5052 H32 Aluminum Alloy Coil - Continuous Cast Aluminum Coil 5005 5052 5083 for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Continuous Cast Aluminium Coil 5005 5052 5083 for Building

Name | Aluminum Coil |

Brand | CNBM |

Alloy | 1100H-18, 3003-H24,3003-H26,3005-H26,8011,3004,3105,5005,etc. |

Thickness | 0.1~1.5mm |

Width | <2000mm< span=""> |

MOQ | 1 MT |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 1MT - 2MT |

2. Application of Continuous Cast Aluminium Coil 5005 5052 5083 for Building

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Continuous Cast Aluminium Coil 5005 5052 5083 for Building

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

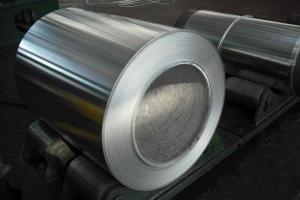

5. Image of Continuous Cast Aluminium Coil 5005 5052 5083 for Building

6. Package and shipping of Continuous Cast Aluminium Coil 5005 5052 5083 for Building

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in food processing industries?

- Aluminum coils find applications in the food processing industry. This is because aluminum possesses several advantageous properties that make it a popular choice in this field. It is a lightweight and flexible material with excellent thermal conductivity. These characteristics make it ideal for various uses such as refrigeration, heat exchangers, and ovens in food processing. Moreover, aluminum is non-toxic, resistant to corrosion, and does not affect the taste or odor of the food being processed. Therefore, it is a safe and hygienic option for food processing equipment. Additionally, aluminum coils are easy to clean and maintain, ensuring the highest standards of cleanliness and food safety are upheld. Consequently, due to their outstanding performance and suitability for food-related applications, aluminum coils are widely accepted and utilized in the food processing industry.

- Q: What are the energy efficiency benefits of aluminum coils?

- Aluminum coils provide numerous energy efficiency benefits that make them a preferred choice in various industries. Firstly, aluminum is an excellent conductor of heat, allowing for efficient transfer of thermal energy. This property is especially advantageous in the HVAC industry, where aluminum coils are commonly used in air conditioning and refrigeration systems. The high thermal conductivity of aluminum ensures that heat is effectively absorbed or released, resulting in faster cooling or heating processes and lower energy consumption. Additionally, aluminum coils possess exceptional corrosion resistance, which helps maintain their efficiency over time. Unlike other metals that may deteriorate due to exposure to moisture or chemicals, aluminum remains unaffected, ensuring optimal heat transfer efficiency throughout the lifespan of the coil. By preserving the coil's performance, energy losses due to reduced heat transfer are minimized, resulting in energy savings and increased system efficiency. Another significant advantage of aluminum coils is their lightweight nature. Compared to traditional copper coils, aluminum coils are significantly lighter, making them easier to handle during installation and maintenance. The reduced weight also translates into lower energy requirements for transportation, resulting in reduced carbon emissions associated with shipping. Furthermore, aluminum is a recyclable material, making it environmentally friendly and sustainable. The recycling process of aluminum requires significantly less energy compared to primary production, leading to reduced greenhouse gas emissions. By choosing aluminum coils, businesses can contribute to a more sustainable future by reducing their carbon footprint. Overall, the energy efficiency benefits of aluminum coils are vast. Their excellent thermal conductivity, corrosion resistance, lightweight nature, and recyclability make them an ideal choice for various applications, leading to reduced energy consumption, enhanced system performance, and a more sustainable environment.

- Q: Are there any environmental considerations when using aluminum coils?

- Yes, there are several environmental considerations when using aluminum coils. Firstly, the production of aluminum coils requires mining and extraction of bauxite, which can lead to habitat destruction and biodiversity loss. Additionally, the extraction and refining processes consume significant amounts of energy, contributing to greenhouse gas emissions. However, aluminum is highly recyclable, and using recycled aluminum reduces the environmental impact by saving energy and reducing waste. Proper disposal and recycling of aluminum coils are crucial to minimize environmental harm.

- Q: I can't figure out what the metabolic role of aluminum is. Been searching for a while and can't seem to find anything concrete.If you can, please include sources. Thanks!

- I don't think it has any role.

- Q: This question asks for the distinctions between two forms of aluminum used in various industries: coils and sheets.

- <p>Aluminum coil and aluminum sheet are both flat aluminum products but differ in form and usage. Aluminum coil is a long, continuous roll of aluminum that can be easily cut to length and is often used for manufacturing processes like stamping, bending, and forming. It's ideal for applications requiring a consistent and uniform supply of material. On the other hand, aluminum sheet is a flat, rectangular piece of aluminum with a specific thickness, width, and length. It is used for applications where a single piece of material is needed, such as in construction, signage, and decorative purposes. The main difference lies in the form factor and the way they are used in manufacturing and construction processes.</p>

- Q: Are aluminum coils easy to install?

- Yes, aluminum coils are generally easy to install. They are lightweight and flexible, making them convenient to handle and position during installation. Additionally, they can be easily cut and shaped to fit the desired space, making the installation process relatively straightforward for experienced professionals or DIY enthusiasts.

- Q: How do aluminum coils compare to other metal coils like steel or copper?

- When comparing aluminum coils to steel or copper coils, there are several advantages and disadvantages to consider. In terms of weight, aluminum coils are significantly lighter than steel coils. This makes them easier to handle and transport, resulting in potential cost savings for the manufacturing and construction industries. On the other hand, steel coils offer superior strength and durability, making them more suitable for heavy-duty applications where strength is crucial. When it comes to corrosion resistance, aluminum coils have a natural oxide layer that protects them from rust and corrosion. This makes them an excellent choice for outdoor applications or environments with high humidity. While copper coils also have excellent corrosion resistance, steel coils are more susceptible to rust and require additional protective coatings. Thermal conductivity is another important factor to consider. Copper is well-known for its exceptional thermal conductivity, making it highly efficient for applications that require heat transfer, such as HVAC systems. Although aluminum coils have lower thermal conductivity than copper, they are still widely used in various heat transfer applications due to their lightweight nature and cost-effectiveness. Cost is a significant consideration when comparing different metal coils. Generally, aluminum coils are more affordable than copper and steel coils, making them a popular choice in many industries. However, for heavy-duty applications, steel coils often provide the most cost-effective option due to their superior strength and durability. Ultimately, the choice between aluminum, steel, or copper coils depends on the specific requirements of the application. Each metal possesses its own unique properties and advantages, and selecting the appropriate material involves considering factors such as weight, strength, corrosion resistance, thermal conductivity, and cost.

- Q: What is the temperature range within which aluminum coil can be used?

- <p>Aluminum coil can be used within a wide temperature range, typically from -200掳C to 150掳C. At low temperatures, it retains good ductility and strength, while at higher temperatures, it maintains its form and conductivity. However, it's important to note that prolonged exposure to temperatures above 150掳C can lead to a loss of mechanical properties over time. Always refer to specific product data sheets for precise temperature limits.</p>

- Q: What are cold rolling aluminum coil and hot rolling aluminum coil? What are their features?

- If the rolling temperature is above the crystallization one, it is hot rolling, otherwise it is cold rolling.

- Q: What are the potential fire hazards associated with aluminum coils?

- Aluminum coils present various fire hazards that need to be addressed. The primary concern is the high flammability of aluminum, making it susceptible to catching fire easily and burning rapidly. This poses a significant danger if there is a nearby ignition source, such as an open flame, electrical spark, or hot surface. Another fire risk arises from the accumulation of dust, dirt, or other combustible substances on the aluminum coils. These materials can serve as fuel for a fire, raising the probability and intensity of combustion. To prevent the buildup of such substances, it is essential to regularly clean and maintain the coils. Improper installation or maintenance of aluminum coils in HVAC systems can also result in fire hazards. Inadequate fastening or loose electrical connections can lead to overheating and potentially spark a fire. Moreover, if aluminum coils come into contact with live electrical wires or experience a short circuit, electrical fires can occur. This may happen if the coils are installed too close to electrical components or if there are issues with the insulation or grounding of the system. Furthermore, the use of flammable refrigerants in HVAC systems heightens the fire risk associated with aluminum coils. Leaks or malfunctions in the refrigerant system can create a flammable environment around the coils, potentially causing a fire or explosion. To mitigate these fire hazards, it is crucial to adhere to proper installation guidelines, regularly inspect and maintain the coils, keep the surrounding area free from combustible materials, and ensure there are no electrical or refrigerant leaks in the system. Additionally, it is advisable to have fire detection and suppression systems in place to promptly respond to any potential fire emergencies.

Send your message to us

5052 H32 Aluminum Alloy Coil - Continuous Cast Aluminum Coil 5005 5052 5083 for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords