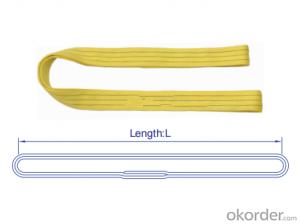

Closed cord,Apply to tensile cables, stay cable and hanger cables.

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 set

- Supply Capability:

- 0 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

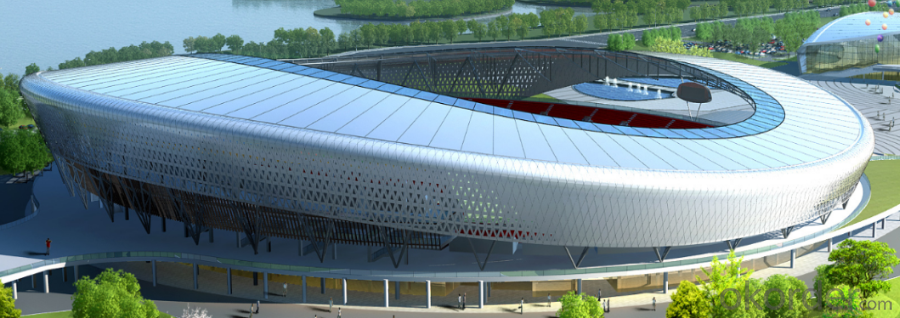

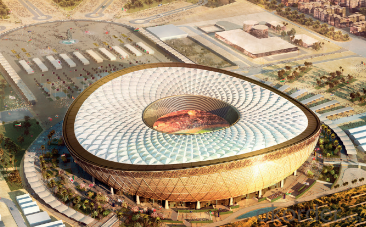

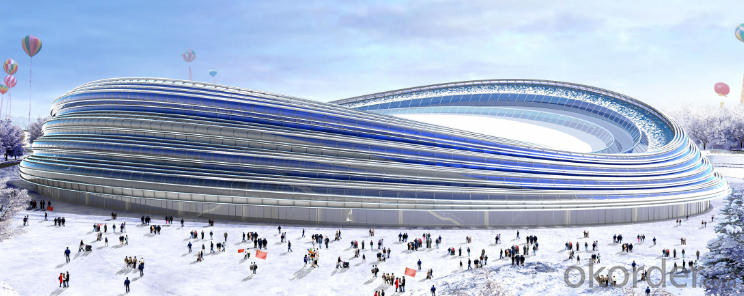

Closed cables are mainly used in stadiums。

Cable

Cable factory is the only one integrated professional company in China that specializes in cable manufacturing, testing and installation owning two PWS production lines and one PPWS production line, the main products include cable for bridge structure, cables for tensile structure, PPWS cable and all kinds of anchorages. The largest size is up to Φ7x649.

Cable factory has acquired a lot of international scientific and technological achievements and national patents.

Cable factory even participated the editing of many standards, like cable for architectural construction, cable structure technical regulations, membrane structure construction quality acceptance regulations and prestressed steel structure technical regulation.

Production Cap acity

KS8/2500, the biggest cabling machine in China, it is used for the production of large diameter, long length and super heavy steel wire ropes with maximum capacity of 350t. With the most baskets, the stranding machine of KGT72/630 is mostly used for production of line contact wire ropes and large diameter spiral strands.

- Q: How much is the crane arm of the tower from the residential building recently?

- (1) the drivers and signaling personnel of the tower cranes must be specially trained and issued certificates by the relevant departments, and attention should be paid to whether the type of tower used by the driver is consistent with the actual tower type.(2) special person special plane management, Captain responsibility system, and strict shift shift system.(3) the newly installed or repaired tower crane must perform the machine test operation according to the specifications.(4) tower crane should keep a safe distance from overhead transmission lines.(5) driver's room should be equipped with fire extinguishing equipment.

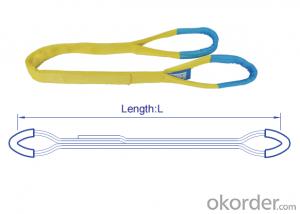

- Q: Which brand is better for imported rigging?

- Germany's mechanical products are better, quality world-class, CarlStahl sling rigging is Germany's old brand.

- Q: Why do not different kinds or different sizes of slings and slings are used together?

- Choose proper slings and slings according to the specific conditions of the heavy loads; no heavy weights are allowed to be attached directly with the hooks, and no different kinds are allowed

- Q: What does the inspection of rigging involve?

- Galvanized steel wire rope, including hot galvanized and galvanized two kinds, galvanized zinc layer is thick corrosion resistant ability is strong, the thickness of zinc in grams / square meter said.

- Q: What torture refers to the lever and the sling

- This is a torture peculiar to china. The knee joint has the smallest range in the major joints of the limbs, and the length of both ends of the thigh and leg is favorable to the prisoners. The lever principle is used to compel the victims with lesser intensity. Key points of anti joint using tiger stool:1, the victims in the sitting position (arms tied or tied into the penalty, the pulling force cross) it will aggravate the leg ligament, and supine position due to hip joint ligament relaxation, legs relaxed, will weaken the degree of pain;2, the leg is tied in the lap of the thigh, rather than the following parts. Because the function of the tiger stool is to pull the joints and ligaments of the victim's leg and to cause a dislocated knee, not to break the victim's leg. Because the broken leg, the fibula needs a lot of power, the pain time is short (the victim will soon fainted), do not meet the punishment, both to torture the victims and their own labor saving requirements.According to records, when the victim is on a tiger stool, he usually gets sweaty when he pad three bricks. When the five bricks are completely dislocated, the person will faint. The torturer usually each brick will be suspended for a while, the victims of the pain continued for a period of time after aggravated torture efforts. Women's ligaments are usually softer than men, so they suffer longer on tiger stools and tend to faint when they are added to six bricks, the longest of which is eight bricks.

- Q: Slings and rigging manufacturers, which cost-effective?

- Crane users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope. The use of wire rope in the atmospheric environment, mainly caused by the failure of wire rope is fretting fatigue, at present, the wire rope for the first time in the field of fretting fatigue control measures is the phosphating coating steel wire rope patent technology production, steel wire after manganese phosphating or zinc manganese treatment, wear resistance, enhance the surface of steel wire that is not easy to wear and corrosion fatigue life of the steel wire rope large increase, fatigue life is three times the same structure of plain steel wire rope, the highest test value has reached an alarming four times contrast (laboratory comparable conditions), can be verified by fatigue test, fatigue test machine if they have on their own contrast test, this test results the most credible, the service life of wire rope and the fatigue life is directly proportional to the fatigue life, long service life of the same proportion of extension.

- Q: Is the sling the same thing as the rigging?

- I have also struggled with this concept before, and I consulted the professionals specializing in rigging. I say you should be able to understand the sling, lifting heavy rigid fetching device operation means, that is to say can directly take hanging items, mainly include: grab, clamp, suction and special sling and rigging, etc.; refers to the lifting items, tie hook combination device with flexible. In the article, usually made from high strength flexible parts (steel wire rope, lifting chain, artificial fiber tape) with end ring, hook, shackle assembly.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- Cable-stayed bridge, also called cable-stayed bridge, is a bridge that uses many cables to directly pull the bridge on the pylon. It is a structural system composed of a pressure tower, a tensile cable and a bent beam. It can be regarded as a multi span elastically supported continuous beam instead of a pier. The utility model can reduce the bending moment in the beam body, reduce the height of the building, lighten the weight of the structure and save the material.The cable-stayed bridge is composed of pylon, main girder and stay cable.

- Q: Which sling manufacturer is more reliable?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q: What are the specifications for the rigging?

- Crane users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope. Fretting fatigue is the main cause of wire rope failure in atmospheric environment

Send your message to us

Closed cord,Apply to tensile cables, stay cable and hanger cables.

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 set

- Supply Capability:

- 0 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches