3003 Mill Finished Color Coated Aluminum Coils for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finished Color Coated Aluminium Coil

l Product Specification

| Coated aluminum coil | ||||

| Alloy No. | Thickness (mm) | Width (mm) | Temper | |

| A1050,A1060, A1070,A1100,A1235,A1245 | 0.2-3.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A3003,A3004,A3105 | 0.2-4.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A5052,A5083,A5754,A5005 | 0.2-4.0 | 20-1900 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-1900 | H111,H112 | ||

| A6061,A6082,A6063 | 0.8-3.0 | 20-1900 | O | |

| A8011,A1145,A1235 | 0.005-0.2 | 20-1700 | O,,H18,H24 | |

| ID | 76mm,152mm,200mm,300mm,505mm | |||

| Packing : Export wooden pallets, wooden case | ||||

| Standards:ASTM-B209. EN573-1, GB/T3880.1-2006 | ||||

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | ||||

| Application : Mainly used in signs, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | ||||

| MOQ | 2.5 tons | |||

| Payment term: | TT, L/C | |||

| Delivery Time | 15 days after 30% TT payment or receiving L/C copy | |||

| Kind attention : Specifications can be customized as the customer’s requirements. | ||||

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 15 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

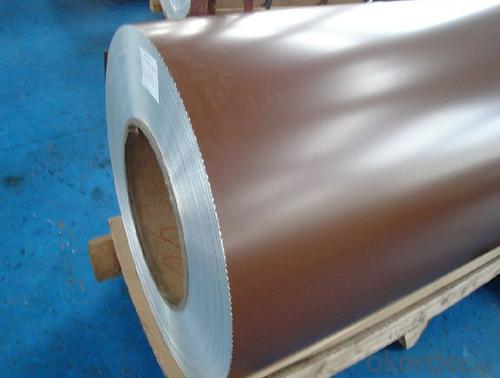

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Are there any specific regulations for the disposal of aluminum coil waste?

- Yes, there are specific regulations for the disposal of aluminum coil waste. The disposal of aluminum coil waste is subject to various environmental regulations to ensure proper handling and prevent any potential harm to the environment and human health. One of the key regulations is the Resource Conservation and Recovery Act (RCRA) in the United States. Under this act, aluminum coil waste is considered a hazardous waste if it exhibits certain characteristics such as ignitability, corrosivity, reactivity, or toxicity. If the waste meets these criteria, it must be managed as hazardous waste and disposed of in accordance with RCRA regulations. This may involve treatment, storage, and disposal at an approved hazardous waste facility. Additionally, the Environmental Protection Agency (EPA) has established guidelines for the disposal of non-hazardous aluminum coil waste. These guidelines typically require proper storage, labeling, and transportation of the waste to an authorized disposal facility. The disposal facility should be equipped to handle and process the waste in an environmentally responsible manner. In many countries, including the United States, local, state, and federal regulations may also apply to the disposal of aluminum coil waste. These regulations may vary depending on the specific location and the nature of the waste. It is crucial for businesses and individuals involved in the disposal of aluminum coil waste to familiarize themselves with the applicable regulations to ensure compliance and avoid potential penalties. Overall, it is important to follow the specific regulations for the disposal of aluminum coil waste to protect the environment, prevent pollution, and ensure the safety of individuals involved in waste management.

- Q: What are the safety measures one should take when using aluminum coils indoors?

- <p>When using aluminum coils indoors, it's crucial to ensure proper ventilation to prevent the buildup of gases that can be harmful if inhaled in large quantities. Always follow the manufacturer's guidelines for installation and operation. Keep the coils away from flammable materials and ensure they are securely fastened to prevent tipping or falling. Regularly inspect the coils for any signs of damage or wear, and replace them if necessary. Never use aluminum coils in enclosed spaces without proper exhaust systems, and always have a fire extinguisher nearby in case of emergencies.</p>

- Q: why is aluminum to the right side of the periodic table if it's a metal and why is it negatively charge if it's a mental. also if you combine it with like another metal will it be an ion since its positively charge or no because they are both metals

- It okorder /

- Q: How are aluminum coils protected against oxidation during storage?

- There are various methods used to protect aluminum coils against oxidation during storage. One commonly used approach involves applying a protective coating to the surface of the coils. This coating creates a barrier that prevents oxygen from coming into contact with the aluminum and causing oxidation. The coating may consist of a thin layer of oil or a specialized protective film. Another method involves storing the coils in a controlled environment with low humidity. This is because moisture in the air can accelerate the oxidation process. By keeping the coils in a dry environment, the risk of oxidation can be reduced. Furthermore, aluminum coils can be stored in airtight packaging, such as plastic wraps or vacuum-sealed bags. This further minimizes exposure to oxygen, thereby preventing oxidation. It is crucial to handle the coils with care during storage to avoid any damage that could potentially expose the aluminum to the air. Proper packaging and stacking techniques are essential to ensure that the coils remain protected. In conclusion, a combination of protective coatings, controlled environments, and proper handling techniques are employed to safeguard aluminum coils against oxidation during storage.

- Q: How do aluminum coils compare to brass coils in terms of corrosion resistance?

- Aluminum coils generally offer better corrosion resistance compared to brass coils. Aluminum forms a natural oxide layer on its surface, providing a protective barrier against corrosion. On the other hand, brass is a copper-zinc alloy and is more susceptible to corrosion, especially in certain environments or when exposed to moisture. However, the exact level of corrosion resistance can depend on various factors such as the specific alloy composition, coatings, and the conditions in which the coils are used.

- Q: Are aluminum coils suitable for coil coating applications?

- Yes, aluminum coils are suitable for coil coating applications. Aluminum is widely used in coil coating due to its excellent corrosion resistance, lightweight nature, and high strength-to-weight ratio. It is also highly malleable, allowing for easy shaping and forming during the coil coating process. Additionally, aluminum coils can be coated with various types of paints and coatings, providing a wide range of color and finish options. Overall, aluminum coils are a popular choice for coil coating applications due to their versatility, durability, and aesthetic appeal.

- Q: This question asks for an explanation of the various materials used for coating aluminum coils.

- <p>Aluminum coil coating materials can be categorized into several types, including: 1. Organic coatings, such as polyester, acrylic, and polyvinylidene fluoride (PVDF), which offer good weather resistance and color stability. 2. Inorganic coatings, like fluoropolymers, which provide exceptional chemical resistance and high-temperature stability. 3. Metal coatings, such as zinc or other metals, used for enhanced corrosion resistance. 4. Ceramic coatings, which are known for their high durability and resistance to heat and chemicals. 5. Laminates, which combine multiple materials for specific performance characteristics. These coatings are chosen based on the intended application of the aluminum coil, such as in construction, automotive, or packaging industries.</p>

- Q: Can aluminum coils be used in electrical busbars?

- Indeed, electrical busbars can utilize aluminum coils. Due to its high electrical conductivity, affordability, and lightweight nature, aluminum is widely employed as a busbar material. Aluminum coils can effortlessly be molded into different configurations and dimensions, tailored to meet specific busbar criteria. Furthermore, aluminum possesses commendable thermal conductivity, facilitating efficient dissipation of heat in applications involving high currents. Nevertheless, it is crucial to take into account the current carrying capacity, mechanical strength, and corrosion resistance of aluminum coils when opting for them in busbar applications.

- Q: What are the maximum and minimum coil weights available?

- The specific type of coil being referred to can cause variations in the available maximum and minimum coil weights. When considering electrical coils, such as those utilized in transformers or motors, factors like wire size, material, number of turns, and intended application determine the maximum and minimum coil weights. Manufacturers generally set weight limits on these coils, which can range from small and lightweight to large and heavy. For instance, a small coil may have a maximum weight of a few grams, while a larger coil could weigh several kilograms. To ascertain the maximum and minimum coil weights for a specific application, it is essential to consult the manufacturer or supplier's specifications.

- Q: I know this question is not so bright, but I am very curious why do we recycle aluminum cans? Is it that they are not biodegradable?

- Save the Rainforest! Recycle Aluminum! Did you know that aluminum comes from the ore Bauxite? And that bauxite is mined in the rainforest? Every time you throw away an aluminum can, that's one less that is being recycled, and one more can's worth of bauxite that needs to be mined from the rainforest. The bad thing about mining bauxite, just like any other ore, is that it is in the ground. Since bauxite is mined in the rainforest, there are tons of trees growing on top. In order to get to the bauxite, the trees have to be clear-cut and are usually burned since there main opperation is to mine the ore, not harvest lumber. This puts a lot of pollution into the air from the trees burning and the fossil fuels spent for the machinery to take them down. Once the land is clear, mining begins, burning even more fossil fuels. Then the ore is shipped to a facility that turns the ore into aluminum (another energy-expensive process) and then the aluminum is finally shiped to us (again, more energy, i.e. fossil fuels spent) so that we can then, finally, make cans out of them. So why don't we just make new cans out of the old ones when we are done with them? They are already here, no need for shipping. They are free, just need to be trasported to the recycling facility. And we don't have to cut rainforests to get more aluminum if we use what we've already got. Some day we will be mining our landfills because we've irresponsibly and selfishly used up our resources elsewhere. Hope this answers your question and gives you the motivation to start recycling!

Send your message to us

3003 Mill Finished Color Coated Aluminum Coils for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords