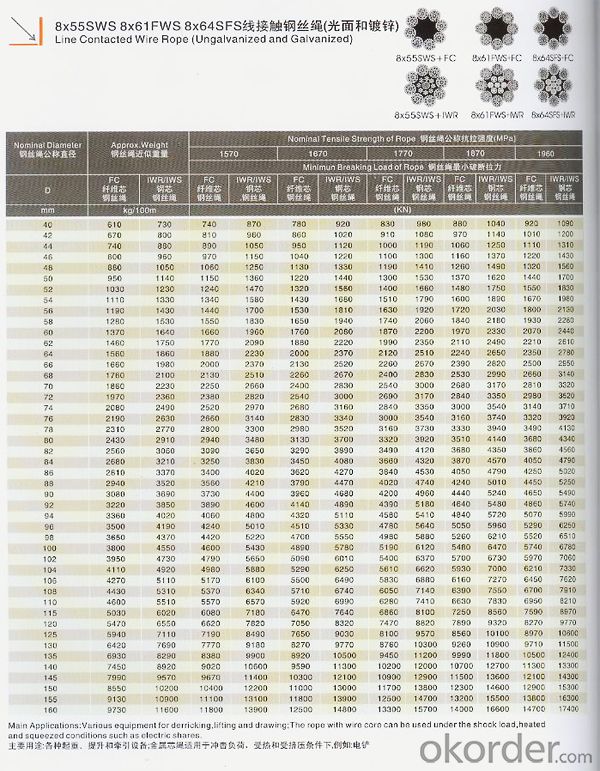

LINEAR CONTACT LAY WIRE ROPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: How is steel plate cut and shaped?

- Steel plate is typically cut and shaped using various methods such as plasma cutting, laser cutting, or shearing. Plasma cutting involves the use of a high-velocity jet of ionized gas to melt and remove metal, while laser cutting utilizes a high-powered laser beam to vaporize the material. Shearing, on the other hand, involves the use of a machine that applies a significant amount of force to cut through the steel plate. These techniques allow for precise and efficient cutting and shaping of steel plates to meet specific design requirements.

- Q: What are the applications of steel in the chemical industry?

- Steel has numerous applications in the chemical industry due to its exceptional properties. It is commonly used for constructing chemical storage tanks, pipelines, and equipment due to its high strength, durability, and resistance to corrosion. Steel is also utilized in the production of catalysts, reactors, and heat exchangers, where it can withstand high temperatures and pressure. Additionally, steel is an essential material for constructing industrial buildings, support structures, and platforms that house chemical manufacturing facilities.

- Q: What is the importance of steel reinforcement in concrete structures?

- The importance of steel reinforcement in concrete structures lies in its ability to enhance the strength and durability of the construction. Steel reinforcements, in the form of bars or mesh, are incorporated into the concrete to provide tensile strength, which concrete lacks. This reinforcement prevents cracking and structural failure under various loads, such as heavy weights or seismic activity. By improving the structural integrity, steel reinforcement ensures the longevity and safety of concrete structures, making them capable of withstanding extreme conditions and extending their lifespan.

- Q: How is steel used in the construction of parking structures and garages?

- Steel is commonly used in the construction of parking structures and garages due to its strength, durability, and versatility. It is used for the structural framework, such as columns, beams, and trusses, providing the necessary support and stability. Steel is also used for cladding, roofing, and flooring systems, ensuring a safe and weather-resistant environment. Additionally, steel allows for flexible and efficient designs, enabling the construction of multi-level parking structures and garages with minimal space requirements.

- Q: What are the different types of steel springs and their uses?

- There are several types of steel springs, each with their specific uses. Some common types include compression springs, extension springs, torsion springs, and flat springs. Compression springs are designed to resist compression forces and are used in applications such as automotive suspensions, mattresses, and industrial machinery. Extension springs, on the other hand, are designed to absorb and store energy when pulled apart and are commonly used in garage doors, trampolines, and various mechanical devices. Torsion springs provide a rotational force and are commonly found in clothespins, garage door systems, and various small appliances. Flat springs, also known as leaf springs, are used in applications that require high strength and flexibility, such as automotive suspensions, agricultural equipment, and heavy machinery. Each type of steel spring has its unique properties and applications, making them essential components in various industries.

- Q: What is the difference between hot rolled and cold rolled steel?

- The main difference between hot rolled and cold rolled steel lies in the manufacturing process. Hot rolled steel is formed at high temperatures, resulting in a rougher and less precise finish, while cold rolled steel is formed at lower temperatures, producing a smoother and more refined surface. This difference in processing also affects the steel's mechanical properties, with hot rolled steel generally being more malleable and ductile, while cold rolled steel tends to be stronger and harder.

- Q: How is steel used in the production of HVAC systems?

- Steel is commonly used in the production of HVAC systems due to its strength, durability, and resistance to corrosion. It is utilized to fabricate various components such as ductwork, pipes, and heat exchangers, ensuring the system's structural integrity and longevity.

- Q: What are the different types of steel coatings for corrosion prevention?

- There are several types of steel coatings available for corrosion prevention, including galvanized coatings, metallic coatings, organic coatings, and ceramic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface to provide a protective barrier against corrosion. Metallic coatings, such as aluminum or zinc-aluminum, offer excellent corrosion resistance due to their sacrificial properties. Organic coatings, such as epoxy or polyurethane, create a protective film on the steel surface to prevent contact with corrosive elements. Ceramic coatings, like porcelain enamel or vitreous enamel, offer high resistance to corrosion, chemicals, and extreme temperatures. Each type of coating has its advantages and suitability for specific applications.

- Q: What are the different grades of steel?

- There are several different grades of steel, including carbon steel, alloy steel, stainless steel, tool steel, and high-speed steel. Each grade has its own unique composition and properties, making them suitable for different applications and industries.

- Q: What are the different types of steel bolts and their uses in automotive assembly?

- There are several types of steel bolts commonly used in automotive assembly, including hex bolts, flange bolts, carriage bolts, and shoulder bolts. Hex bolts are the most common type and are used for general fastening purposes. Flange bolts have a wider surface area and are designed to provide a secure connection between parts. Carriage bolts have a rounded head and are often used in applications where aesthetics are important. Shoulder bolts have a shoulder between the head and the threaded portion, allowing for precise alignment and controlled movement. Each type of bolt serves a specific purpose in automotive assembly, ensuring the structural integrity and functionality of the vehicle.

Send your message to us

LINEAR CONTACT LAY WIRE ROPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords