31319 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

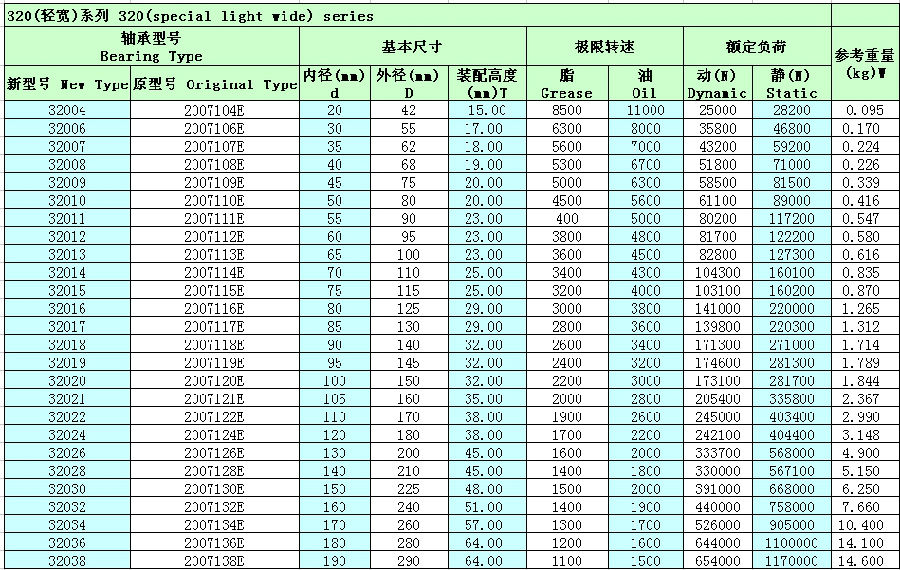

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q: Why is the cage of tapered roller bearings loose?

- You can come up with the relevant standards, must belong to the bearing standard parts, as long as you meet the standard requirements of the bearing can be spread!

- Q: What is the size of tapered roller bearings 352214?

- Bearing type: tapered roller bearingNew model: 352214Old model: 97514EInternal diameter (mm):70Outside diameter (mm):125Width (mm):75

- Q: The roller of tapered roller bearings is cylindrical or cylindrical body? Why roller drawing method of drawing section for the rectangular (here I want to add: I have seen the N version, some of the paintings is rectangular, trapezoidal and some paintings, 2 versions, a few of my book is that the proportion is A/2 the roller projection) it indicates that the real roller should be a cylinder or a cylindrical body roller is... What master?

- Cylindrical rollers are used only when the raceway is a cylinder.Mechanical drawing clearly stipulates the simplified drawing method of tapered roller bearings. Rollers are drawn into cylinders.

- Q: What are the E and Y values of the 30209 bearings of tapered roller bearings?

- 1 、 the assembly height is 14. 2, bearing (Bearing) is an important component of modern machinery and equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement and guarantee its rotation accuracy. 3, the size of the cross section on the axis of the ladder is called the shoulder.

- Q: Tapered roller bearings. Are the rollers tapered?

- As the name suggests, the roller of tapered roller bearings is conical, rather than a frustum of a cone. The roller of cylindrical roller bearings is cylindrical.

- Q: There are many kinds of tapered roller bearings, because of work requirements, test the external size is qualified, I want to make a test, to test the bearing is qualified, mainly inside and outside diameter and inside and outside the ring height tolerances, diameter ranging from 50mm--80mm, score less, look forward to your help, I thank you there are 322163311532215 main bearings, 313113002

- This is not easy yet. Do you think it's possible to make a standard check instrument yourself?!

- Q: What is the 30207 judgment coefficient e of tapered roller bearings?

- Your adoption is the driving force of my progress~~O (a O, a _) remember praise and adoption, help each other.

- Q: that is to say, the taper head is the face and the back is the back

- The bearings do not have to distinguish between the front and back, and there is no positive and negative said, only in accordance with your actual use to identify the installation direction.

- Q: Tapered roller bearing suffix code YA2 stands for what does that mean?

- I often see that bring happiness to people's lives in music is painful, hard after the success of scientists occasionally see a mirror inside the grey haired, new Chinese often over the slightest grief, I often heard people said in an interview, while working hard, but I'm happy indeed! They bear varying kuzhongzuole, showing their amazing persistence and noble quality to enjoy life without, but it is not difficult to see their happiness included "self denial".

- Q: What are the general uses of tapered roller bearings?

- At the time of greater radial load and axial load

Send your message to us

31319 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords