AISI 4340 Forged Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 4340 Forged Steel Round Bars

Technical Paramenters

Chemical Composition | Mechanical Properties (In Quenched & Tempered State) | ||

C | 0.38-0.43 % | Tensile strength(MPA) | ≥980(100) |

Si | 0.15-0.35 % | Yield strength (MPA) | ≥835(85) |

Mn | 0.60-0.80 % | Elongation (δ5/%) | ≥12 |

Cr | 0.70-0.90 % | Reduction in Area (ψ/%) | ≥55 |

Ni | 1.65-2.00 % | Impact (J) | ≥ 78 |

P | ≤0.035 % | Impact toughness value αkv (J/cm2) | ≥98(10) |

S | ≤0.040 % | Hardness | ≤269HB |

Mo | 0.20-0.30 % | ||

Standard | ASTM A29/A 29M-05 | ||||||||||

Grade | 4340 | ||||||||||

MOQ | 1 Metric Ton | ||||||||||

Diameter | 8mm~1500mm | ||||||||||

Length | 6m,12m or as required. | ||||||||||

Diameter Tolerance | As required | ||||||||||

Condition of delivery | Hot rolled,Cold Rolled or as required. | ||||||||||

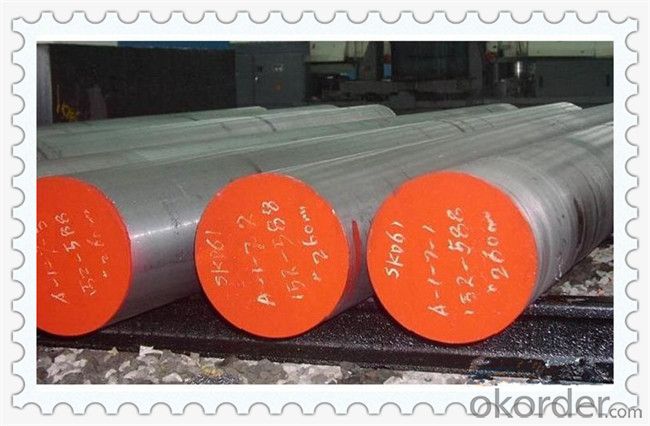

Products Show

Product Overviews

Steel wire, Steel Round bar

Diameter: 0.14mm-2000mm

Steel Square bar

Size : 50mm * 50mm-600mm *600mm

Steel Plate(sheet), flat steel bar

Thickness: 0.1mm-800mm Width: 10mm to 1900mm

Cold-rolled Plate(sheet)

Thickness: 0.1-8mm Width: 1000mm

Hot-rolled Plate(sheet)

Thickness: 6-200mm Width : 210-1900mm

Surface: 2B, BA, 6K, 8K, 12K, etc.

Welded/seamless Steel Pipe(tube)

outer diameter: 6-219mm wall thickness: 1-35 mm.

Length:according to the customer's requirements.

Condition of delivery

Hot-rolling+annealing,normalizing+tempering,quenching+tempering,cold-drawn or according to the customer's requirements.

Surface:rough machining,fine machining,polishing,bright,pickling,black or according to the customers’ requirements.

Furnaces for metallurgical processing electrode arc + LF,VD,VOD,ESR,Vacuum consumable electrode.

Ultrasonic inspection 100% ultrasonic inspection for any in perfections or according to the customers’ requirements.

All of our steels can be customized(standard GB, ASTM, JIS, DIN, etc.)

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: Can steel round bars be used in the production of HVAC equipment?

- Yes, steel round bars can definitely be used in the production of HVAC (Heating, Ventilation, and Air Conditioning) equipment. Steel round bars are widely utilized in the manufacturing of various HVAC components such as air ducts, frames, supports, brackets, and other structural elements. Steel is a popular choice in HVAC equipment due to its excellent strength, durability, and resistance to corrosion. Its high tensile strength makes it suitable for handling the mechanical stresses and loads experienced by HVAC systems. Additionally, steel can withstand high temperatures and is non-combustible, making it a safe material for HVAC applications. Overall, steel round bars are widely utilized in the production of HVAC equipment for their reliability, longevity, and performance.

- Q: What is the elongation of a steel round bar?

- The elongation of a steel round bar refers to the amount of lengthening or stretching the bar undergoes when subjected to an applied force or load.

- Q: Can steel round bars be used in the manufacturing of bearings?

- Yes, steel round bars can be used in the manufacturing of bearings. Steel is a common material used for bearing manufacturing due to its high strength, durability, and ability to withstand heavy loads and friction. The steel round bars are typically machined and processed to form the bearing components, such as the inner and outer rings, rollers, or balls, which are then assembled to create the final bearing product.

- Q: Can steel round bars be used for shafts or axles?

- Indeed, shafts or axles can make use of steel round bars. In a multitude of industries, including automotive, machinery, and construction, steel round bars are frequently employed due to their robustness, longevity, and adaptability. Their selection for shafts or axles often stems from their capacity to endure substantial loads, furnish dependable support, and endure wear and tear. By virtue of being machinable and amenable to heat treatment, steel round bars can be customized to meet specific prerequisites, rendering them well-suited for deployment as shafts or axles in a wide range of applications where strength and dependability are paramount, such as vehicles, industrial apparatus, and rotating machinery.

- Q: What are the different types of heat treatment for steel round bars?

- There are several different types of heat treatment methods commonly used for steel round bars. These methods are employed to improve the mechanical properties and overall performance of the steel. The most commonly used heat treatment processes for steel round bars include annealing, normalizing, quenching, tempering, and case hardening. 1. Annealing: This heat treatment process involves heating the steel round bars to a specific temperature and then slowly cooling them to room temperature. Annealing helps in reducing internal stresses, improving machinability, and increasing ductility. 2. Normalizing: In normalizing, the steel round bars are heated to a temperature above the critical range and then allowed to cool in still air. This process helps in refining the grain structure and enhancing the mechanical properties of the steel, such as strength and toughness. 3. Quenching: Quenching involves heating the steel round bars to a high temperature and then rapidly cooling them by immersing them in a quenching medium, such as water, oil, or polymer. This process results in the formation of a hardened microstructure, increasing the hardness and wear resistance of the steel. 4. Tempering: After the quenching process, the steel round bars are subjected to tempering. Tempering involves reheating the quenched steel to a specific temperature and then cooling it in still air. This process reduces the brittleness caused by quenching, increases the toughness of the steel, and helps in relieving residual stresses. 5. Case hardening: This heat treatment process is used to increase the hardness and wear resistance of the outer surface of the steel round bars while maintaining a tough and ductile core. Case hardening involves heating the steel in the presence of a carbon-rich atmosphere or by applying a carbon-rich substance, followed by quenching and tempering. Each of these heat treatment methods has its own advantages and is used based on the desired properties and applications of the steel round bars. It is important to carefully select the appropriate heat treatment process to achieve the desired mechanical properties and performance of the steel.

- Q: Can steel round bars be used for making fuel system components?

- No, steel round bars are not suitable for making fuel system components as they lack the necessary corrosion resistance and compatibility with fuels.

- Q: Can steel round bars be used in the textile industry?

- No, steel round bars are not typically used in the textile industry. Textile manufacturing mainly requires materials such as fibers, yarns, fabrics, and machinery specific to the industry. Steel round bars are more commonly used in construction, engineering, and manufacturing sectors where structural strength is required.

- Q: Can steel round bars be used for hydraulic cylinder applications?

- Certainly, hydraulic cylinder applications can indeed make use of steel round bars. Given their remarkable strength and durability, steel round bars find frequent application in the fabrication of hydraulic cylinders. They exhibit exceptional resistance to impact, corrosion, and wear, rendering them ideal for demanding tasks. Furthermore, steel round bars can be conveniently machined and shaped to meet precise dimensional specifications for hydraulic cylinder components. Consequently, steel round bars enjoy significant popularity when it comes to hydraulic cylinder applications.

- Q: Can steel round bars be used in high temperature applications?

- Yes, steel round bars can be used in high temperature applications. Steel is known for its excellent strength and durability, even at high temperatures. However, the specific type of steel and its composition should be considered to ensure it is suitable for the particular high temperature environment and application. Additionally, proper heat treatment and other measures may be necessary to enhance the steel's resistance to high temperatures and prevent any potential degradation or failure.

- Q: What are the different heat treatment methods for steel round bars?

- Some of the common heat treatment methods for steel round bars include annealing, normalizing, quenching, tempering, and case hardening.

Send your message to us

AISI 4340 Forged Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords