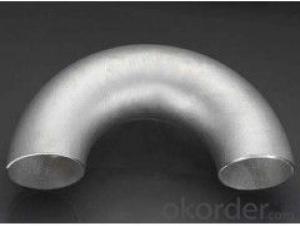

60 Degree Aluminum Tile Trim Profiles Elbow for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

60 degree aluminum elbow:

Material : carbon steel , stainless steel and alloy steel,

60 degree aluminum elbow

Specifications

ASTM B16.9 A234 WPB 90degree 1.5D carbon steel elbow

1.A234 WPB elbow

2.size:1/2"-72"

3.material:A234 WPB

4.API CE ISO

ASTM B16.9 A234 WPB 90degree 1.5D carbon steel elbow

1.A234 WPB elbow

2.size:1/2"-72"

3.material:A234 WPB

4.API CE ISO

Size | 1/2''-24 seamless elbow 26''-72''butt weld elbow |

Wall Thickness | SCH10-SCH160,STD,XS,XXS, GOST , DIN, JIS standard thickness |

Standard | ASTMA234,ASTM A420,ANSI B16.9/B16.28/B16.25,ASME B16.9, JIS B2311-1997/2312, JIS B2311/B2312, DIN 2605-1/2617/2615, GB 12459—99,GOST,EN Standard etc. |

Material | Q235, 20#, 10#, Q345 A234 WPB, WP5, WP9,WP11, ST37.0,ST35.8,ST37.2,ST35.4/8,ST42,ST45,ST52,ST52.4 STP G38,STP G42,STPT42,STB42,STS42,STPT49,STS49 |

Application | Low and middle pressure fluid pipeline,boiler, petroleum and natural gas industry,drilling,chemical industry, electric industry,shipbuilding, fertilizer equipment and pipeline, structure,petrochemical, pharmaceutical industry |

Surface | Sand blasting, black anti-rust oil or galvanized , 3PE,etc. |

Package | Seaworthy Package, Plastic film,Ptywood Wooden Cases or wooden pallet or |

Certificate | ISO9001:2008, CE, API , SGS,BV, etc |

Capacity | 50000tons/year |

Advantages | 1.Reasonable price with excellent quality 2.Abundant stock and prompt delivery 3.Rich supply and export experience, sincere service 4. Reliable forwarder, 2-hour away from port. |

- Q: What are the fireproofing properties of aluminum profiles?

- Aluminum profiles have excellent fireproofing properties, making them a popular choice for various applications. Aluminum is a non-combustible material, meaning it does not burn or contribute to the spread of fire. Aluminum profiles have a high melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), which is significantly higher than most flammable materials. This property allows aluminum to withstand high temperatures without losing its structural integrity or igniting. Furthermore, aluminum naturally forms a protective oxide layer on its surface, which acts as a barrier against heat and flames. This oxide layer provides additional fire resistance by preventing direct contact between the aluminum and the fire source. In the event of a fire, aluminum profiles can help to contain and limit the spread of flames as they do not release combustible gases or produce toxic fumes. This makes them a safe choice for applications where fire safety is a priority, such as in the construction of buildings, transportation vehicles, and industrial equipment. Overall, the fireproofing properties of aluminum profiles make them a reliable and durable material in fire-prone environments, providing peace of mind in terms of safety and protection.

- Q: What are the surface hardness properties of aluminum profiles?

- The surface hardness properties of aluminum profiles can vary depending on the specific alloy and treatment processes applied. Aluminum alloys are generally known for having a lower hardness compared to other metals such as steel. However, through various treatments, aluminum profiles can achieve improved surface hardness. One common treatment method is anodizing, which involves creating an oxide layer on the surface of the aluminum. This process not only enhances the corrosion resistance of the profiles but also increases their surface hardness. Anodized aluminum profiles can have a hardness ranging from 150 to 300 HV (Vickers hardness), depending on the thickness of the oxide layer. Another treatment process is hard coating, where a ceramic material such as aluminum oxide is applied to the surface of the profiles. This coating significantly enhances the hardness of the aluminum, providing a greater level of wear resistance. The hardness of hard-coated aluminum profiles can range from 400 to 600 HV or even higher. It is important to note that the specific hardness properties can vary depending on the alloy composition, surface treatment method, and the desired application of the aluminum profiles. Therefore, it is crucial to consult with manufacturers or suppliers to determine the appropriate hardness properties that best suit your specific needs.

- Q: Are aluminum profiles suitable for swimming pool enclosures?

- Yes, aluminum profiles are suitable for swimming pool enclosures. Aluminum is a durable and lightweight material that is resistant to corrosion, making it ideal for outdoor applications like swimming pool enclosures. It offers strength and stability while also being low maintenance and easy to clean. Additionally, aluminum profiles can be customized to fit specific design requirements, providing a wide range of options for swimming pool enclosure construction.

- Q: This question asks about the variety of dimensions and forms that aluminum profiles can come in.

- <p>Aluminum profiles are available in a wide range of sizes and shapes to suit various applications. Common shapes include rectangular, square, circular, and special profiles like angles, channels, and tees. Sizes can vary from thin strips to thick bars, with specific dimensions tailored to the needs of the project. The profiles can be flat, hollow, or have complex cross-sectional geometries. They are also available in different surface finishes, such as anodized, painted, or powder-coated, to enhance their appearance and durability. The selection of aluminum profiles depends on the structural requirements, design specifications, and the industry they are intended for, such as construction, automotive, or aerospace.</p>

- Q: How do you prevent discoloration or fading of aluminum profiles?

- There are several steps that can be taken to prevent discoloration or fading of aluminum profiles: 1. It is crucial to clean aluminum profiles regularly in order to eliminate any dirt, dust, or contaminants that may cause discoloration or fading. This can be accomplished by using a mild detergent or a specialized aluminum cleaner, followed by rinsing with clean water. 2. Avoid using harsh or abrasive cleaners that can harm the surface of aluminum profiles, resulting in discoloration or fading. It is important to utilize gentle cleaning products specifically designed for aluminum. 3. Applying a protective coating to the surface of aluminum profiles can help prevent discoloration and fading. There are various types of coatings available, such as clear coats or anodizing, which create a protective barrier against environmental factors. 4. Protect aluminum profiles from prolonged exposure to harsh elements, such as direct sunlight, extreme temperatures, or chemicals. These factors can accelerate the process of discoloration or fading. If the profiles are installed outdoors, consider providing sufficient shading or protective covers to minimize exposure. 5. Regularly inspect and maintain aluminum profiles to identify any early signs of discoloration or fading. Promptly addressing any issues, such as scratches or surface damage, can prevent further deterioration. 6. If aluminum profiles are not immediately installed, it is important to store them in a dry and well-ventilated area, away from moisture or direct sunlight. Proper storage can help preserve the integrity of the profiles and prevent premature discoloration or fading. By following these preventive measures, it is possible to extend the lifespan and maintain the aesthetic appeal of aluminum profiles, reducing the risk of discoloration or fading.

- Q: This question asks about the various surface treatments or finishes that can be applied to aluminum profiles used in window and door frames.

- <p>Aluminum profiles used for windows and doors can have several finishes to enhance their appearance and durability. These include anodizing, which creates a protective oxide layer; powder coating, offering a wide range of colors and textures; thermal spraying, which applies a coating to improve resistance to wear; and electrophoretic coating, which provides a smooth, even finish. Additionally, there are finishes like polishing for a shiny look, brushing for a matte appearance, and wood grain transfer for a natural aesthetic. Each finish serves a specific purpose, from enhancing visual appeal to providing corrosion resistance and UV protection.</p>

- Q: Is it possible to recycle aluminum profiles and repurpose them for different uses?

- <p>Yes, aluminum profiles can be recycled and reused in other applications. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for a variety of new applications, such as construction, automotive, and consumer goods. The recycling of aluminum profiles not only conserves resources but also reduces waste and environmental impact.</p>

- Q: 80 series insulation aluminum broken bridge 1.4 thick, one square kilogram, how many kilograms aluminum material?

- Each brand of profiles, aluminum weight is not the same, but within the unit area is about 8 kilograms, little difference

- Q: Can aluminum profiles be customized according to specific requirements?

- Indeed, specific requirements can be accommodated through the customization of aluminum profiles. This adaptable material can be effortlessly manipulated, trimmed, and formed to adhere to diverse design specifications. The dimensions, shape, thickness, and surface finish of aluminum profiles can all be personalized. Furthermore, drilling, bending, welding, and powder coating are additional processes that can be employed to further tailor aluminum profiles, achieving desired functionality and aesthetic allure. Such customizability renders aluminum profiles fitting for an extensive array of applications across industries, including construction, automotive, aerospace, and electronics.

- Q: This question asks for methods to prevent rusting on aluminum profiles during the installation process.

- <p>To prevent rusting on aluminum profiles during installation, follow these steps: Ensure the aluminum profiles are clean and free from any contaminants before installation. Use stainless steel screws and fittings to avoid galvanic corrosion. Keep the profiles dry and avoid contact with moisture. Apply a protective coating or sealant if the profiles will be exposed to harsh environments. Store aluminum profiles in a dry place to prevent moisture absorption. Regularly inspect and maintain the profiles to catch any signs of corrosion early.</p>

Send your message to us

60 Degree Aluminum Tile Trim Profiles Elbow for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords