30328 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

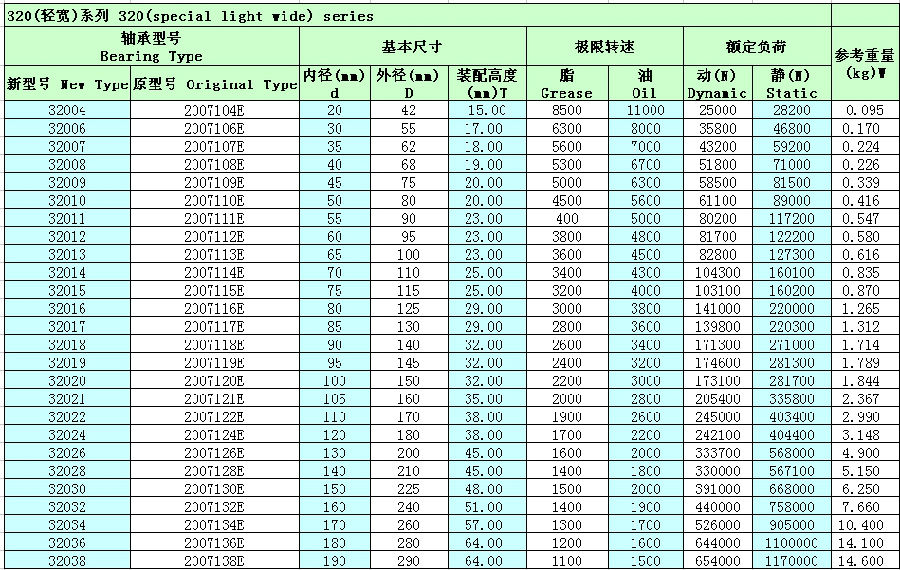

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q:What are the E and Y values of the 30209 bearings of tapered roller bearings?

- 1 、 the assembly height is 14. 2, bearing (Bearing) is an important component of modern machinery and equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement and guarantee its rotation accuracy. 3, the size of the cross section on the axis of the ladder is called the shoulder.

- Q:that is to say, the taper head is the face and the back is the back

- The installation of tapered roller bearings is not only to pay attention to the direction of installation, there are many other places to pay attention to, is a very professional technical activities

- Q:What are the general uses of tapered roller bearings?

- Micro car owners differential speedMain reducing wheel hub of light truckMain reducing wheel hub for heavy truck

- Q:The device is a vertical axis vertically arranged in the bearing chamber, the upper shaft without suspension, supported by bearings, shaft bearings are installed at the bottom of the outdoor rotating parts weighing 50 kg, the two ends of the shaft are used in single row tapered roller bearings, the bearings between the length of 30 meters. The rotation speed of the shaft is 480r/min. The device is suspended on a rotating turntable and is subjected to centrifugal force during operation...

- Why not such a large selection of axial thrust bearing, if the radial force selected contact angle greater than 45 degrees (thrust) tapered roller bearings or spherical roller bearings are good, ordinary radial cone bearing axial force mainly depends on the inner ring rib, movement and rib roller end surface contact of gyro rotation, life too effect of axial force, and excessive axial force will make rib fracture.

- Q:Tapered roller bearings 32010x, two matching, how to install?

- The design of this kind of bearings makes the inner ring raceway, outer raceway and the top of each cone face intersect the point of the central line of the roller. In addition to metric series products, there are a variety of English series products.

- Q:What does "tapered roller bearing" suffix "A" mean?

- Tapered roller bearing suffix AA - angular contact ball bearings with a contact angle of 30 degreesA5 - angular contact ball bearings with a contact angle of 25 degrees

- Q:Taper roller bearings limit speed, according to what to calculate, there is no formula for what?

- First of all, different types of tapered roller bearings, the limit speed is different. Bearing on catalog.Second, the calculation of bearing limit speed is calculated by computer simulation of bearing manufacturer. It is very complicated. Mainly based on frictional heat generation and cage strength limit.

- Q:How does the roller of tapered roller bearings fit in?

- Tapered roller bearings in the production of equipment, it is the first roller and cage assembly, and then into the inner ring, composed of components. Tapered roller bearings as long as the assembly, even if completed the inner ring, because the outer ring is only one ring.I don't know if you'll understand.

- Q:Taper roller bearings are used on my motor. Serious damage occurred during use. Please help me analyze the possible causes of damage! Thank you

- This approach is somewhat similar to a tolerance control method invented by Timken (Timken) in 80s, and is suitable for mass production. But in this way, you have to control all the variables, or you'll probably have a problem with your bearings.

- Q:There is a slot in the inner ring of tapered roller bearings, right? Is the roller in the slot?

- There is a slot in the cone... The ball is placed in the slot. Handan, north, LiAskIs there a gap between the roller and the slot?Can I move axially?Chasing the answerThere is a certain clearance between them. It is not very large. It is caused by the force...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

30328 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords