33112 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

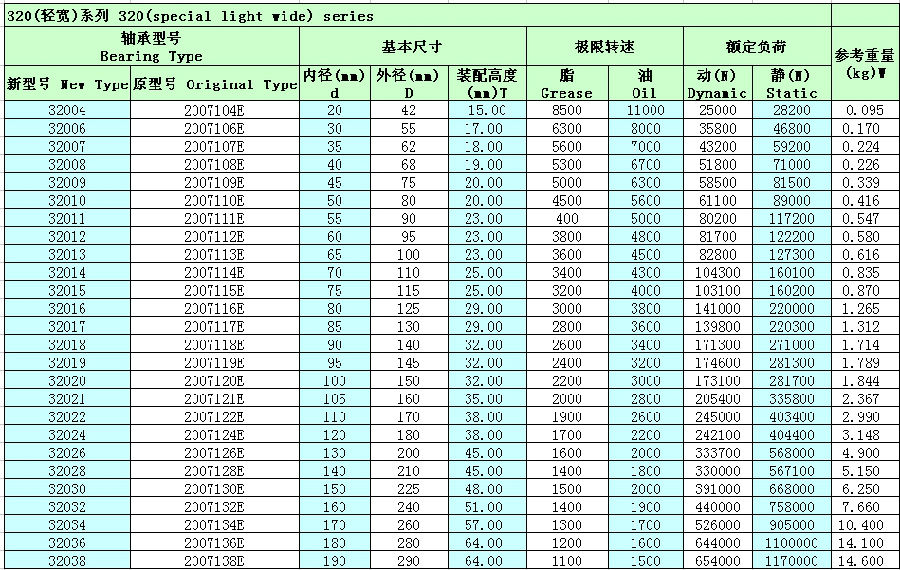

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q: What is the size of tapered roller bearings 352214?

- Bearing type: tapered roller bearingNew model: 352214Old model: 97514EInternal diameter (mm):70Outside diameter (mm):125Width (mm):75

- Q: The roller of tapered roller bearings is cylindrical or cylindrical body? Why roller drawing method of drawing section for the rectangular (here I want to add: I have seen the N version, some of the paintings is rectangular, trapezoidal and some paintings, 2 versions, a few of my book is that the proportion is A/2 the roller projection) it indicates that the real roller should be a cylinder or a cylindrical body roller is... What master?

- Roller tapered roller bearing is a conical body, sometimes drawing simplified painted section cylinder, not misleading (a type of list), is also permitted.-- -- -- -- --

- Q: How does the roller of tapered roller bearings fit in?

- Tapered roller bearings itself can be broken down, and new (or old) bearings are cleaned and decomposed. So do not worry, carefully installed in accordance with the original installation order on the line, and if it does not meet the installation order, the installation of this bearing is not go on.

- Q: Tapered roller bearings 32010x, two matching, how to install?

- The design of this kind of bearings makes the inner ring raceway, outer raceway and the top of each cone face intersect the point of the central line of the roller. In addition to metric series products, there are a variety of English series products.

- Q: you master good! Ask a question about the use of tapered roller bearings: a mechanism using a double row tapered roller bearings, but did not buy this model, can use two single row tapered roller bearing together instead of double row?

- 2, the clamping way is: double row bearing inner ring is double row, or outer ring double, determines when you install the inner ring or outer ring is clamped, clamped, if you want to replace with the two row, when combined with the clearance you need to consider the ring, you should adjust the clearance and is placed on the inner ring, or on the outside, too that depends on your way of clamping;

- Q: There are many kinds of tapered roller bearings, because of work requirements, test the external size is qualified, I want to make a test, to test the bearing is qualified, mainly inside and outside diameter and inside and outside the ring height tolerances, diameter ranging from 50mm--80mm, score less, look forward to your help, I thank you there are 322163311532215 main bearings, 313113002

- Less points, huh, huh?Bearings are tested with a dedicated bearing inspection instrumentTable seat:Outside diameter D913Internal diameter D923Height G904With standard and special micrometer (usually microkators and leverage comparator)Each inspection procedure has the corresponding inspection instructionYou can provide the job instructions free of charge to your bearings suppliers as a project to review their process controlAs for the instrument, you should pay for it even if your supplier offers itIf you buy the bearings in the retailers, then you have to pay for them yourselfThe work instructions may also have to be replaced by money

- Q: Online cylinder cones are GB/T4663, what do you mean?

- Which size do you want, eldest brother? How do I make so much?GB/T: recommended national standards; GB: mandatory national standards4663: taper roller national standard codeThere is a missing release year later!It should be: GB/T 4663-1994

- Q: What is the 30207 judgment coefficient e of tapered roller bearings?

- Your adoption is the driving force of my progress~~O (a O, a _) remember praise and adoption, help each other.

- Q: that is to say, the taper head is the face and the back is the back

- The installation of tapered roller bearings is not only to pay attention to the direction of installation, there are many other places to pay attention to, is a very professional technical activities

- Q: Turbine turbo rod reduction box, tapered roller bearing at both ends of wormGap measuring method, tapered roller bearingsThe gap is +-0.03, so how do I know the gap is in the range?.

- You can measure the oil gap with a drop bar, that is, a soft drop ruler, which can be purchased without measuring the instrument of the bearing

Send your message to us

33112 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords