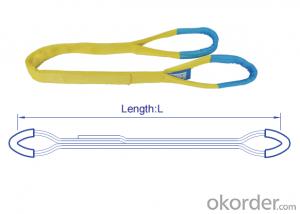

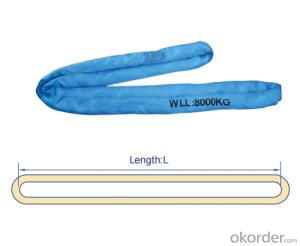

High Tensile Endless Eye Type Round Slings Customers Requiement Webbing Sling Type rh02

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Tensile Endless Type Round Slings Customers Requiement

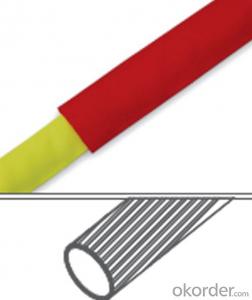

It is made of Ultra High Molecular Weight Polyethylene fiber, the tensile of which is 3-4 times of polyester fiber. It is High modulus and low elongation type fiber and the proportion is 0.97g/cm³(lighter than water).

The performance of the fiber such as UV-resistant, shock - resistant, acid - resistant, corrosion - resistant, wear – resistant, etc. are all much better than other synthetic fibers.

Advantages: Small size, light weight, soft, safe, low elongation, UV-resistant, wear – resistant, shock - resistant, corrosion – resistant, non-conductive, anti- static, long servicae life.

Low-temperature performance is good, operating temperature range: -125 ℃ ~80 ℃ , the weight is 1/4 of common round sling and the diameter is 1/2 of

common round sling.

Certification: GS, CE, ISO

Customized support: OEM, ODM

Place of Origin: Hebei, China

Brand Name: j&L

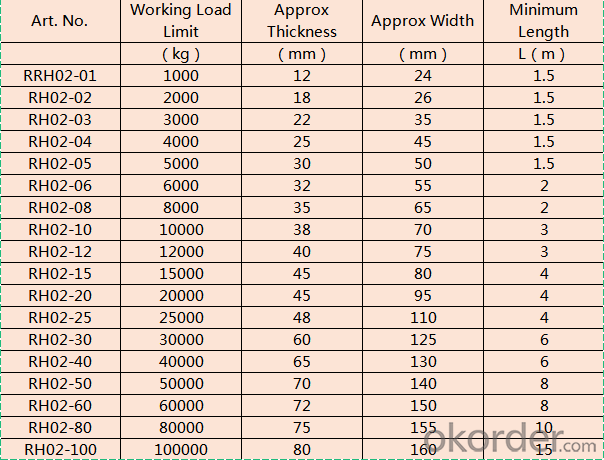

Model Number: R02

Type: Round Sling

Shape: Round

Sling Color: Green

Lifting Eye Type: Flat Eye

Color: Customers Require

Product name: Polyester Round Sling

Application: Lifting Goods

Safety factor: 5:1 6:1 7:1 8:1

Length: Customized Length

Width: Customized Width

Standard: CE/GS/ISO9001

Packing: Customers Requiement

MOQ: 1 Piece

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:1.210 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

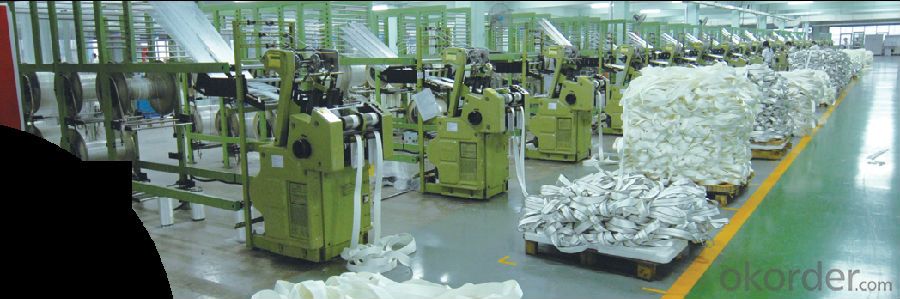

Textile sling factory is the largest base for lifting belts in the world with the production capacity "over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines "from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc. The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope "and traction rope, according to different using environments, different materials would be used, "such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene "material).

We are able to manufacture special slings such as high-strength type, flame retardant "type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant "type, fluorescent type, optical inspection type and oil and water resistant type sling. With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other "operations in machining, port handling, marine engineering, ship, electric power, transportation, "aerospace and other fields. Achievements in scientific research:In 1997, we drafted out the industrial standard for textile "slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic "progress for the Chinese textile sling industry. "In 2007, we revised JB/T8521.1-2007"Textile Sling – Safety - Part 1: Common use webbing "sling" and JB/T 8521.2-2007"Textile Sling - Safety - Part 2: Common use round sling". In 2009, we edited GB/T 23914.2-2009"Road vehicle mounted fixtures – Safety – part 2: "Synthetic ratchet strap assemblies", participated in writing TB/T 3123.11-2009"Rescue devices for "railway accidents - part 11: high-performance textile sling". In 2014, we participated in writing GB/T 30667-2014"Polyester and polyolefin dual Fiber rope "and GB/T 30668-2014"8 strands, 12 strands and multiflament braided Ultra high molecular weight "polyethylene fiber rope".

- Q: What is the influence of lifting angle on rigging?

- Slings are usually steel wire ropes or chain slings. Wire ropes have manganese phosphating coating, steel wire rope, galvanized steel wire rope, manganese phosphating coating, steel wire rope is new technology product, and fatigue life is three times of smooth steel wire rope.

- Q: Is rope sling good business and high profit?

- With an annual output of 1 million 800 thousand tons of steel China ranked first in the world, is the first world phosphating wire rope wire rope surface treatment inhibited fretting fatigue to prolong the useful life (fatigue life), business wire rope and rigging, ordinary product profit, if can be linked to the manganese phosphating coating of steel wire rope, the profit is very high

- Q: How much is the crane arm of the tower from the residential building recently?

- (1) the drivers and signaling personnel of the tower cranes must be specially trained and issued certificates by the relevant departments, and attention should be paid to whether the type of tower used by the driver is consistent with the actual tower type.(2) special person special plane management, Captain responsibility system, and strict shift shift system.(3) the newly installed or repaired tower crane must perform the machine test operation according to the specifications.(4) tower crane should keep a safe distance from overhead transmission lines.(5) driver's room should be equipped with fire extinguishing equipment.

- Q: How do you tie the wire rope?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q: The wire rope lock can hang a lot of things

- 2. galvanized steel wire rope, including hot-dip galvanizing and electro galvanized two, in general, hot galvanized zinc layer thickness, zinc plated zinc thin3. stainless steel wire rope, 304 or 316 stainless steel based, anti-corrosion effect is very good, but expensive4. carbon coated steel wire rope, wire rope based on polyethylene, polypropylene or nylon outer coating5. smooth wire rope, short service life, sharp decline in market demand, will be phasing out the phosphating coating steel wire rope.

- Q: What are the selection principles for lifting cranes?

- It can guarantee the quality of hoisting project, safety construction and certain economic benefits.

- Q: What are the installation steps for crane beams?

- Crane operation is relatively dangerous, the installation of crane beam should be standardized to ensure the safety of crane operation. How many points should I pay attention to when installing the crane?:(1) the actual elevation of the corbel should be measured before the installation of the steel crane beam, so that the construction error of the elevation can be adjusted when the crane beam is installed, so as to prevent the error accumulation.The installation sequence of crane beam is as follows: installing crane beam, installing auxiliary truss and installing brake beam.(2) crane shall be used by slings, lashing or reliable clamps. The binding point shall be determined according to the weight and length of the crane beam. Generally, the angle of the sling shall be greater than 45 degrees at the ends of the center of gravity of the crane beam.(3) should be placed after the crane beam, the connecting plate is connected with the fixed edge plate and column crane girder structure, to prevent the crane hook loose after crane girder longitudinal and lateral movement of dumping.(4) crane beam correction should be performed in all bolts after installation, to prevent the installation of bolts when the crane beam shift change; prohibited welding in the crane girder under the flange and web on suspension and fixture.(5) adjust the elevation of the crane beam, correct the center line and span after titanium.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- Cable-stayed bridge, also called cable-stayed bridge, is a bridge that uses many cables to directly pull the bridge on the pylon. It is a structural system composed of a pressure tower, a tensile cable and a bent beam. It can be regarded as a multi span elastically supported continuous beam instead of a pier. The utility model can reduce the bending moment in the beam body, reduce the height of the building, lighten the weight of the structure and save the material.The cable-stayed bridge is composed of pylon, main girder and stay cable.

- Q: How to choose the right sling?

- The selection of rigging should be adapted to the kind of articles, environmental conditions and specific requirements.The sling to carry out strict inspection, in accordance with safety color to use, if found damaged sling can not be reused, need for scrap processing.The slings used for lifting operations must be of the same length.The sling shall not exceed its rated lifting capacity, and the sling shall not exceed its maximum safe working load.

- Q: What are the specifications for the rigging?

- Crane users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope. Fretting fatigue is the main cause of wire rope failure in atmospheric environment

Send your message to us

High Tensile Endless Eye Type Round Slings Customers Requiement Webbing Sling Type rh02

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches