20t heavy duty Explosion-Proof chain block

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBM

Model Number: HBSQ20T

Usage: Construction Hoist

Power Source: Hand Chain

Sling Type: Chain

Maximum Lifting Weight: 20tons

Maximum Lifting Height: 3M

Lift Speed: same with pulling speed

Certification: CE,GS and ISO9001

Warranty: one year

After-sales Service Provided: No overseas service provided

Capacity: 20 tons

Standard lift height: 3M

Running test load: 20TONS

No.of falls of load chain: 8

Net weigth: 180kg

Color: cooper hoist

Description: Explosion-Proof chain hoist

Main Features

Superior rigidity makes the hoist dust-proof and water-pfoof;

Severe environment and work condition are acceptable;

Simple structure and few components

Adopt Janpanese FEC chain;

To greatly enhance the performance of the fatigue and wearresistance.

Limit protection adevice can avoid overload occerring;

Hook bolt can prevent the rigging accidently from slip;

Moter is equipped with thermal protection device;

limit contactors are set in the machine.

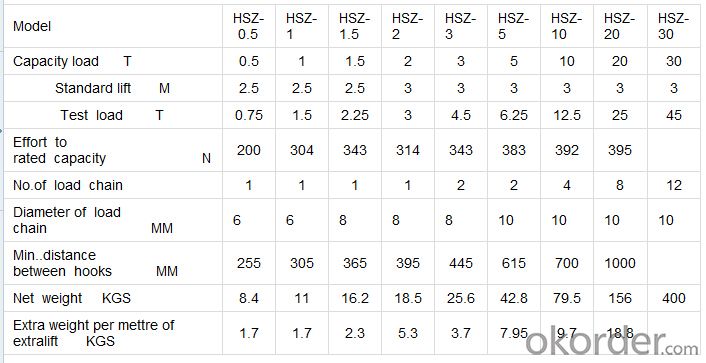

Parameter List

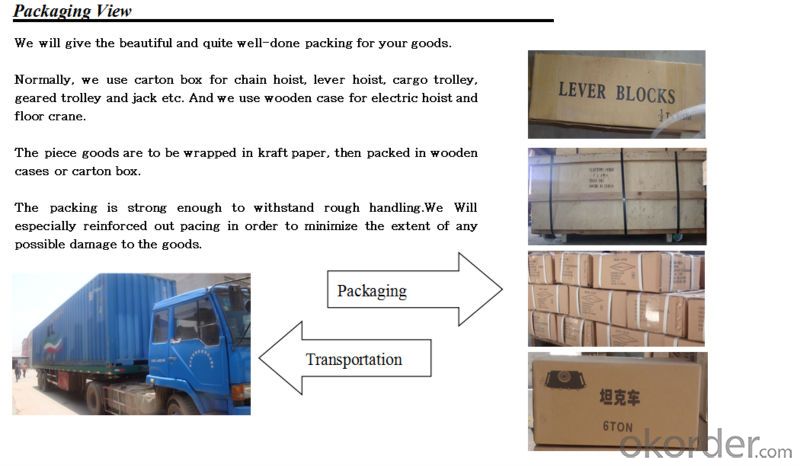

Our Service

1.We can make special sample according to the customer’s requirement.

2. We have more than 60 professional technical team, provide best after-sales service.

3. Fast delivery time.

4. We have CE, ISO9001 and GS certification.

FAQ

1.What’s your product range?

Electric Hoist: electric chain hoist , electric wire rope hoist, mini wire rope electric hoist, mini electric chain hoist.

Manual Chain Hoist and Lever Hoist Chain , Trolley , Jack,Lifting Strap,Cable Pulley, hand pallet truck,etc.

2.When Can I get the quotation?

We usually quote within 24 hours after we get your inquiry . If you are very urgent to get the price , please tell us in your email so that we will regard your inquiry priority.

3.How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you need the samples, you need pay the express fee ,

4.What information should I let you know if I want to get a quotation?

1. Lifting capacity.

2. Lifting height.(hook center to ground)

3. Power supply: Voltage.

4. Span(rail center to rail center)

5. Working condition: which material to lift? temprature?

6. Would be better if you have drawings of your plant.

- Q: What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- A set of wire rope sling series: adhesive wire rope sling, wire rope sling, inserted Aluminum Alloy pressed wire rope sling, no joint wire rope hanger, wire rope sling, multifurcating nylon cord steel wire rope, plastic rope.

- Q: Where should I pay attention to the formwork?

- When the welded steel bar and the formwork are installed together, the following requirements shall be met:The formwork must be fixed on the joint of the load-bearing welded steel frame;When installing the reinforcing steel formwork assembly, the sling shall be tied up according to the hanging point designed by the template.

- Q: Is rope sling good business and high profit?

- The atmospheric environment should be optimized by the manganese phosphating coating steel wire rope, and the heavy corrosion environment should be preferably galvanized - phosphating double coated steel wire rope.

- Q: Why do not different kinds or different sizes of slings and slings are used together?

- Choose proper slings and slings according to the specific conditions of the heavy loads; no heavy weights are allowed to be attached directly with the hooks, and no different kinds are allowed

- Q: What does the inspection of rigging involve?

- Phosphating coating of steel wire rope (Chinese patent), wire by Mn and Zn Mn phosphating treatment of steel wire, wear resistance and corrosion resistance of fully, are not easy to wear and corrosion fatigue life of the phosphating coating steel wire rope is the same structure of plain steel wire rope 3 times (laboratory comparable conditions), exceeding imports of steel wire rope, phosphating coating steel wire rope are fully replace all kinds of plain steel wire rope, also be replaced after plating the first pull layer thin zinc galvanized steel wire rope used (through salt spray test the corrosion resistance test), long service life, use lower cost, better quality stability and reliability.

- Q: Ceiling installation does not allow the use of air nails?

- (1) construction materials: common materials are as follows.Wood (different specifications of water, wood, water board), aluminum alloy (plate, profile), steel (steel, flat steel, steel plate), mainly as supporting components.Plastic, plexiglass plate, glass partition plate, outer decorative veneer and heat dissipating plate, copper plate and electrochemical aluminium plate as decorative component.Other accessories such as screws, nails, rivets, finished lamps, adhesives and so on.(2) construction tools: pliers, screwdrivers, hammers, saws, electric hammer, hand according to the curve, a ruler, paint etc..

- Q: How do you tie the wire rope?

- The price of phosphating coating wire rope is higher than that of smooth steel wire rope, but the unit use cost is lower than the smooth steel wire rope. The test data indicate that fatigue life of phosphating coating steel wire rope is 3-4 times of plain steel wire rope, wire rope life and fatigue life is proportional to, according to the current market price of roughly wire rope, manganese phosphating coating of steel wire rope although the price is higher than that of plain steel wire rope, and prolonging the service life of much higher than the rate of price increase so, the phosphating coating steel wire rope, the average daily cost of using only smooth steel wire rope 30-45%, longer service life, lower cost per use, stability and security in the process of using and more cost-effective products, light surface wire rope upgrade, for reference only

- Q: What are the installation steps for crane beams?

- The crane beam and track shall be corrected after the main component is fixed. Fix immediately after correction, in order of fixation, bolt first and then weld.

- Q: Slings and rigging manufacturers, which cost-effective?

- Phosphating coating of steel wire rope than plain steel wire rope has long service life, lower cost, better stability, phosphating coating of steel wire rope is patent technology production, because the demand is more difficult to buy, to ask the producer of several wire rope, please note in the purchase, purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope to prevent illegal enterprises, infringement of their legitimate rights and interests, in addition, patent products are generally in the rope on the outer packing of a patent spraying label, warranty should be the main technical indicators, such as the phosphating film type and film weight

- Q: How to choose the right sling?

- The selection of rigging should be adapted to the kind of articles, environmental conditions and specific requirements.The sling to carry out strict inspection, in accordance with safety color to use, if found damaged sling can not be reused, need for scrap processing.The slings used for lifting operations must be of the same length.The sling shall not exceed its rated lifting capacity, and the sling shall not exceed its maximum safe working load.

Send your message to us

20t heavy duty Explosion-Proof chain block

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords