AISI 4130 Alloy Steel Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 4130 Alloy Steel Round Bars

Specification

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

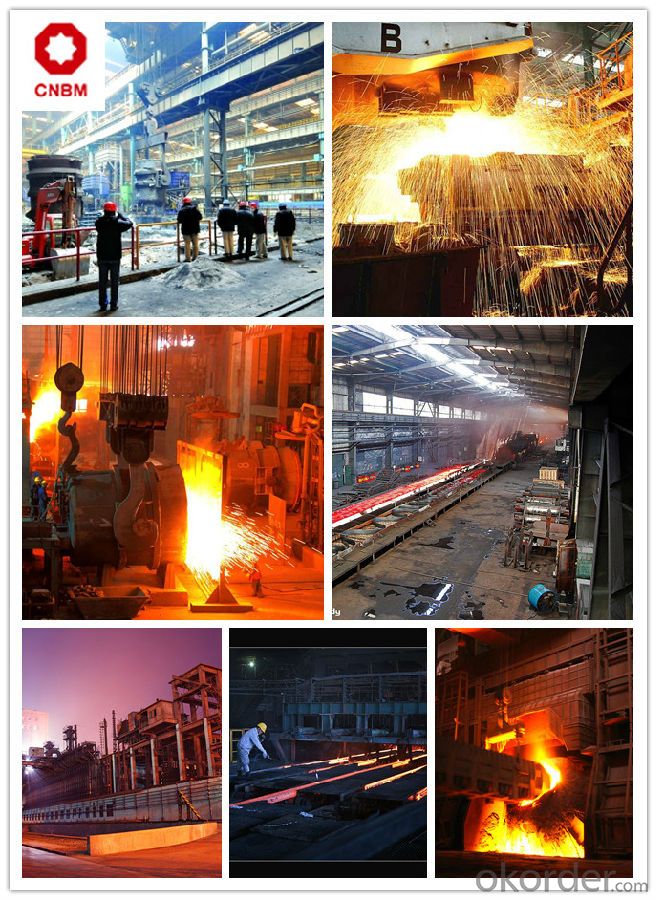

Products Show

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What is the difference between a bright and a precision ground steel round bar?

- A bright steel round bar and a precision ground steel round bar are two different types of steel bars with distinct characteristics and manufacturing processes. The main difference between a bright steel round bar and a precision ground steel round bar lies in their surface finish and manufacturing tolerances. A bright steel round bar, also known as a bright mild steel bar or a bright mild steel round bar, undergoes a process called bright drawing. This process involves pulling the steel bar through a die to achieve a smooth and shiny surface finish. As a result, bright steel round bars have a highly polished appearance and a clean, smooth texture. They are commonly used in decorative applications, such as in the manufacturing of furniture, automotive accessories, and architectural elements. On the other hand, a precision ground steel round bar is manufactured with tight dimensional tolerances and precise surface finishes. These bars are typically made through the process of precision grinding, where the steel bar is machined to achieve a specific diameter and surface finish. Precision ground steel round bars are known for their accuracy and consistency in size, making them suitable for applications that require close tolerance and high precision, such as in the manufacturing of bearings, shafts, and hydraulic cylinders. In summary, the key difference between a bright steel round bar and a precision ground steel round bar lies in their surface finish and manufacturing tolerances. A bright steel bar has a polished appearance and is used primarily for decorative purposes, while a precision ground steel bar is machined to precise dimensions and is suitable for applications that require high precision and close tolerances.

- Q: How to make the round welds on flat steel flat and qualified?

- If it is full weld, for strong, don't groove. There must be no problem with the welding. If you hit the groove, it will deform. When welding, you should do spot welding and diagonal welding. I think you should be able to understand this, but I don't know what you are using for it,

- Q: Can steel round bars be used for hydraulic applications?

- Indeed, hydraulic applications do permit the use of steel round bars. Renowned for its robustness and endurance, steel proves a fitting substance for hydraulic systems demanding intense pressure and substantial burdens. Steel round bars facilitate the production of diverse hydraulic constituents, including cylinders, pistons, shafts, and valves. Moreover, steel's sturdiness and resistance to corrosion render it an unwavering option for hydraulic applications wherein the fluid may harbor impurities or undergo elevated temperatures. Nonetheless, it remains crucial to ponder over the specific prerequisites of the hydraulic application and meticulously choose the grade and type of steel round bars to ensure supreme performance and longevity.

- Q: Are steel round bars suitable for use in the construction of bridges?

- Indeed, steel round bars prove to be a suitable choice for the construction of bridges. Offering a multitude of advantages, they are an ideal option for such projects. To begin with, steel round bars exhibit remarkable tensile strength, enabling them to withstand substantial loads and forces without undergoing deformation or breakage. This attribute holds paramount importance for bridges, as they bear the weight of vehicles and pedestrians. By possessing high tensile strength, steel round bars ensure the structural integrity and safety of the bridge. Furthermore, steel round bars boast exceptional durability and resistance to corrosion. Considering the exposure of bridges to adverse environmental conditions like rain, snow, and saltwater, materials employed in their construction are susceptible to corrosion and deterioration. However, steel round bars are specifically designed to counteract these effects, guaranteeing the longevity and dependability of the bridge. Moreover, steel round bars are widely available in various sizes and lengths, catering to the versatility and adaptability required for different bridge designs and configurations. The uniform circular shape of these bars simplifies the construction process, enabling easy cutting, bending, and welding to meet the necessary specifications. In addition, steel round bars offer cost-effectiveness in bridge construction. Their favorable strength-to-weight ratio allows them to provide the required strength while minimizing the overall weight of the bridge. Consequently, this reduces the amount of material needed and lowers transportation costs during construction. In conclusion, steel round bars are highly suitable for bridge construction due to their high tensile strength, durability, corrosion resistance, versatility, and cost-effectiveness. They deliver the necessary strength and reliability to support heavy loads and withstand adverse environmental conditions, ensuring the safety and durability of the bridge.

- Q: What are the options for joining steel round bars?

- There are several options for joining steel round bars, depending on the specific requirements and applications. Some common methods include welding, bolting, and adhesives. 1. Welding: Welding is a widely used method for joining steel round bars. It involves melting the ends of the bars and fusing them together using a welding process such as arc welding, MIG welding, or TIG welding. Welding provides a strong and durable joint that can withstand high loads and stresses. 2. Bolting: Bolting involves using bolts, nuts, and washers to join steel round bars. Holes are drilled through the bars, and bolts are inserted through these holes. The nuts are then tightened to secure the bars together. Bolting is a relatively simple and quick method, and it allows for disassembly and reassembly if required. 3. Adhesives: Adhesives can also be used to join steel round bars. High-strength industrial adhesives are applied to the mating surfaces of the bars, which are then pressed together and left to cure. Adhesive bonding can provide a strong and durable joint, particularly in applications where welding or bolting may not be feasible or desired. 4. Mechanical couplings: Mechanical couplings are specifically designed for joining steel round bars. These couplings typically consist of two separate components that are fitted over the ends of the bars and tightened together using screws, clamps, or other mechanical means. Mechanical couplings provide a reliable and secure joint without the need for welding or drilling. 5. Cold forming: In some cases, steel round bars can be joined through cold forming techniques such as swaging or crimping. These methods involve mechanically deforming the ends of the bars to create a tight and secure joint. Cold forming is often used in applications where welding or other traditional methods are not suitable. It is important to consider the specific requirements, load-bearing capacities, and environmental conditions when selecting the appropriate method for joining steel round bars. Consulting with a professional engineer or welder can help determine the best option based on the specific application and desired outcome.

- Q: What are the different surface treatments available for stainless steel round bars?

- To enhance the appearance, improve corrosion resistance, and provide added protection for stainless steel round bars, there are various surface treatments available. Some commonly used surface treatments for stainless steel round bars are as follows: 1. Acid immersion: This process involves immersing the stainless steel bar in an acid solution to eliminate surface impurities and oxides. Acid immersion restores the natural corrosion resistance of stainless steel and results in a smooth and clean surface. 2. Chemical passivation: Passivation is a chemical treatment that forms a thin, protective layer on the surface of stainless steel. By eliminating free iron and other contaminants, passivation enhances the corrosion resistance of stainless steel. 3. Electrolytic polishing: This treatment involves immersing the stainless steel round bar in an electrolyte solution and applying an electric current. By removing a thin layer of material from the surface, electrolytic polishing creates a smooth, shiny, and corrosion-resistant finish. 4. Mechanical grinding and polishing: Grinding and polishing are mechanical processes used to improve the surface finish of stainless steel round bars. Grinding eliminates imperfections and roughness, while polishing creates a smooth and reflective surface. 5. Protective coating: Applying a protective layer to stainless steel round bars can provide additional corrosion resistance. Common coatings include electroplating with zinc or nickel, as well as organic coatings such as paints or powder coatings. 6. High-velocity shot blasting: This treatment involves bombarding the surface of the stainless steel round bar with small metallic or non-metallic particles at high speed. Shot blasting eliminates surface contaminants, scales, or oxides, resulting in a clean and textured surface. It is important to consider the desired end-use application and specific requirements for appearance and corrosion resistance when choosing a surface treatment for stainless steel round bars. Seeking advice from professionals or manufacturers can help determine the most suitable treatment.

- Q: Are steel round bars resistant to corrosion?

- Yes, steel round bars can be resistant to corrosion depending on the type of steel and the environment they are exposed to. Stainless steel round bars, for example, contain chromium which forms a thin passive layer on the surface that protects against corrosion. This layer is self-repairing and provides excellent resistance to corrosion in many environments, including moisture, chemicals, and saltwater. However, carbon steel round bars are not inherently corrosion-resistant and may require additional protective coatings or treatments to prevent corrosion. Therefore, it is important to consider the specific type of steel and the intended application when determining the corrosion resistance of steel round bars.

- Q: Can steel round bars be used for making springs?

- Yes, steel round bars can be used for making springs. Steel is a commonly used material for springs due to its strength, durability, and flexibility. Round bars can be machined and shaped into the desired form for different types of springs, making them suitable for various applications.

- Q: What are the different types of steel round bar alloys for improved machinability and strength?

- Improved machinability and strength can be achieved with several variations of steel round bar alloys. These alloys are designed specifically for industries where efficient machining and high tensile strength are essential. Here are some of the popular alloys used: 1. 12L14: This alloy incorporates lead, functioning as a lubricant during machining. This results in improved chip formation and reduced tool wear. Its exceptional machinability and good strength make it ideal for applications involving intricate machining processes. 2. 4140: Known as "chromoly" steel, this alloy contains chromium and molybdenum, which enhance its strength and hardenability. It is extensively used in applications that demand high tensile strength, such as automotive parts, shafts, and gears. 3. 8620: This low-alloy nickel-chromium-molybdenum steel offers a combination of high strength and good toughness. It can be easily machined and is commonly employed in case-hardening applications like gears, shafts, and fasteners. 4. 1018: Referred to as "cold-rolled" or "cold-finished" steel, 1018 is a low-carbon alloy with good machinability and weldability. It finds common usage in applications requiring precise and smooth finishes, such as bolts, screws, and hydraulic fittings. 5. 52100: This high carbon, chromium-bearing steel is primarily used for manufacturing bearings and other high-wear applications. It offers excellent hardness, wear resistance, and machinability, making it suitable for components necessitating strength and durability. These examples illustrate the range of steel round bar alloys available to enhance machinability and strength. The choice of alloy depends on specific application requirements, including desired strength, machinability, and durability. Consulting with a materials engineer or supplier can assist in identifying the most suitable alloy for a particular use case.

- Q: What are the different types of defects that can occur in steel round bars?

- Some common types of defects that can occur in steel round bars include surface defects such as cracks, pits, and scratches, as well as internal defects like inclusions, segregation, and porosity. Additionally, steel round bars can also experience dimensional defects such as ovality, taper, and straightness issues.

Send your message to us

AISI 4130 Alloy Steel Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords