2015 Full and Semi automatic glass cutting machine Hot selling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

We are a high-tech enterprise specialized in the research, manufacture and sale of Aluminum-PVC door & window production equipment,glass processing equipment. Our products sell very well in China and are exported to many foreign countries and regions.

We have many experienced technical engineers and experts who have been worked in this industry for many years.

2. Technical parameter:

- Mn bridge steel (Q345A ), perfect surface treatment

-Optimized table structure makes sure the stable table, dynamic balance and mechanics intensity perfectly matched

- Cutting pressure automatic adjusted according to glass thickness

-Cutter head 360 degree rotating

-Climbing wheels on the cutter head for protecting the cutter assembly and the glass

-Water proof surface panel, stainless steel side covered, water and deformation resisting

- High quality felt, perfect level, anti-static

-Automatic side locating system, pneumatic mechanical and photoelectric joint locating

-Self-lubricating guide rail

-Air filter for keeping the oil clean

-Air float and belt transmit

-Linear guide rail

-Automatic oiling for transmission system

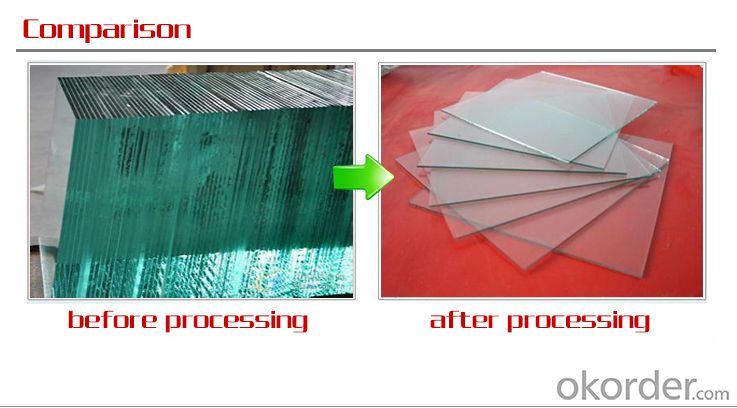

3. Features of our Machine Line

CNC Auto Glass Cutting Machine Production Line adopt the most advanced Italy software.

Use imported high precision rack, slider and servo-motor, can be operated longer and faster.

CNC process control system, photoelectric positioning, convenient and accurate, airbag cutting, smooth precision.

Applicable to construction curtain walls, auto windshield, crafts, furniture, hollow, solar glass, etc, or set cutting for linear or special-shaped glass.

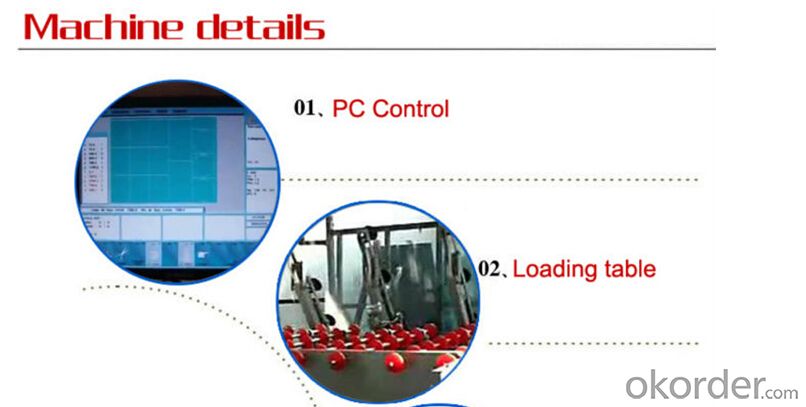

4. Main Introduction: Automatic glass loading machine

If the product quality does not meet the standards set in your contract, Alibaba.com will refund the covered amount of your payment. On-time shipment protection

If your products are not shipped on time as per your contract, Alibaba.com will refund the covered amount of your payment. Payment protection

If the supplier breaks the on-time shipment or product quality terms of your contract, Alibaba.com will refund the covered amount of your payment. Product Details Company Profile Transactions History.

Report Suspicious Activity Company Information Packaging & Shipping Our Services FAQ Quick Details Condition: New Machine Type: Insulating Glass Production Line Production Capacity: 1200piece/day

Place of Origin: Shandong, China (Mainland)Brand Name: PARKER Model Number: IGV22

Voltage: 220-380v 50hzPower(W): 23.7kwDimension(L*W*H): 21000x2100x3300mm

Weight: 4800kgsCertification: CE Warranty: 1 years

5. Our Service for our customers

Packing and shipping

Packaging Detail: in plastic film and container

Delivery Detail: 30-60 days once receiving from the first payment

Payment terms

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q: What kind of equipment does the toughened glass production line include?

- Tempered glass production line: upper panel of control system, heating furnace body, wind spring, lower piece, typhoon machine, air compressor

- Q: Can plexiglass be machined with CNC milling machines?

- It is usually done with laser engraving machines and mechanical engraving machines.In fact, the laser engraving machine works best.

- Q: How much is the mini toughened glass factory and what other equipment?

- 1, site requirements1.1 production placeProduction workshop: the production workshop has five parts: raw material area, processing area, glass tempering furnace, finished product area and turnover zoneRaw material area: according to the specifications of the products, the raw materials should be about 500 square meters;Processing area: dicing, cleaning, grinding, drilling, about 280 square meters area;Tempering furnace: the main part of the production line, about 200 square meters area (if it is continuous furnace is greater);Finished area: glass after the completion of acceptance, approval, engraved logo size is about 300 square meters;After the completion of the whole product, according to the customer order request delivery, send about 400 square meters.

- Q: What are the processing methods of organic glass?

- Important points in hot bending of perspex:A. if you want to use water heating, do not "direct" heating by boiling, and use indirect heating so as not to change the size after moisture absorption.B. fixtures should be "level, smooth and clean" so as to avoid residual plastic lines and affect transparency.C. heating rate should not be too fast, should not exceed the thermal deformation temperature.D. cooling, the temperature of each part of the workpiece should be consistent. So the cooling rate is not too fast, otherwise heart with epidermal temperature difference caused by thermal stress, loosen fixture after deformation and back. Therefore, the cooling rate should not be too fast, the furnace will be better cold.The size of the E. after heat treatment will change slightly due to the two contraction, and the temperature should not be too high to reduce the shrinkage size.F. don't iron it, it will deform much more!G. specific heating time and temperature, it is necessary to experiment several times in order to master the best temperature, time.

- Q: What equipments are used in glass production?

- There are a lot of the original film production, drawing machine, annealing furnace, cutting machine (cutting, slitting), conveyor, stacking machine, machine hand,..... A lot of equipment, glass processing upstairs two ranked almost, mainly depends on what kind of glass you produce

- Q: Do you use UV flatbed printers for glass processing?

- UV flatbed printer according to the printing efficiency and configuration performance of different, the price between 1-60w all, equipment manufacturers and card research and development center in Hangzhou. Finally, it is important to note that when you buy equipment, you need to pay attention to refitting equipment and original equipment.

- Q: I want to buy a glass grinder to process glass granules, but there is no market. Please point out the market for our predecessors

- Personally, can be made into handicrafts, with pieces of homegrown, can do a good job in Taobao to sell, pay attention to product packaging!

- Q: Is it complicated to produce double glass? We invest about how much money?

- The raw material for making glass is to enter the glass tube without melting it. There are technical staff sealing, if not good, so do out of the cup is not good, scrap rate will be very high.

- Q: How much does a set of insulating glass aluminum strips require?

- Look at your finances. If you want a vertical one, it's more expensiveIf it is ordinary, two machines can be about 3W

- Q: Can glass fiber board be cut with laser cutting machine?

- Glass fiber; glass fiber board; FR4 reinforcing plate; FR-4 epoxy resin board; flame retardant insulation board; epoxy plate, FR4 plate; glass board; PCB drilling pad.

Send your message to us

2015 Full and Semi automatic glass cutting machine Hot selling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches