430 Mirror finishing Stainless Steel Sheet made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. | Item | Stainless steel sheets / stainless steel plates | ||

2. | Standard | ASTM,AISI,GB,JIS,SUS,EN,DIN,etc. | ||

3. |

Material | 200 series | 300 series | 400 series |

201,202 | 300,301,304,304L,309S,310S,316Ti,316L, 317L,321,329,329LA,329LD | 409,410,430,430LX,600,601 | ||

4. |

Specification | Thickness | 0.3mm-20mm | |

Width | 1000/1200/1219/1220/1250/1500/1800mm | |||

Length | 2000/2500/3000/6000mm | |||

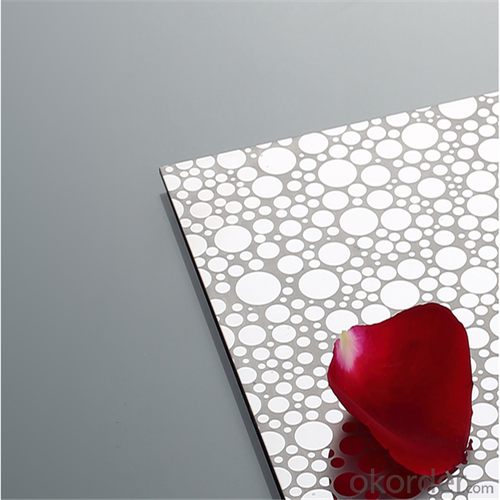

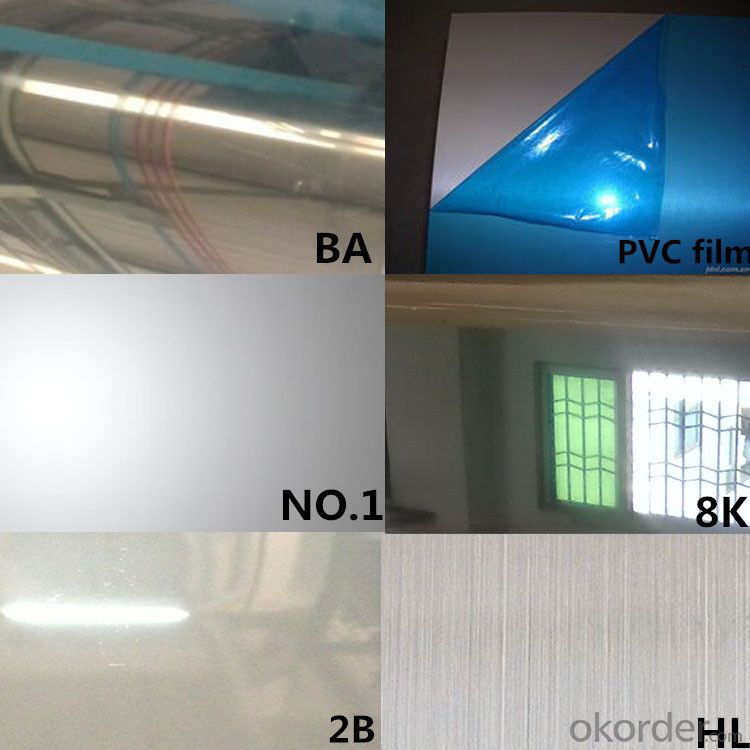

5. | Surface finished |

2B/BA/HAIRLINE/8K/NO.1/NO.4 | ||

6. | Techinque | Cold rolled/ hot rolled | ||

7. |

Application | Stainless steel sheets are widely used in below fields:

1:Chemical industry equipment,industrial tanks 2:Medical instruments,tableware,kitchen utensil,kitchen ware. 3:Architectural purpose,milk or food processing facilities. 4:Hospital equipment,interior exterior decoration for building 5:Architectural purposes,escalators,kitchen ware,vehicles.

Or they can be made as your requirement. | ||

8. | Package | Standard export package. | ||

9. | Market | Asia,Africa,Europe,Middle East,South and North America,Oceania,etc | ||

Surface finished | Definition &Application | |

2B | Those finished,after cold rolling, by heat treatment,picking or other equivalent treatment and lastly by cold rolling to given appropriate luster | Medical equipment, construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling | Kitchen utensils, Electric equipment, Building construction. |

No.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001 | Kitchen utensils, Building construction. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building construction |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling | Chemical tank pipe |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. | |

Packaging & Shipping

Packing details | 5000 Ton/Tons per Month |

Delivery Time | 7-15 working days |

Payment Terms | L/C ,T/T , western union , paypal , alipay |

Shipping | By container |

Our Services

1) offer free samples

2) welcome to visit our factory

3) make logo on the surface of the product according to customer's demand

4) all enquiries will be treated carefully and be replied soon

- Q: Can stainless steel sheets be used for elevator floors?

- Yes, stainless steel sheets can be used for elevator floors. Stainless steel is a durable and hygienic material that is resistant to corrosion and staining, making it a suitable choice for elevator flooring.

- Q: Can stainless steel sheets be used for wall cladding?

- Yes, stainless steel sheets can be used for wall cladding. Stainless steel is a durable and long-lasting material that is resistant to corrosion, making it a suitable choice for cladding applications. It provides a sleek and modern appearance, adding an aesthetic appeal to the walls. Stainless steel sheets can be easily installed and maintained, making them an excellent option for both interior and exterior walls. Additionally, stainless steel sheets offer excellent fire resistance and can withstand high temperatures, making them a safe choice for wall cladding.

- Q: How do stainless steel sheets differ from other types of metal sheets?

- There are several ways in which stainless steel sheets are different from other types of metal sheets. To begin with, stainless steel is an alloy that contains at least 10.5% chromium. This chromium content creates a protective layer of chromium oxide on the metal's surface, giving it a high resistance to corrosion and staining. This sets stainless steel sheets apart from other metals as they can endure exposure to harsh environments, chemicals, and moisture without deteriorating. Additionally, stainless steel sheets provide excellent strength and durability. Due to their composition, they are highly resistant to heat, impact, and wear. This makes them suitable for a wide range of applications, including automotive, construction, and industrial settings, where strength and endurance are crucial. Another significant difference is the aesthetic appeal of stainless steel sheets. They have a modern and sleek appearance that is highly sought after in architectural and interior design projects. Stainless steel sheets can be easily polished to achieve a mirror-like finish, adding an elegant touch to any space. Furthermore, stainless steel sheets are known for their hygiene and cleanliness. They have a non-porous surface that does not absorb moisture, making them resistant to bacteria, mold, and other contaminants. This makes stainless steel sheets the preferred material for kitchen appliances, food processing equipment, and medical devices. Lastly, stainless steel sheets offer high levels of customization. They can be manufactured in various thicknesses, sizes, and finishes to meet specific requirements. Additionally, stainless steel can be easily formed, welded, and fabricated, allowing for creative designs and customization options. In conclusion, stainless steel sheets stand apart from other metal sheets due to their exceptional corrosion resistance, strength, durability, aesthetic appeal, hygiene, and customization options. These unique characteristics make stainless steel sheets a versatile and reliable choice for a wide range of applications.

- Q: What type of welding rod is used for 304 stainless steel plate welding?

- The selection of reference electrode parent material, selection and composition of base metal electrode in the same or similar; owing to the great influence of carbon content on corrosion resistance of stainless steel, stainless steel weld metal carbon content is higher than that of base material.

- Q: Can stainless steel sheets be used for automotive body panels?

- Yes, stainless steel sheets can be used for automotive body panels. Stainless steel provides excellent corrosion resistance, durability, and aesthetic appeal, making it a suitable material for automotive applications.

- Q: How do you straighten bent stainless steel sheets?

- Depending on the severity of the bend, there are several methods available for straightening bent stainless steel sheets. 1. For slight bends, a rubber mallet or hammer can be used to gently tap the bent area back into place. Gradually apply even pressure, starting from the center of the bend and moving towards the edges. It is important to avoid striking the stainless steel too forcefully, as this could cause further damage. 2. In cases of more severe bends, heat can be used to soften the stainless steel, making it easier to straighten. Begin by heating the bent area using a blow torch or heat gun. Once the stainless steel reaches a red-hot temperature, carefully use pliers or a vice grip to straighten the sheet. It is important to note that this method is most suitable for thicker stainless steel sheets, as thinner ones may warp or lose their shape when exposed to excessive heat. 3. For larger or heavy-duty sheets that cannot be easily straightened by hand, mechanical straightening is recommended. This involves using specialized tools like a hydraulic press or metal brake to apply controlled pressure and straighten the bent stainless steel sheet. It is crucial to carefully follow the manufacturer's instructions when using these tools to prevent accidents. Always wear appropriate safety gear, such as gloves and eye protection, when working with stainless steel sheets. If you are unsure or uncomfortable with straightening the sheets yourself, it is advisable to seek assistance from a professional metalworker or fabrication shop.

- Q: What does stainless steel plate mean?

- The stainless steel plate is divided into two kinds of hot-rolled and cold-rolled parts according to the method of manufacture, including the thickness of 0.02-4 mm thin cold plate and 4.5-50 mm medium plate. According to the structural characteristics of steel, they can be divided into 5 types: austenite type, austenite ferrite type, ferrite type, martensite type and precipitation hardening type. Can withstand oxalic acid, sulfuric acid iron sulfate, nitrate, nitrate acid and hydrofluoric acid, sulfuric acid copper sulfate, phosphoric acid, formic acid and acetic acid and various acid corrosion, widely used in chemical, food, medicine, papermaking, petroleum, atomic energy industry, as well as construction, kitchen utensils, cutlery, household appliances, vehicles of all kinds of parts. In order to ensure the mechanical properties of various kinds of stainless steel sheet, such as yield strength, tensile strength, elongation and hardness, the steel plate must be annealed, treated by solution, aging treatment before delivery.

- Q: What is the minimum thickness of stainless steel sheets available?

- The minimum thickness of stainless steel sheets available can vary depending on the manufacturer and the specific grade of stainless steel being used. Generally, the thinnest stainless steel sheets available range from 0.4mm to 0.5mm. However, it is important to note that some manufacturers may offer thinner sheets, such as 0.3mm, but these may be more specialized or less commonly available. If you require a specific thickness for your project, it is recommended to consult with stainless steel suppliers or manufacturers to determine the options available to you.

- Q: What are the different types of textured patterns available for stainless steel sheets?

- There are several types of textured patterns available for stainless steel sheets, including diamond, quilted, linen, and checkerplate patterns.

- Q: What are the advantages of using stainless steel sheets in the aerospace industry?

- Using stainless steel sheets in the aerospace industry has several advantages. Firstly, stainless steel is renowned for its remarkable strength and durability. It can endure high temperatures and extreme conditions, making it perfect for aircraft components that require superior performance and long lifespan. This strength allows stainless steel sheets to resist corrosion, which is crucial in an industry where safety is paramount. Secondly, stainless steel sheets offer excellent resistance to impact and fatigue. This is particularly important in the aerospace sector, where components are constantly subjected to vibrations and stress. Stainless steel can absorb these forces without compromising its structural integrity, ensuring the safety and reliability of the aircraft. Thirdly, stainless steel sheets possess a high strength-to-weight ratio, making them lightweight yet strong. This is essential in aviation, where reducing weight is a primary concern for fuel efficiency and overall performance. By utilizing stainless steel sheets, aircraft manufacturers can achieve the desired strength without adding unnecessary weight, leading to improved fuel economy and increased payload capacity. Furthermore, stainless steel sheets are highly versatile. They can be easily formed, welded, and machined into intricate shapes and sizes, allowing for the production of complex aerospace components. This versatility enables engineers to design and manufacture innovative aircraft parts, resulting in improved aerodynamics, reduced drag, and enhanced overall performance. Lastly, stainless steel sheets exhibit excellent heat resistance properties. They can endure high temperatures without losing their strength or shape, making them ideal for applications that involve exposure to extreme heat, such as jet engines or exhaust systems. This heat resistance ensures the longevity and reliability of these critical components, contributing to the overall safety and efficiency of aircraft. In conclusion, the advantages of using stainless steel sheets in the aerospace industry include exceptional strength and durability, resistance to impact and fatigue, high strength-to-weight ratio, versatility in manufacturing complex components, and excellent heat resistance properties. These qualities make stainless steel sheets an optimal choice for aircraft manufacturers, guaranteeing the safety, reliability, and efficiency of aerospace vehicles.

Send your message to us

430 Mirror finishing Stainless Steel Sheet made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords