80% alumina 1-3mm calcined bauxite with low price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

80% alumina 1-3mm calcined bauxite with low price

Specifications of 80% alumina 1-3mm calcined bauxite

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Our Advantages of 80% alumina 1-3mm calcined bauxite

1. We have substantial experience for material manufacture and export.

2. We establish a long-term relation of cooperation with raw material supplier, so we can offer you the best quality and price.

3. We have equipped 8 production lines and skilled workers to make the quality best.

4. We can control strictly quality at factory and third party testing institutions quality inspection.

5. We can also offer you the related test report, both at factory and the third party testing institutions.

6. We have sufficient manufacturing capability to deliver the goods safely and timely.

7. We can pack in 25kg bags, 1mt big bags, 1.25mt big bags or as your request. We can also pack with pallet.

8. We have professional service team keep customers informed from delivery to discharge.

Product Description of 80% alumina 1-3mm calcined bauxite

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Usage of 80% alumina 1-3mm calcined bauxite

1. aluminium industry.

2 . precision casting.

3. for refractory products

4. aluminum silicate refractory fiber.

5. with magnesia and bauxite clinker as raw material, add appropriate binder, used for pouring ladle whole ladle lining has particularly good effects.

6. manufacture alumina cement, abrasive materials, ceramic industry and chemical industry of aluminum compounds

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

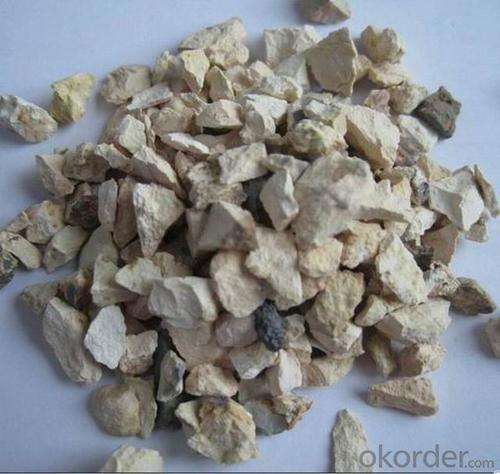

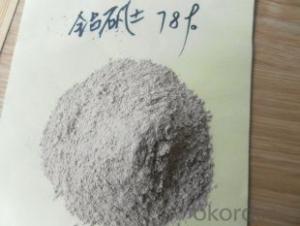

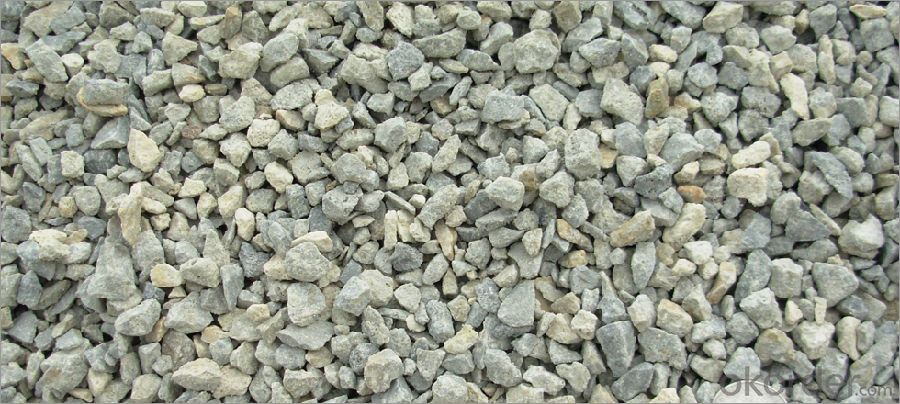

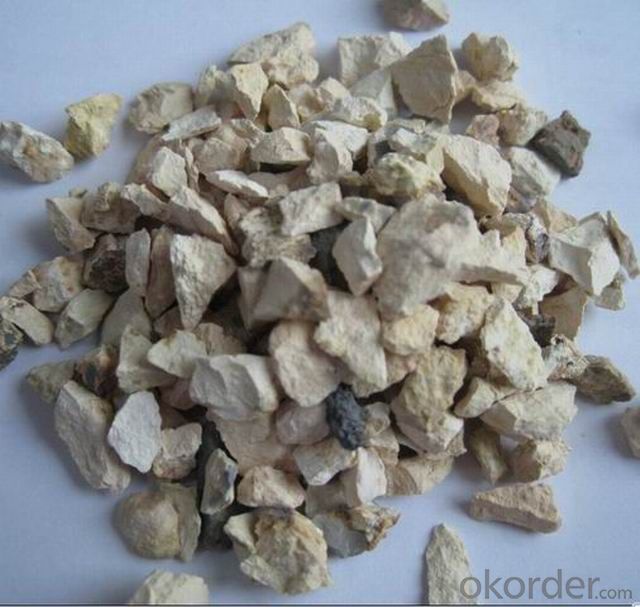

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What's the fire?retardant material of roller shutter fire resistance door ?

- It is composited by inorganic materials, and main componets are perlite and inorganic adhesive, etc.

- Q: Who can tell me what is neutral refractory?

- Refractories mainly refer to aluminum oxide, chromium oxide and carbon as the main component of refractory materials, such as corundum brick, high alumina brick, and carbon brick. Its characteristic goes to the resistance to both acidic and basic slag. Basic refractories mainly refer to the refractory materials whose mian components are magnesium oxide and calcium oxide, including magnesia bricks, magnesia-alumina bricks, magnesia chrome bricks, dolomite bricks, etc. Basic refractory is good at resisting basic slag erosion.

- Q: How is the division of the fire resistant level of the rock wool board?

- It's like this: China's national standard GB8624-97 divides the combustion performance of building materials into the following grades. Level A: non-flammable building materials. Level B1: flame-retardant building materials. Level B2: combustible?building?materials. Level B3 flammable building materials. section II Combustion performance and fire endurance of building components. First, The combustion performance of buildings of building components. The building is composed of components, such as foundation, walls, lubrication columns, beams, plates, roofs and stairs, ect. Building components are constituted by the building materials, whose combustion performance depends on the combustion properties of the used construction materials. Section One Combustion performance of building components. The building components are divided into three categories according to their combustion properties. First, non-combustible component: the component made by incombustible?materials. The incombustible?material refers to that when meeting the Oxygen in the air, it will not burn.

- Q: Application of refractory materials in petroleum industry

- Our natural gas transportation, chemicals, equipment, packing, safety, insulation, and even building materials are available.

- Q: what is the requirements of roofing insulation materials fire rating?

- The fireproofing requirements of architectural design are regulated by architectural design fire?safety?rules, roofing insulation material only has the requirements of materials combustion performance, namely non-combustible material. No fire rating requirements.

- Q: What is the material composition of the new fire-resistant coating?

- New fire?retardant?coating materials are produced by non-toxic expanding materials and special process, with no pollution. Use natural bite when installing, without using the formaldehyde and other toxic glue. It consists of a variety of organic matters, so it adapts to the natural environment, with long time of fire-resistant; The fire-resistant time for new fire retardant module is up to 4 hours or more, three hours more than the standard prescribed by the state. It is composed by the specially formulated materials, with no flying smoke, good heat insulation effect, fast heat dissipation, scientific and rational design, easy using and no falling off and long period of effective.

- Q: Which kind of furnace hearth refractory is better?

- hearth selected material] hearth material must be durable, high temperature resistant, general selecting masnory made of refractory cement, silicon carbide refractory products, mullite or multicrystal mullite (which is the general term of minerals composed of a series of aluminum silicate, mullite is only stable binary compound in the Al2O3-SiO2 system) etc.. [hearth] is a three-dimensional space surrounded by furnace walls for combustion of the fuel. The funtion of hearth is to ensure the fuel to burn as far as possible, and to cool the gas temperature of the hearth exit to the allowed temperature of convection heating surface safe operation . Therefore, the hearth should have sufficient space and adequate heating surface. In addition, there should be reasonable shape and size in order to fit the burner and the organize aerodynamic field inside the furnace to prevent the flame from adherence, dashing walls and have high fullness and eve wall thermal load.

- Q: How should fireproof building materials be ranked?

- 5. Civil building 5.1. Fire resistance rating, number of layers and floorage of civil buildings 5.1.1. Fire resistance rating of civil buildings should be classified into four levels of first, second, third and fourth. Unless otherwise specified in the code, the combustion performance and fire endurance of building components with different fire resistance rating should be no less than that of the regulations in Table 5.1.1. Table 5.1.1: Combustion Performance and Fire Endurance (h) of Building Components (Figure) Note: 1. Unless otherwise specified in the Code, the fire resistance rating of the building with wooden pillars as load-bearing and incombustible material as the building wall should be the fourth level; 2. For the suspended ceiling of the building with the second level of fire resistance rating, if it uses non-combustible component, it won't be limited in its fire endurance; 3. For buildings with the second level of fire resistance rating, if it is really difficult for the partition wall of rooms with the area of no less than 100m2 to implement the regulations of the Table, the partition wall can adopt the non-combustible component with fire endurance of no less than 0.3h; 4. For buildings with the first or second level of fire resistance rating, if it is really difficult for the partition wall of both sides of the evacuation walk to implement the regulations of the Table, the partition wall can adopt the non-combustible component with fire endurance of no less than 0.75h. 5. Fire endurance and combustion performance of the residential building component can be implemented in accordance with the provisions of current national standard GB 50368 "Residential Building Code".

- Q: How many fire endurance grades are the AAA fire resisting shutter divided?

- According to the fire endurance, the fire doors can be divided into Class A, Class B and Class C fire doors with the fire resistances are not less than 1.20h, 0.90h and 0.60h. Even the fire resistant level of B can also use the first rate fire resistant door.

- Q: Does anyone know the fire endurance of steel stud partition?

- The fire endurance degree is 1 hour. which is in line with the national building material fireproofing test standards. CaSo4.2H2O is molecular gypsum molecular structure formula, containing 20% ??water, crystal water and free water, when putting on fire, 10% of the surface water will slowly evaporate, remaining10% of crystal water. It is a class A fire retardant material itself. The longest time can be 4 hours.

Send your message to us

80% alumina 1-3mm calcined bauxite with low price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords