cutting aluminum is recommended. Ensure the blade is sharp and the grinder is powerful enough to handle the material. Always wear appropriate safety gear, including gloves and eye protection, as cutting aluminum can produce sharp edges and flying debris. Be cautious of the heat generated during cutting, as it can warp or damage the aluminum.</p>

- Q: How is an aluminum coil made?

- An aluminum coil is made through a process called continuous casting and rolling. First, pure molten aluminum is poured into a continuous casting machine, which creates a solidified strip of aluminum. This strip is then fed through a series of rolling mills, where it undergoes multiple passes to achieve the desired thickness and shape. The rolling process also helps in improving the mechanical properties of the aluminum coil. Finally, the coil is coiled up and is ready to be used for various applications such as in construction, automotive, or packaging industries.

- Q: Aluminum is directly below Mg. If aluminum is oxidized so readily, then how can we make planes or ships out of it and they don't fall apart after a few months or years?

- Yes aluminum does oxidize just like any other metal. The difference is that aluminum oxidizes the same color as the metal therefore you cannot tell that is oxidizing. Once is oxidizes a little bit, the oxidize protects the metal and it does not oxidize any more.

- Q: Can aluminum coils be used for electrical wiring?

- Yes, aluminum coils can be used for electrical wiring. Aluminum is a commonly used material for wiring due to its high conductivity and affordability. However, it requires special precautions and techniques during installation to ensure proper connections and prevent potential risks such as corrosion or overheating.

- Q: Describe the process of rolling aluminum coil in a few sentences.

- <p>The process of rolling aluminum coil involves several key steps. Initially, aluminum ingots are heated to a specific temperature to make them pliable. Then, they are passed through a series of rolling mills where the ingots are pressed and shaped into thin sheets or coils. This process reduces the thickness and increases the length and width of the material. During rolling, the aluminum may be annealed to improve its ductility and strength. After rolling, the aluminum coil is cooled, cleaned, and inspected for quality. The final step includes coiling the rolled aluminum into manageable rolls for storage and transportation. This process is critical for producing aluminum coils used in various industries such as construction, automotive, and packaging.</p>

- Q: My boyfriend sweats a lot and uses Mitchlum deodorant, a lot of it, under his armpits and waits til it dries to stop the sweating. I heard aluminium was bad for you, but he says natural deodorants don't work as well. What do you think?

- different styles and types of deodarants work on different people experiment on lots of deodarant and see which one where u can not use to much but is still petty effective

Send your message to us

Coil Aluminum Stock - Alloy Aluminum Coil 5005 5754 H32 H24 O for Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords