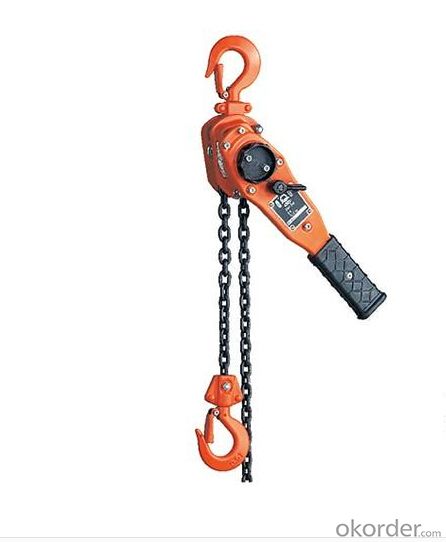

10t heavy duty Explosion-Proof Chain block

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBM

Model Number: HBSQ10T

Usage: Construction Hoist

Power Source: Hand Chain

Sling Type: Chain

Maximum Lifting Weight: 10tons

Maximum Lifting Height: 3M

Lift Speed: same with pulling speed

Certification: CE,GS and ISO9001

Warranty: one year

After-sales Service Provided: No overseas service provided

Capacity: 10 tons

Standard lift height: 3M

Running test load: 10TONS

No.of falls of load chain: 4

Net weigth: 83kg

Color: cooper color

Description: cooper chain hoist

Main Features

Superior rigidity makes the hoist dust-proof and water-pfoof;

Severe environment and work condition are acceptable;

Simple structure and few components

Adopt Janpanese FEC chain;

To greatly enhance the performance of the fatigue and wearresistance.

Limit protection adevice can avoid overload occerring;

Hook bolt can prevent the rigging accidently from slip;

Moter is equipped with thermal protection device;

limit contactors are set in the machine.

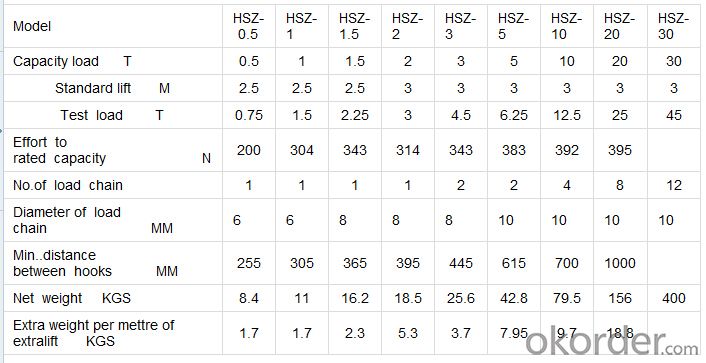

Parameter List

Our Service

1.We can make special sample according to the customer’s requirement.

2. We have more than 60 professional technical team, provide best after-sales service.

3. Fast delivery time.

4. We have CE, ISO9001 and GS certification.

FAQ

1.What’s your product range?

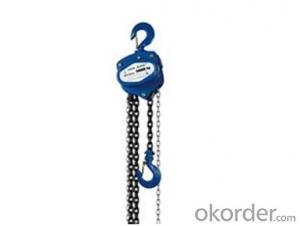

Electric Hoist: electric chain hoist , electric wire rope hoist, mini wire rope electric hoist, mini electric chain hoist.

Manual Chain Hoist and Lever Hoist Chain , Trolley , Jack,Lifting Strap,Cable Pulley, hand pallet truck,etc.

2.When Can I get the quotation?

We usually quote within 24 hours after we get your inquiry . If you are very urgent to get the price , please tell us in your email so that we will regard your inquiry priority.

3.How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you need the samples, you need pay the express fee ,

4.What information should I let you know if I want to get a quotation?

- Q: What is the difference between cable stayed bridge and suspension bridge?

- Cable stayed bridge is one of the most popular types of long-span bridges in china. So far, there are more than 3O cable-stayed bridges completed or under construction, second only to Germany and Japan, and the third place in the world. And the number of long-span concrete cable-stayed bridges has been ranked first in the world.In the middle of 50s, the first modern cable-stayed bridge was built in Sweden. For more than 40 years, the development of cable-stayed bridge has a strong momentum. In the middle of 70s, China began to build concrete cable-stayed bridges. After the reform and opening up, the momentum of the construction of cable-stayed bridges in China has been on the rise.China has been developing the concrete cable-stayed bridge mainly. In recent years, China has begun to build a hybrid cable-stayed bridge with steel and concrete, such as the Shantou stone bridge, the main span 518m, and the Yangtze River Third Bridge in Wuhan, the main span 618m. Steel box cable-stayed bridges, such as Nanjing Changjiang second bridge, South Branch bridge, main span 628m, Wuhan military mountain Yangtze River bridge, main span 460m. A few years ago, the Nanpu (main span 423m) and Yangpu (main span 6O2m) bridge built in Shanghai were steel and concrete composite beam cable-stayed bridges.

- Q: What is the line on the train for?

- The contact wire is mostly made of steel aluminum core, that is, the outside is made of steel, and the main part is the friction part of the pantograph. To ensure the conductivity and wear resistance, the aluminum core is mainly to ensure the conductivity. Copper and aluminum composite wires have also been used as contact wires.

- Q: What are the dangerous sections of the crane hook?

- ) C -C section of the section is the thinnest part of the hook column in a sling tension, have pulled off the trend. Here the maximum tensile stress, it is also dangerous section.

- Q: What is the name of the wire above the train?

- It's called catenary. There are two lines up and down. The upper part is called the load line, and the lower one is called the contact line. There is a sling connection between the cord and the contact wire.

- Q: Why do not different kinds or different sizes of slings and slings are used together?

- Or different specifications of slings and slings are used together; the carrying capacity of the sling shall not exceed the rated lifting capacity; the sling shall not exceed the safety load; the lifting crane shall check whether the connection point is firm and reliable

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility of. According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: What does the inspection of rigging involve?

- The crane used in atmospheric environment, preferably manganese phosphide coating, steel wire rope, heavy corrosive environment, preferred hot-dip galvanized double phosphating steel wire rope, priority wire rope in sea water. Please note that at the time of purchase, in the purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope or 316 stainless steel wire rope, prevent illegal infringement of their legitimate rights and interests of enterprises, to counterfeit products in addition, patent products are generally in the rope on the outer packing is patent spraying mark, warranty book should be the main technical indicators, such as the phosphating film type and weight (film has an important influence on the weight of phosphating film size, wear resistance and corrosion resistance of the service life of the wire rope, for reference only)

- Q: Ceiling installation does not allow the use of air nails?

- Installation notes: installation should pay attention to the following three points.When installing, if there are many chandeliers, we should pay attention to their location, length and length, and install the ceiling lamp while installing the ceiling, so that the position and height of the lamp can be adjusted on the basis of the ceiling and joist.The hanger on the ceiling must be made by direct out method and by adding bushing. The method of adding sleeves is good for installation, and it can ensure the integrity of the ceiling panel. The boom that is directly out of the ceiling can not be easily drilled when installing, and sometimes the method of installing the suspender first and cutting the hole of the panel is adopted, but the decorative effect is affected.The boom should have a certain length of thread for adjusting height. Attention should be paid to the reliability of the hanging light box under the suspender and suspender.

- Q: The wire rope lock can hang a lot of things

- Phosphating coating of steel wire rope (Chinese patent), steel wire by manganese or zinc manganese phosphating, surface wear resistance and corrosion resistance of fully, not easy to wear is not easy to corrosion fatigue life of the steel wire rope large increase, fatigue life is the same structure of plain steel wire rope 3 times, the fatigue life can be verified by fatigue test (do the fatigue test of the most credibility) is a replacement of wire rope, smooth upgrade, also be replaced after plating the first pull layer of thin zinc galvanized steel wire rope (by using salt spray test or inspection service life, corrosion resistance comparison) super long units, the use of lower cost, better stability.

- Q: What are the installation steps for crane beams?

- Crane operation is relatively dangerous, the installation of crane beam should be standardized to ensure the safety of crane operation. How many points should I pay attention to when installing the crane?:(1) the actual elevation of the corbel should be measured before the installation of the steel crane beam, so that the construction error of the elevation can be adjusted when the crane beam is installed, so as to prevent the error accumulation.The installation sequence of crane beam is as follows: installing crane beam, installing auxiliary truss and installing brake beam.(2) crane shall be used by slings, lashing or reliable clamps. The binding point shall be determined according to the weight and length of the crane beam. Generally, the angle of the sling shall be greater than 45 degrees at the ends of the center of gravity of the crane beam.(3) should be placed after the crane beam, the connecting plate is connected with the fixed edge plate and column crane girder structure, to prevent the crane hook loose after crane girder longitudinal and lateral movement of dumping.(4) crane beam correction should be performed in all bolts after installation, to prevent the installation of bolts when the crane beam shift change; prohibited welding in the crane girder under the flange and web on suspension and fixture.(5) adjust the elevation of the crane beam, correct the center line and span after titanium.

Send your message to us

10t heavy duty Explosion-Proof Chain block

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords