Lifting Belt Assembly Master Link Hooks End Fitting Shackles Round Slings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

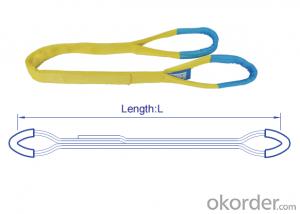

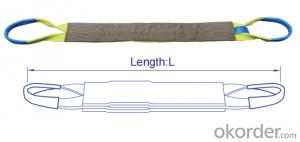

LIFTING BELT ASSEMBLY

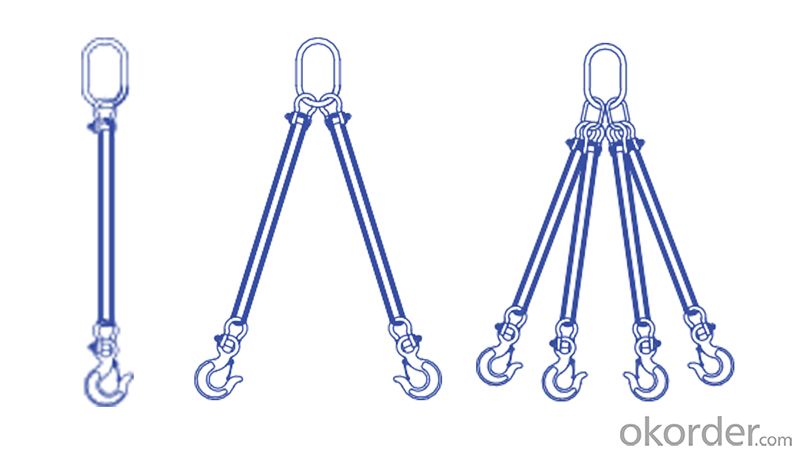

Lifting belt assembly mainly consists of master link,shackles,lifting belts,hooks and end fittings.Based on different customer demand,we can assemble into single-leg,double- leg,three legs,four legs and so on.The metal accessories can be chosen flexible according to the practical use needs,it makes convenient and safety to operate.

Note:The end fitting includes the shackle,clamp or hooks.

Ø We have master link,round link and assembly link available for main link.

Ø Connecting link including bow shackle,connecting link. Textile sling including webbing sling and round sling. End fitting including hook and others.

Ø The sling set can be assembled according to customer’s requirement.

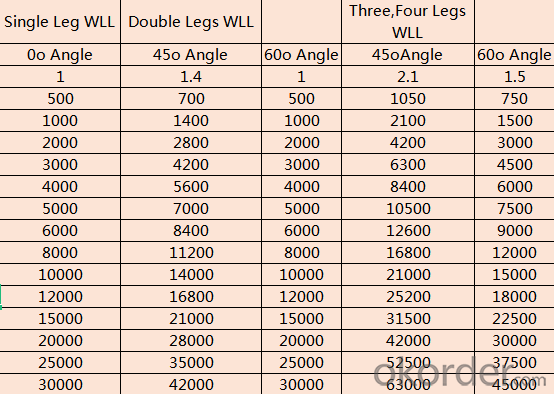

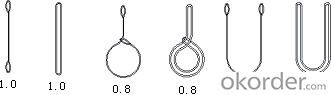

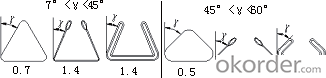

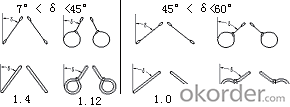

Ø Please notice the relation with angle and tonnage during usage.

Ø Safety factor 4:1,higher safety is available upon request. The graphic shows the Working Load Limit, not for standard size sling.

Main usages and applications

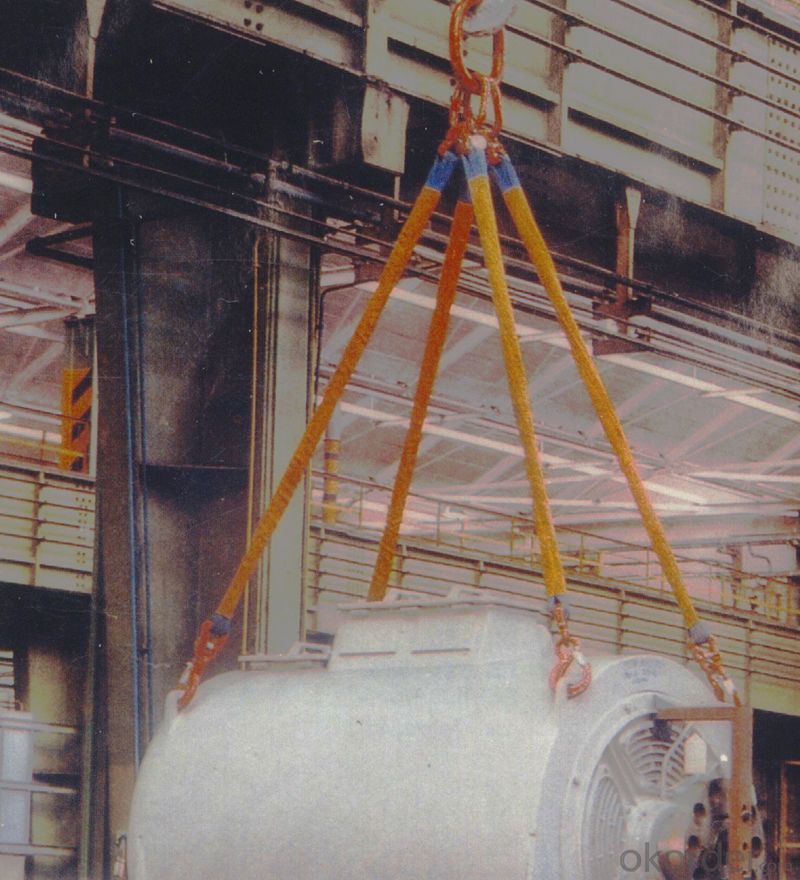

It is used to enhance the connection between the tool and hanging objects, mainly used in machinery processing, port handling, shipbuilding, electrical installation, transportation, aerospace and other hoisting field.

Product working conditions

Sling usage temperature : - 40 C ~+100 C, when using polypropylene sling

- 40 ~+80 respectively, used in high temperature environment is strictly prohibited.

Avoid molten metal, glass, fragile items, nuclear reactor, as well as other adverse environments used in the sling lifting operations.

Product working conditions

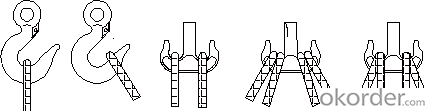

Put the sling directly into the center position of the hook, cannot be directly

hung on hooks’ tip, as shown in figure 1.

When Two slings are used, put them directly into the double hook , Put the

slings directly into the center position of the hook, as shown in figure 1.

When Four lifting Slings are used, put every two of the slings directly into the double hook ,the two sling cannot overlap, four slings to be symmetrical to the center of the hook, as shown in figure 1.

When use Two or four sling, when no special requirements on the length error , its nominal length deviation should be allowed no more than sling standards. Multiple leg lifting sling angle and calculation factor of limit load, as shown in figure 2 and table 1.

The sling can be operated as shown in Diagram 3.

Before using the Sling, there must be a trail lifting, the hanging point and the gravity of the lifted item must be in the same plumb line.

The sling,loops and metal accessories must guarantee the curvature radius,avoid the load absorption of the sling crippled due to the shear force. During using the sling, prohibit using knot to connect the slings, should use special connecting parts to connect.

Precautions for use

Sling working load limit based on the identification of the sling, overloading

use is strictly prohibited.

Cross or twist using is not allowed, knotted, twisted is not allowed.

In the process of lifting, lifting items is strictly prohibited by the collision and impact.

Check the lifting sling connectors if they are connected properly. Lifting process should try to remain stable,nobody is allowed to stand or pass through below the hanging item.

When hoisting up may not let the body of sling touch any other item, So as not to damage it.

Maintenance and Repair

Avoiding heat sources ( fire and electrical welding ) or sunlight and UV radiation under the conditions of long storage.

After being used, the sling should be placed on store shelves after use, should not be placed directly on the ground, to avoid going moldy and mouse biting. When being used under acid and alkaline conditions, immediately rinse with cold water or cleaning agent,dry storage.

Make sure the sling stored after drying,to avoid dampness and mildew.

Discard as useless

When the product appears one of the following conditions,it should be scrapped.

If the body, eye is seriously cut or scratched,1/10 of the width or 1/5 of the thickness is confirmed, Fluff up so as to the banding pattern is invisible, you can confirm that the warp injury.

Erected fluff makes the texture invisible that can be identified as warp damage.

Sewing thread breaks, cannot keep the shape of the eyes, or detachments.

Synthetic Fiber softening or deterioration, spalling, surface roughness, synthetic elastic smaller,and less intensity.

Sling moldy, acid and alkali Burns, hot - melt or burn, loose surface, and corrosion.

Hardware appears distorted, deformed, edge damage, notch injury, cracks, corrosion wear more than 10% of original size.

Period of usage, based on the usage of the sling to determine ; even if there is no apparent damage and abnormalities, if the use of the term is exceeded, the indoor use for more than 7 years ; outdoor use for more than 3 years..

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:1.210 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

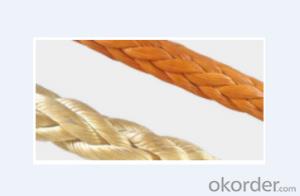

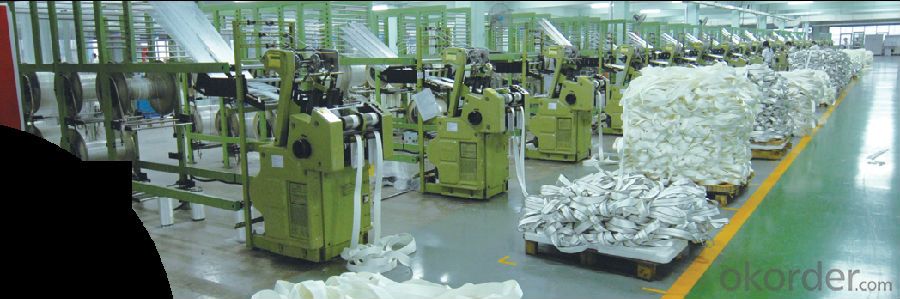

Textile sling factory is the largest base for lifting belts in the world with the production capacity "over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines "from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc. The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope "and traction rope, according to different using environments, different materials would be used, "such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene "material).

We are able to manufacture special slings such as high-strength type, flame retardant "type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant "type, fluorescent type, optical inspection type and oil and water resistant type sling. With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other "operations in machining, port handling, marine engineering, ship, electric power, transportation, "aerospace and other fields. Achievements in scientific research:In 1997, we drafted out the industrial standard for textile "slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic "progress for the Chinese textile sling industry. "In 2007, we revised JB/T8521.1-2007"Textile Sling – Safety - Part 1: Common use webbing "sling" and JB/T 8521.2-2007"Textile Sling - Safety - Part 2: Common use round sling". In 2009, we edited GB/T 23914.2-2009"Road vehicle mounted fixtures – Safety – part 2: "Synthetic ratchet strap assemblies", participated in writing TB/T 3123.11-2009"Rescue devices for "railway accidents - part 11: high-performance textile sling". In 2014, we participated in writing GB/T 30667-2014"Polyester and polyolefin dual Fiber rope "and GB/T 30668-2014"8 strands, 12 strands and multiflament braided Ultra high molecular weight "polyethylene fiber rope".

- Q:What's the sling for a movie?

- WIA, is used to protect the athlete's device is generally with a strong rope tied to the athlete's protection belt.

- Q:What's the catch?

- Slings are ropes made of wire or synthetic fiber, used for hoisting.

- Q:What does the inspection of rigging involve?

- The crane used in atmospheric environment, preferably manganese phosphide coating, steel wire rope, heavy corrosive environment, preferred hot-dip galvanized double phosphating steel wire rope, priority wire rope in sea water. Please note that at the time of purchase, in the purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope or 316 stainless steel wire rope, prevent illegal infringement of their legitimate rights and interests of enterprises, to counterfeit products in addition, patent products are generally in the rope on the outer packing is patent spraying mark, warranty book should be the main technical indicators, such as the phosphating film type and weight (film has an important influence on the weight of phosphating film size, wear resistance and corrosion resistance of the service life of the wire rope, for reference only)

- Q:What is the line on the train for?

- The catenary provides 25 thousand volt power frequency alternating current for the locomotive, according to the locomotive model difference, adopts the direct step-down, the frequency conversion power supply or the AC and DC conversion power supply, this is mainly for the speed regulation convenience.

- Q:Which sling manufacturer is more reliable?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q:What is the name of the wire above the train?

- The contact wire is mostly made of steel aluminum core, that is, the outside is made of steel, and the main part is the friction part of the pantograph. To ensure the conductivity and wear resistance, the aluminum core is mainly to ensure the conductivity. Copper and aluminum composite wires have also been used as contact wires.

- Q:Ceiling installation does not allow the use of air nails?

- Connection of hanging cup, sling and structural layerOperation method: (1) the main consideration connected with embedded parts and transition piece.In the first layer in embedded iron or wood brick (except water brick). The location shall be accurate and adequate adjustment should be made.The transition in the iron and wooden fittings, so as to adjust the mindware error, and mindware nail, screw, welding, wear.The suspender and the sling are connected with the transition connecting piece.

- Q:How much is the crane arm of the tower from the residential building recently?

- (1) hook safety device: a sling that prevents the hook from slipping and is automatically slipped from the hook. A spring is arranged at the opening of the hook head to seal the opening; the spring sheet can only be pressed downwards and can not be turned upwards after being put into the sling to prevent the sling from falling off automatically.(2): reel insurance device is effective measure to prevent accidents caused by improper wire rope winding drum out outside. There are different ways to do this. The main reason is that a steel bar is welded outside the drum to restrict the wire rope to move within the reel range.(3) fixed foundation: the depth of digging pit is 600mm, the concrete is poured on the lime soil, the surface is smooth, and the waterproof and earthing protection measures are adopted.

- Q:Requirements and matters needing attention in hoisting

- We often encounter equipment installation, transport and installation work, whether the derrick is lifting or hoisting machinery should pay attention to the following points: (1) the indigenous construction equipment for handling mobile rolling method, the rolling rod thickness should be consistent, should buetow annual row width is 50cm long, no gloves in rollers. While loading and unloading piping shall not be greater than 20 degrees slope, raceway erection should be smooth, solid, joints staggered, the rolling speed is not too fast, when necessary to use ropes.(2) in the course of installation, if problems are found, measures should be taken in time, and then continue to be hoisted after treatment.(3) large tower equipment for hoisting derrick, hoists joint operation, the hoist hoisting speed must be roughly the same, to ensure that the tower body of each suspension force roughly uniform, avoid the tower stress uneven deformation.

- Q:What is the influence of lifting angle on rigging?

- The vertical lifting is the best scheme for lifting. The smaller the angle between the sling and the vertical is, the greater the angle is, the greater the force the sling will bear. The sling will be easily broken off, which will lead to an accident, which is for reference only

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lifting Belt Assembly Master Link Hooks End Fitting Shackles Round Slings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords