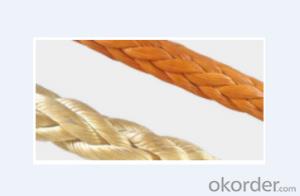

High Strength Mooring Rope,polyester, High Molecular Polythylene (UHMWPE).

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 0 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mooring Rope

Production Scope: The structure of mooring rope can be divided into 3-strand, 6-strand, 8-strand and 12-strand. The raw material includes: polypropylene, polyester, nylon, High Molecular Polythylene (UHMWPE), aramid fibre and synthetic fibre. Diameter scope: Φ6mm ~ Φ140mm are available.

Characteristics of mooring rope: high tensile, low stretch, anti-friction, corrosion resistance, soft and smooth, easyto operate, etc. Mooring ropes are mainly used in shipping equipment, fishing industry, port operation, electric construction, oil exploration, national defense and sports goods, etc.

Achievements in scientific research:

In 1997, we drafted out the industrial standard for textile slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic progress for the Chinese textile sling industry.

In 2007, we revised JB/T8521.1-2007 “Textile Sling – Safety - Part 1: Common use webbing sling” and JB/T 8521.2-2007 “Textile Sling - Safety - Part 2: Common use round sling”.

In 2009, we edited GB/T 23914.2-2009 “Road vehicle mounted fixtures – Safety – part 2: Synthetic ratchet strap assemblies”, participated in writing TB/T 3123.11-2009 “Rescue devices for railway accidents - part 11: high-performance textile sling”.

In 2014, we participated in writing GB/T 30667-2014 “Polyester and polyolefin dual Fiber rope” and GB/T 30668-2014 “8 strands, 12 strands and multiflament braided Ultra high molecular weight polyethylene fiber rope”.

- Q: What tools are slings in lifting operations? What is the function of the slings?

- Sling made forms are more commonly used in engineering with inserting end ring and inserted nonpolar (Universal) slings in hoisting work are the steel wire rope is connected with a hook, shackle, sling made of various styles, for lifting, or binding.

- Q: What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- A set of wire rope sling series: adhesive wire rope sling, wire rope sling, inserted Aluminum Alloy pressed wire rope sling, no joint wire rope hanger, wire rope sling, multifurcating nylon cord steel wire rope, plastic rope.

- Q: Do cranes have the same wire ropes, slings, slings and cables?

- To be exact, different things are very relevantThe cable belongs to the sling and belongs to the spreaderA wire rope can be made into a wire rope rigging

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility of. According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: What's the sling for a movie?

- Now the movie also used the wire, but the rope is made by thin steel wire, so as not to betray. WIA, commonly known as wire.

- Q: What are the precautions for rigging in hoisting works?

- 1. develop good hoisting habits and plan how to hang, lift and unload before lifting.2. prepare: determine the weight of the hanging object and its center of gravity, read the attached document carefully, mark the lifting point and weight data. Only when the center of gravity has been determined can the hook be hung at the right place!3. the crane operator shall be informed of the weight of the suspended object.4. the crane hook shall be hung vertically above the center of gravity of the suspended object.5. lifting heavy pieces, both to avoid damage to lifting objects, but also to prevent damage to the rigging itself. The following conditions shall be observed in order to avoid rotation or fall:(a) single leg rigging, the lifting point shall be perpendicular to the center of gravity of the lifting object.(b) if it is a two leg rigging, the suspension point shall be on either side of the lifting object, with the lifting point above the center of gravity.(c) if it is a three leg and four leg rigging, the suspension point shall be evenly located at the center of gravity of the lifting object, and above the center of gravity of the suspended object.Attention must be paid to the lifting angle, between the vertical and the leg): the greater the lifting angle, the smaller the lifting capacity. Lifting angles of more than 60 degrees are absolutely not allowed!

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 4. coated steel wire rope, the carbon steel wire rope based on the rope or rope coated with polyethylene or polypropylene5. smooth wire rope, in 1834 the British began production in China in 1939 started production in Tianjin No.1 steel wire rope factory, with the phosphating coating steel wire rope into the market size gradually increased, will be fully replace phosphating coating steel wire rope.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- Cable-stayed bridge, also called cable-stayed bridge, is a bridge that uses many cables to directly pull the bridge on the pylon. It is a structural system composed of a pressure tower, a tensile cable and a bent beam. It can be regarded as a multi span elastically supported continuous beam instead of a pier. The utility model can reduce the bending moment in the beam body, reduce the height of the building, lighten the weight of the structure and save the material.The cable-stayed bridge is composed of pylon, main girder and stay cable.

- Q: Which sling manufacturer is more reliable?

- Rigging is made of wire rope, plug or aluminium alloy head, and the key to the service life of the rigging is the quality of the wire rope.

- Q: Notice of tower crane?

- The metal structure of the tower crane, the track and the metal shell of all the electrical equipment shall have reliable earthing devices, and the grounding resistance shall not be greater than 4 ohms, and lightning protection devices shall be set up.Fourth. Pole arrangement, each attachment device attached to the wall and spaced distance should be in accordance with the provisions of the original factory, homemade bar design calculations should be.

Send your message to us

High Strength Mooring Rope,polyester, High Molecular Polythylene (UHMWPE).

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 0 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches