WIRE ROPE WITH CRITICAL APPLICATIONS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: What are the dangerous sections of the crane hook?

- The sling tension A-A section on the one hand, the hook has straightened trend; also by the effect of bending moment on the other hand. Because the moment in this section, the bending stress is maximum, this section is a dangerous section.

- Q: Why do not different kinds or different sizes of slings and slings are used together?

- Choose proper slings and slings according to the specific conditions of the heavy loads; no heavy weights are allowed to be attached directly with the hooks, and no different kinds are allowed

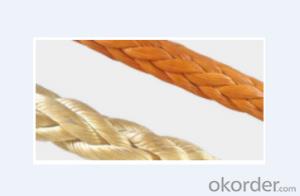

- Q: They are used for slings, ropes, chains, suspenders, hand hoists, right?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility of. According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q: How do you tie the wire rope?

- Manganese phosphating belongs to wear, corrosion, phosphating, automobile transmission, steel gear is through the manganese phosphating treatment, can ensure that the car gear for more than ten years without damage. Phosphating coating of steel wire rope China patent technology production, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just add the last bonderizing process, steel wire for rope wear resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope. The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of domestic smooth steel wire rope, wire rope surface is 2-3 times of imports, (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility, is currently the most advanced technology in the world of steel wire rope field. Manganese phosphating is bonderizing, can solve the problem of wire rope wear during use, smooth wire rope being eliminated, because the phosphating coating steel wire rope in short supply, the more sought after, need to ask a few companies.

- Q: What are the selection principles for lifting cranes?

- Selection should take into account the performance of the crane (ie operation capacity), ease of use, hoisting efficiency, hoisting capacity and duration requirements.

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 1 phosphating coating steel wire rope (patent products), steel phosphating manganese or zinc manganese by wire surface is very wear-resisting, effectively inhibit the occurrence of fretting wear, is a substitute for plain steel wire rope upgrade, service life far beyond the structure of smooth steel wire rope, wire rope including imported from developed countries such as Germany and Japan (currently the rope is about three times of phosphating, smooth rope after may also be able to improve the phosphating film 3-60 g / M 2, wire drawing no longer after phosphating processing, direct twisting wire rope), has been in China copycat wire rope technology innovation. The innovative technology is suitable for almost all kinds of high-quality carbon steel wire rope varieties, such as elevators, steel ropes, important use steel wire rope and so on.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- The cable-stayed bridge is a cable-stayed beam with a plurality of cable on the tower bridge. It consists of beam, cable and tower is composed of three parts. The cable-stayed bridge is a self anchored system, the level of power cable by Liang Chengshou, in addition to supporting beams on the pier, also supported by the cable leads to the tower. According to the materials used in the beam, they can be divided into steel cable-stayed bridge, composite beam cable-stayed bridge and concrete beam cable-stayed bridge.Cable stayed bridge is one of the most popular types of long-span bridges in china. So far, there are more than 3O cable-stayed bridges completed or under construction, second only to Germany and Japan, and the third place in the world. And the number of long-span concrete cable-stayed bridges has been ranked first in the world.In the middle of 50s, the first modern cable-stayed bridge was built in Sweden. For more than 40 years, the development of cable-stayed bridge has a strong momentum. In the middle of 70s, China began to build concrete cable-stayed bridges. After the reform and opening up, the momentum of the construction of cable-stayed bridges in China has been on the rise.

- Q: Which sling manufacturer is more reliable?

- Rigging is made of wire rope, plug or aluminium alloy head, and the key to the service life of the rigging is the quality of the wire rope.

- Q: What are the specifications for the rigging?

- Crane users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope. Fretting fatigue is the main cause of wire rope failure in atmospheric environment

- Q: Notice of tower crane?

- When the wind is above four, no lifting, installation or disassembly shall be carried out. Check the connection of all parts of the hydraulic jacking system before jacking up. No swing arm and other operations are prohibited during jacking.

Send your message to us

WIRE ROPE WITH CRITICAL APPLICATIONS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords